Biphasic catalyst, preparation method thereof and application of biphasic catalyst in lignocellulose biomass conversion

A technology of lignocellulose and catalyst, applied in the conversion of lignocellulose biomass, two-phase catalyst and its preparation field, can solve the problems of a large amount of waste acid and alkali, equipment corrosion, harsh operating conditions, etc., and achieve equipment corrosion The effect of low cost, reduced processing cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

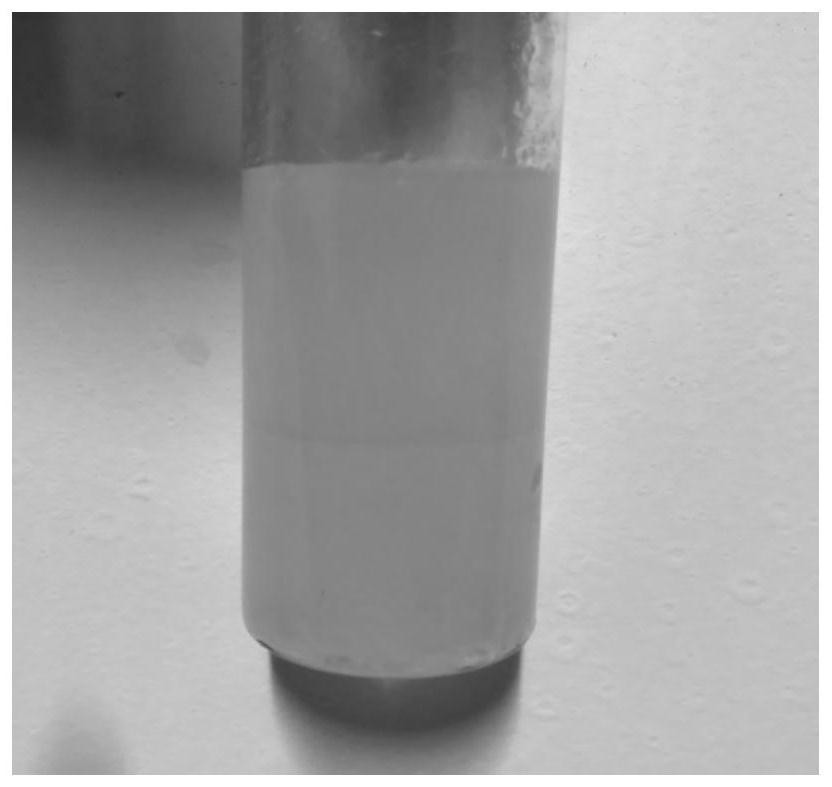

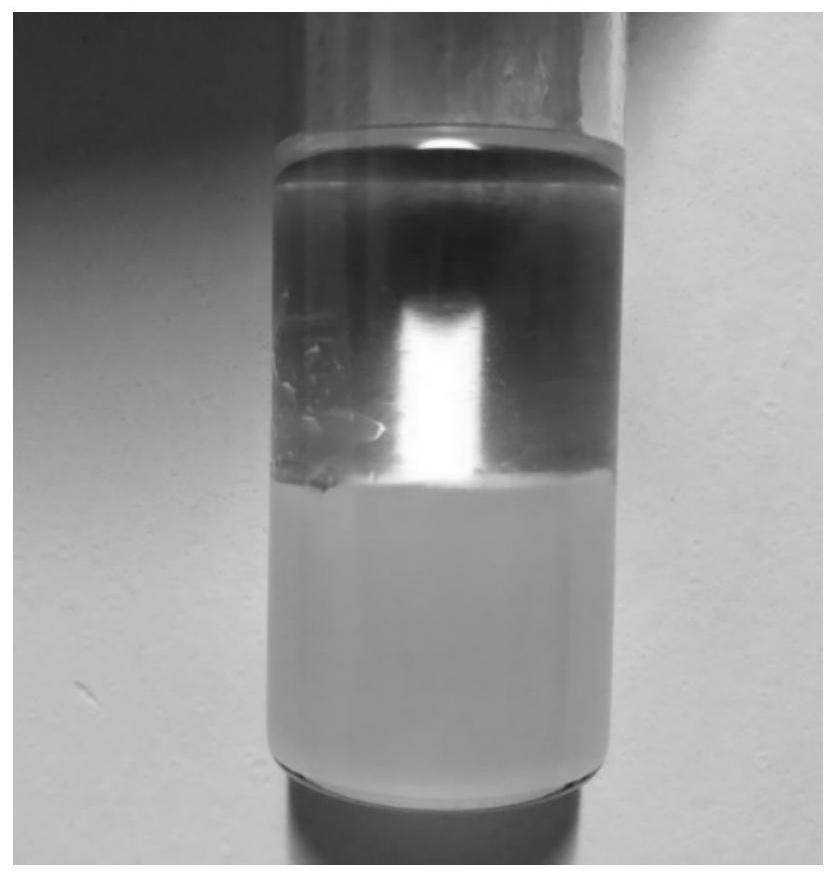

Image

Examples

Embodiment 1

[0044]Embodiments of the present invention provide a dual-phase catalyst, comprising a hydrophilic phase and a hydrophobic phase, wherein the hydrophilic phase is composed of tetrabutylammonium bromide and FeCl with a molar ratio of 3:1 3 ·6H 2 A deep eutectic solvent composed of O, and the hydrophobic phase is a deep eutectic solvent composed of tetraphenylammonium borate and capric acid in a molar ratio of 10:1.

[0045] The preparation method of above-mentioned biphasic catalyst comprises the steps:

[0046] Step a, according to design ratio, with 0.6mol tetrabutylammonium bromide and 0.2mol FeCl 3 ·6H 2 O mixed evenly, heated to 65°C, and stirred at constant temperature for 2 hours to obtain a uniform and transparent hydrophilic phase;

[0047] Step b, according to the design ratio, mix 0.5mol tetraphenylammonium borate and 0.05mol capric acid evenly, heat to 100°C, and stir at constant temperature for 2.5h to obtain a uniform and transparent hydrophobic phase;

[0048...

Embodiment 2

[0057] Embodiments of the present invention provide a dual-phase catalyst, comprising a hydrophilic phase and a hydrophobic phase, wherein the hydrophilic phase is composed of (1-butyl) triethylammonium bromide and FeCl with a molar ratio of 1:1 3 ·6H 2 A deep eutectic solvent composed of O, and the hydrophobic phase is a deep eutectic solvent composed of ammonium phosphomolybdate and capric acid with a molar ratio of 5:1.

[0058] The preparation method of above-mentioned biphasic catalyst comprises the steps:

[0059] Step a, according to design ratio, with 0.6mol (1-butyl) triethyl ammonium bromide and 0.6mol FeCl 3 ·6H 2 O mixed evenly, room temperature 25 ° C, constant temperature stirring for 3 hours, to obtain a uniform and transparent hydrophilic phase;

[0060] Step b, according to the design ratio, mix 0.2mol ammonium phosphomolybdate and 0.04mol capric acid evenly, and stir at a room temperature of 25°C for 5 hours at a constant temperature to obtain a uniform an...

Embodiment 3

[0066] Embodiments of the present invention provide a dual-phase catalyst, comprising a hydrophilic phase and a hydrophobic phase, wherein the hydrophilic phase is composed of tetrapropylammonium bromide and FeCl in a molar ratio of 6:1 3 ·6H 2 A deep eutectic solvent composed of O, and the hydrophobic phase is a deep eutectic solvent composed of cetyltrimethylammonium bromide and capric acid in a molar ratio of 4:1.

[0067] The preparation method of above-mentioned biphasic catalyst comprises the steps:

[0068] Step a, according to design ratio, with 0.6mol tetrapropyl ammonium bromide and 0.1mol FeCl 3 ·6H 2 O mixed evenly, heated to 68°C, and stirred at constant temperature for 2.5h to obtain a uniform and transparent hydrophilic phase;

[0069] Step b, according to the design ratio, mix 0.2mol cetyltrimethylammonium bromide and 0.05mol capric acid evenly, heat to 75°C, and stir at constant temperature for 3.0h to obtain a uniform and transparent hydrophobic phase;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap