Differential flotation process for sphalerite

A sphalerite and flotation technology, used in flotation, solid separation, etc., can solve the problems of high chemical cost, lead flotation interference, large metal loss, etc. The effect of improving the volume and quality of the foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A complex sulfur-oxygen mixed refractory lead-zinc ore in Guangxi contains light gangue minerals such as dolomite and calcite with a mineral content of about 60%. At the same time, due to the fine-grained distribution of useful minerals, the embedded distribution characteristics and symbiotic relationship are complex; After grinding the ore whose grinding fineness is -0.074mm and accounts for 70%-75% of the total ore content, there are still a large number of associated organisms. If the fineness of ore grinding is simply increased, it will cause accelerated mudification of light gangue minerals, resulting in an increase in the dosage of flotation agents, deterioration of indicators, waste of natural resources, and is not conducive to the economic benefits of enterprises.

[0030] At present, after the completion of the lead selection operation, the zinc selection process is a sequence of roughing, second sweeping and fourth fineness returning to the process. The above-...

Embodiment 2

[0042]The ore selected in this embodiment is a large amount of fine-grained sulfur-oxygen mixed complex refractory lead-zinc sulfide ores such as dolomite and calcite. The raw ore contains 0.74% lead, 2.81% zinc, 6.9% sulfur, and 62% dolomite; The metal minerals of the ore are mainly pyrite, sphalerite, galena, pyrite, white lead ore and trace tetrahedrite, bornite, magnetite, smithsonite, arsenopyrite, etc. The gangue minerals are mainly dolomite, followed by barite, a small amount of quartz, garnet, calcite, feldspar, gypsum, mica and trace amounts of apatite, kaolinite, tourmaline, etc. The main metal minerals have fine intercalation particle size, complex relationship and low monomer dissociation degree.

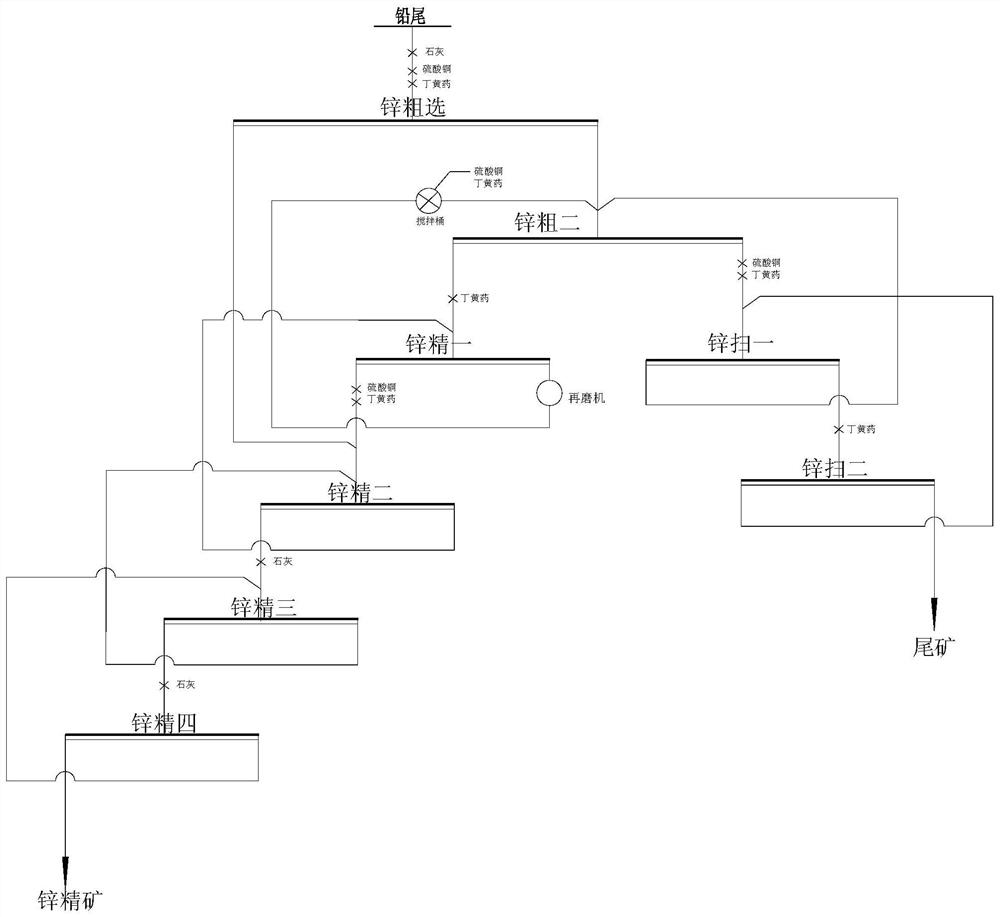

[0043] This embodiment provides a fractional speed flotation process of sphalerite, according to the attached figure 1 The ore is processed by the beneficiation process shown, and the beneficiation steps are as follows:

[0044] (1) Ore preparation, ore grinding, and l...

Embodiment 3

[0053] The ore selected in this embodiment is a large amount of fine-grained sulfur-oxygen mixed complex refractory lead-zinc sulfide ores such as dolomite and calcite. The raw ore contains 0.81% lead, 2.70% zinc, 6.9% sulfur, and 59% dolomite; The metal minerals of the ore are mainly pyrite, sphalerite, galena, pyrite, white lead ore and trace tetrahedrite, bornite, magnetite, smithsonite, arsenopyrite, etc. The gangue minerals are mainly dolomite, followed by barite, a small amount of quartz, garnet, calcite, feldspar, gypsum, mica and trace amounts of apatite, kaolinite, tourmaline, etc. The main metal minerals have fine intercalation particle size, complex relationship and low monomer dissociation degree.

[0054] This embodiment provides a fractional speed flotation process of sphalerite, according to the attached figure 1 Shown beneficiation process processes this ore, concrete steps are as follows:

[0055] (1) Ore preparation, ore grinding, and lead sorting operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com