Photocathode material for preparing formic acid by reducing CO2 and preparation method thereof

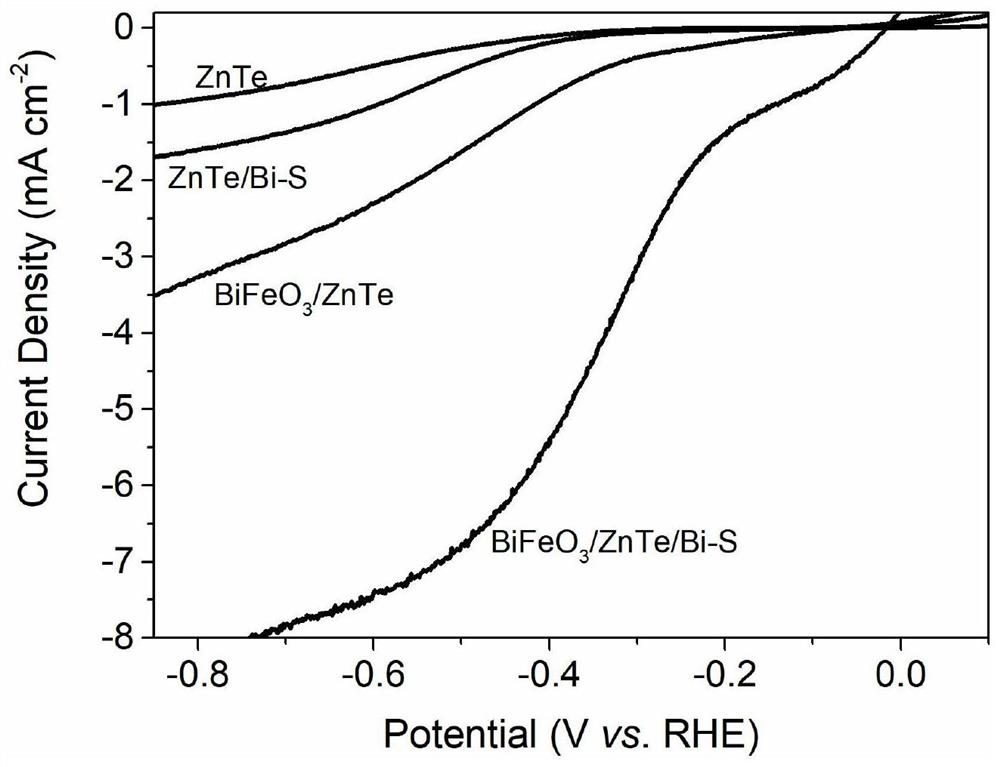

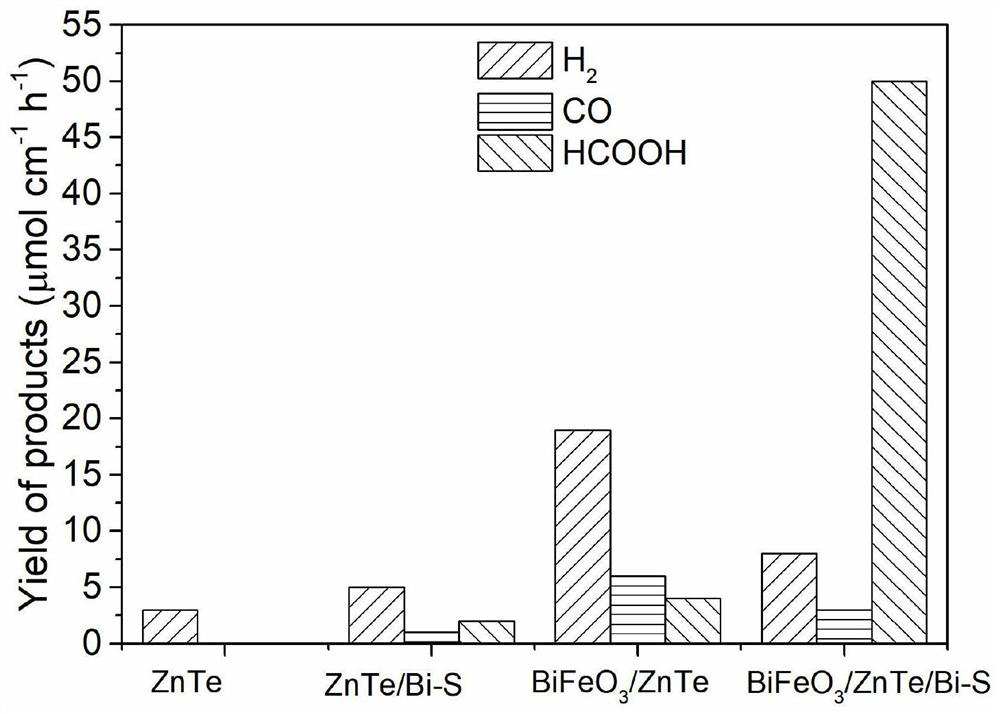

A technology of photocathode and formic acid, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, artificial filaments of inorganic raw materials, etc. It can solve the problems of limited separation efficiency of photogenerated charges, reduction of reaction overpotential, and decline of electron reduction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for CO 2 A method for preparing a photocathode material for reducing formic acid, comprising the following steps;

[0029] mixing bismuth nitrate, ferric nitrate, citric acid, water and polyvinylpyrrolidone to obtain a spinning solution;

[0030] The polyvinyl alcohol aqueous solution is spin-coated onto the FTO surface to obtain a spinning substrate;

[0031] performing electrospinning on the surface of the spinning substrate by using the spinning solution to obtain three-dimensional nanofibers;

[0032] The three-dimensional nanofibers were calcined to obtain BiFeO 3 Nanofiber photoelectrodes;

[0033] With the BiFeO 3 The nanofiber optoelectronic electrode is used as the substrate, and ZnTe is used as the evaporation source to conduct evaporation coating to obtain ZnTe-loaded BiFeO 3 electrode;

[0034] BiCl 3, thioacetamide and dimethylformamide were mixed, and the ZnTe-supported BiFeO 3 The electrode is subjected to h...

Embodiment 1

[0056] Weigh 0.78g of bismuth nitrate, 0.48g of ferric nitrate and 0.1g of citric acid respectively, add them into 10mL of deionized water, and stir to dissolve. Then 0.6 g of polyvinylpyrrolidone was added and stirred overnight to obtain a spinning solution. The FTO glass was fixed on the drum of the electrospinning device, and the aqueous solution of polyvinyl alcohol was spin-coated on the FTO surface before spinning to enhance the adhesion of FTO. Pour the spinning solution into the syringe, and set the parameters of the electrospinning process: the spinning voltage is 20kV, the drum speed is 150r / min, and the propulsion speed is 2mm / h, and three-dimensional nanofibers are obtained. Subsequently, the fiber was taken out and placed in a muffle furnace at 700°C for calcination for 5 hours to obtain BiFeO 3 nanofiber photoelectrode; the above BiFeO 3 The nanofiber photoelectrode is fixed on the substrate of the thermal evaporation coating machine, with ZnTe as the evaporati...

Embodiment 2

[0062] Weigh 1.17g of bismuth nitrate, 0.72g of ferric nitrate and 0.2g of citric acid respectively, add them into 10mL of deionized water, and stir to dissolve. Then 0.8 g of polyvinylpyrrolidone was added and stirred overnight to obtain a spinning solution. The FTO glass was fixed on the drum of the electrospinning device, and the aqueous solution of polyvinyl alcohol was spin-coated on the FTO surface before spinning to enhance the adhesion of FTO. Pour the spinning solution into the syringe, and set the parameters of the electrospinning process: spinning voltage 18kV, drum speed 200r / min, and propulsion speed 2mm / h, to obtain three-dimensional nanofibers. Subsequently, the fiber was taken out and placed in a muffle furnace at 800°C for calcination for 3 hours to obtain BiFeO 3 nanofiber photoelectrode; the above BiFeO3 The nanofiber photoelectrode is fixed on the substrate of the thermal evaporation coating machine, with ZnTe as the evaporation source, the vacuum in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com