Electrodeposition MOF-derived HKUST-1-LDH super capacitor electrode material and preparation method thereof

A HKUST-1-LDH, HKUST-1 technology, applied in the field of HKUST-1-LDH supercapacitor electrode materials and their preparation, can solve the problems of low conductivity, poor cycle performance, hinder the development of electrode materials, etc., and achieve large BET Specific surface area, mild conditions, simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

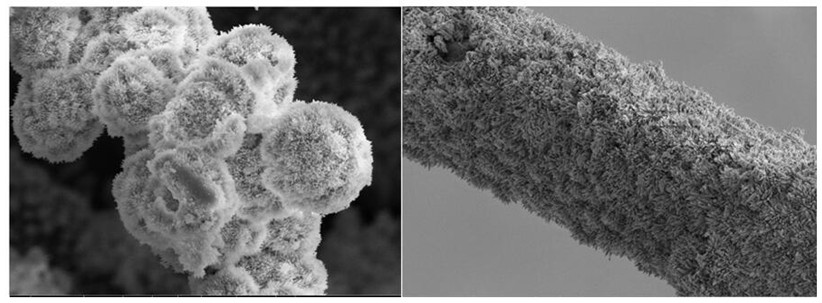

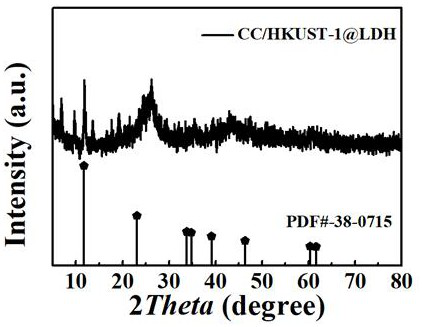

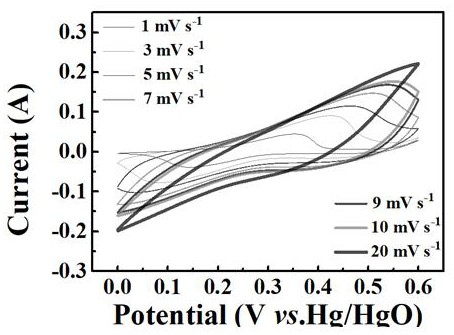

Image

Examples

Embodiment 1

[0028] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 1*2cm 2 Then arrange the carbon in the lining of the polytetrafluoroethylene reactor containing concentrated nitric acid solution, seal it completely and put it into the oven. After natural cooling, use acetone, deionized water, and absolute ethanol to repeatedly ultrasonically clean for 30 minutes, dry at room temperature, and then set aside for later use.

[0029] Step 2, a certain quality of soluble copper salt trihydrate copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, 0.49g), organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.24g), deionized water (5mL), absolute ethanol (C 2 h 5 OH, 5mL), N,N-dimethylformamide (DMF, 2mL) and glacial acetic acid (CH 3 COOH, 1mL); Stirring time 10min. Gained mixed solution A.

[0030] Step 3. Transfer the mixed solution A obtained in step 2 into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reactor, place the reactor in an oven at a...

Embodiment 2

[0036] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 1*2cm 2 Then arrange the carbon in the lining of the polytetrafluoroethylene reactor containing concentrated nitric acid solution, seal it completely and put it into the oven. After natural cooling, use acetone, deionized water, and absolute ethanol to repeatedly ultrasonically clean for 30 minutes, dry at room temperature, and then set aside for later use.

[0037] Step 2, a certain quality of soluble copper salt trihydrate copper nitrate (Cu(NO 3 ) 2 ·H 2 O, 0.49g), soluble organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.24g), deionized water (5mL), absolute ethanol (C 2 h 5 OH, 5mL), N,N-dimethylformamide (DMF, 2mL) and glacial acetic acid (CH 3 COOH, 3 mL); solution A was obtained.

[0038] Step 3. Transfer the solution A obtained in step 1 into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reactor, place the reactor in an oven at a temperature of 55°C,...

Embodiment 3

[0044] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 1*2cm 2 Then arrange the carbon in the lining of the polytetrafluoroethylene reactor containing concentrated nitric acid solution, seal it completely and put it into the oven. After natural cooling, use acetone, deionized water, and absolute ethanol to repeatedly ultrasonically clean for 30 minutes, dry at room temperature, and then set aside for later use.

[0045] Step 2, a certain quality of soluble copper salt trihydrate copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, 0.49g), soluble organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.24g), deionized water (5ml), absolute ethanol (C 2 h 5 OH, 5mL), N,N-dimethylformamide (DMF, 2mL) and glacial acetic acid (CH 3 COOH, 3 mL); the resulting solution A.

[0046] Step 3. Transfer the solution A obtained in step 2 into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reactor, place the reactor in an oven at a temperature of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com