Method for enhancing selective permeability of reverse osmosis membrane by adjusting pore size of base membrane

A reverse osmosis membrane and permeability technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as unfavorable exploitation and use, groundwater too deep from the surface, etc., to improve water flux and salt retention. rate, less defects, good cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for enhancing the permeability selectivity of a reverse osmosis membrane by adjusting the basement membrane pore size, comprising the following steps:

[0032] 1) Preparation of casting solution: put 1.2g of polysulfone particles (produced by Solvay Specialty Polymer Co., Ltd., USA) and 8.8g of organic solvent N,N-dimethylformamide into a round bottom flask, heat and stir until Completely dissolve to obtain the casting solution; after standing the casting solution for degassing for 24 hours, set aside;

[0033]2) Preparation of the base film: spread the non-woven fabric on a flat glass plate, and then evenly coat the casting solution after step 1) degassing on the non-woven fabric (the non-woven fabric is produced by Mitsubishi Corporation of Japan, the same below. ), make the casting solution fully infiltrate the non-woven fabric, and use a scraper to scrape off the excess liquid evenly on the surface of the non-woven fabric to form the bottom film layer; then...

Embodiment 2

[0038] The preparation process of the reverse osmosis membrane in Example 2 was repeated in Example 1, the difference being that "step 1) of Example 2 was replaced by 1.4g of polysulfone particles and 8.6g of organic solvent N,N-dimethyl Formamide was put into a round-bottomed flask, heated and stirred until it was completely dissolved to obtain a casting solution; the casting solution was allowed to stand for degassing for 24 hours, and then it was ready for use”. The final film number was named M-14.

Embodiment 3

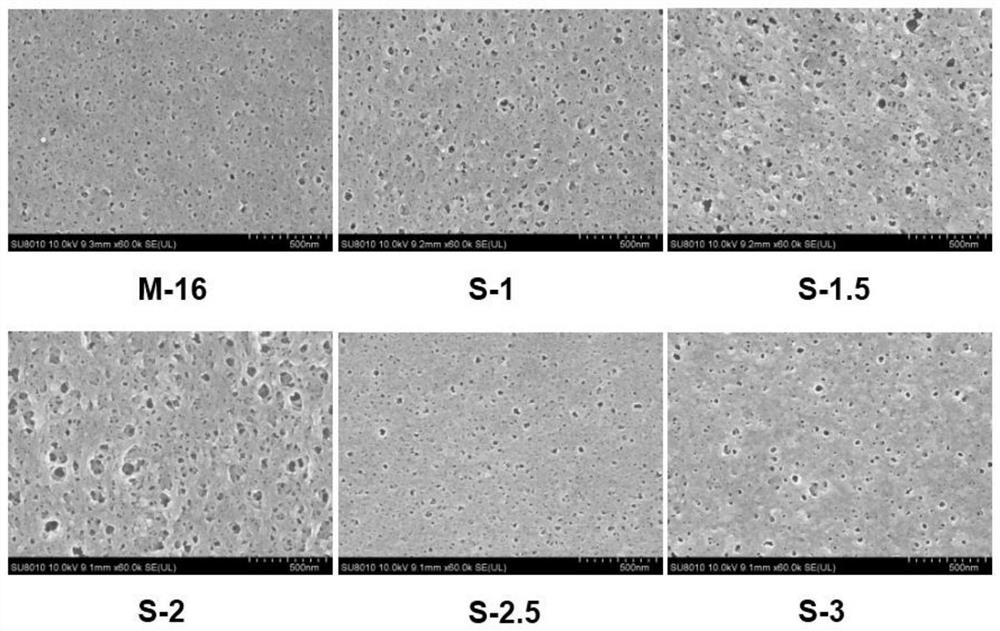

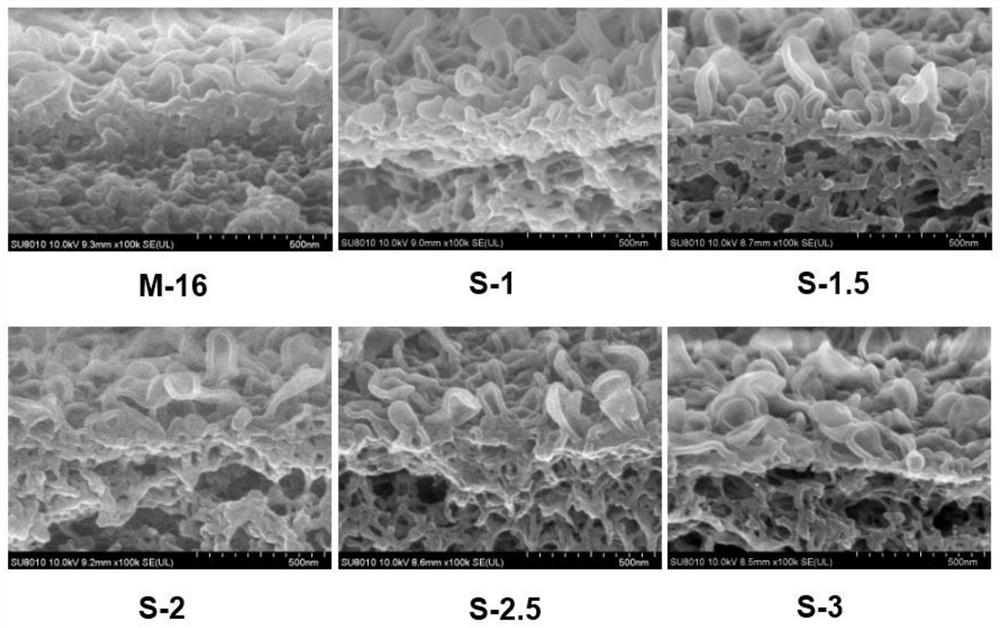

[0040] Example 3 The preparation process of the reverse osmosis membrane was repeated in Example 1, the difference being that "step 1) of Example 3 was replaced with 1.6g of polysulfone particles and 8.4g of organic solvent N,N-dimethylformaldehyde Put the amide into a round-bottomed flask, heat and stir until it is completely dissolved to obtain a film-casting solution; leave the film-casting solution to defoam for 24 hours, and then set aside." The number of the finally prepared membrane was named M-16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com