A kind of acid thickener and its preparation method and application

A technology of acid thickener and chain extender, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of good shear stability, strong thickening ability, and increased force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076]Specifically, in some embodiments, the raw materials for the preparation of functional monomers may include 2-(chloromethyl)benzoyl chloride and N,N-dimethylhexadecylamine, N,N-dimethyldodecylamine One of alkylamine, N,N-dimethyltetradecylamine, and the functional monomer synthesis method includes the following steps: pre-add the reaction equipment in the reaction equipment equipped with electric stirrer, thermometer and nitrogen protection device Solvent dichloromethane, mix 2-(chloromethyl)benzoyl chloride with N,N-dimethylhexadecylamine, N,N-dimethyldodecylamine, N,N-dimethyl One of the tetradecylamines is added to the reaction equipment. After purging nitrogen and removing oxygen, heat up to about 30-50°C while stirring, and react for 8h-12h to prepare preliminary functional monomers; add a small amount of triethanolamine to the prepared preliminary functional monomers for adsorption reaction Generated hydrogen chloride gas, then add a certain amount of hydroxyethyl...

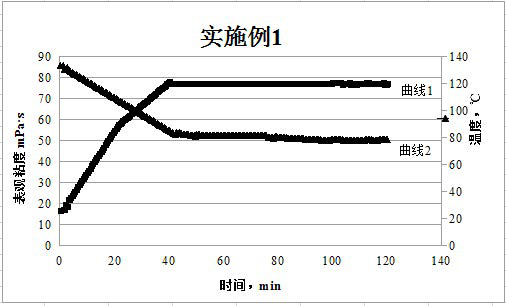

Embodiment 1

[0108] 1. An acid thickener prepared from the following components in parts by weight:

[0109] 40 parts of acrylamide, 80 parts of functional monomer, 350 parts of methacryloyloxyethyltrimethylammonium chloride, 0.8 part of chain extender polyethylene glycol diacrylate, surfactant oleic acid amidomethyl hydroxypropyl 15 parts of ammonium chloride, 0.13 parts of initiator (0.1 part of azobisisobutylamidine hydrochloride, 0.02 part of ammonium persulfate, 0.01 part of sodium bisulfite) and 500 parts of water;

[0110] Wherein, the functional monomer is prepared by reacting 2-(chloromethyl)benzoyl chloride and N,N-dimethylhexadecylamine and then esterifying with hydroxyethyl acrylate.

[0111] 2, a kind of preparation method of acid thickener, comprises the following steps:

[0112] (1) Preparation of functional monomers: 70 grams of dichloromethane, 38 grams of 2-(chloromethyl)benzoyl chloride and 27 grams of N,N- Dimethylhexadecylamine, after passing nitrogen to remove oxyge...

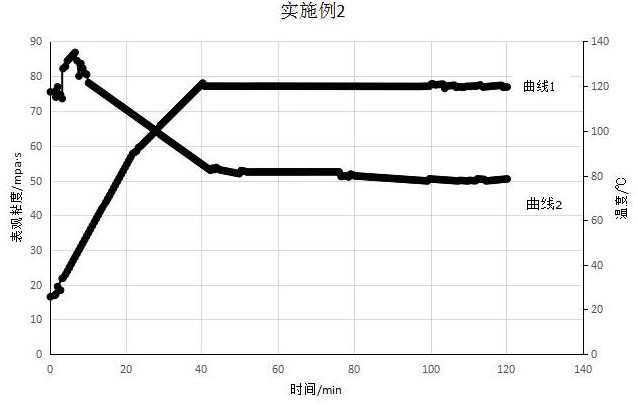

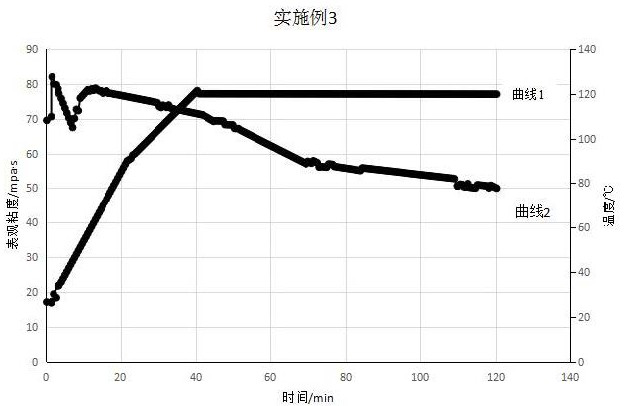

Embodiment 2

[0117] 1. An acid thickener prepared from the following components in parts by weight:

[0118] 50 parts of acrylamide, 100 parts of functional monomer, 400 parts of methacryloxyethyltrimethylammonium chloride, 1 part of chain extender polyethylene glycol diacrylate, surfactant cetyltrimethyl 13 parts of ammonium bromide, 0.13 parts of initiator (0.1 part of azobisisobutylamidine hydrochloride, 0.02 part of ammonium persulfate, 0.01 part of sodium bisulfite) and 440 parts of water;

[0119] Wherein, the functional monomer is prepared by reacting 2-(chloromethyl)benzoyl chloride and N,N-dimethyltetradecylamine, and then esterifying with hydroxyethyl acrylate.

[0120] 2, a kind of preparation method of acid thickener, comprises the following steps:

[0121] (1) Preparation of functional monomers: 70 grams of dichloromethane, 38 grams of 2-(chloromethyl)benzoyl chloride and 24 grams of N,N- Dimethyltetradecylamine, after passing nitrogen to remove oxygen, raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com