Cell lysis device and cell purification and/or cell lysis method based on cell lysis device

A lysis device and cell technology, applied in cell dissociation methods, biochemical equipment and methods, methods of stress-stimulated microbial growth, etc., can solve the problems of low lysis accuracy, inability to guarantee, and inability to lysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The microtube electrode 12 is preferably prepared by the following method: using a needle pulling instrument to draw the microtube raw material tube to obtain a microtube;

[0020] Fill the two microtubes with liquid metal, centrifuge to make the liquid metal move to the tip of the microtube; cut off the microtube so that the inner diameter of the tip of the microtube is 4-20 μm. The present invention has no special limitation on the amount of liquid metal to be filled, as long as it can conduct electricity.

[0021] In the present invention, the inner diameter of the tip of the microtube is preferably 5-15 μm, more preferably 10 μm.

[0022] In the present invention, the speed of the centrifugation is preferably 3000r / min-1200r / min (corresponding to 5-15μm); the time of the centrifugation is preferably 2min; the equipment used for the centrifugation is preferably a centrifuge.

[0023] In the present invention, the device for severing the microtube is preferably a sho...

Embodiment 1

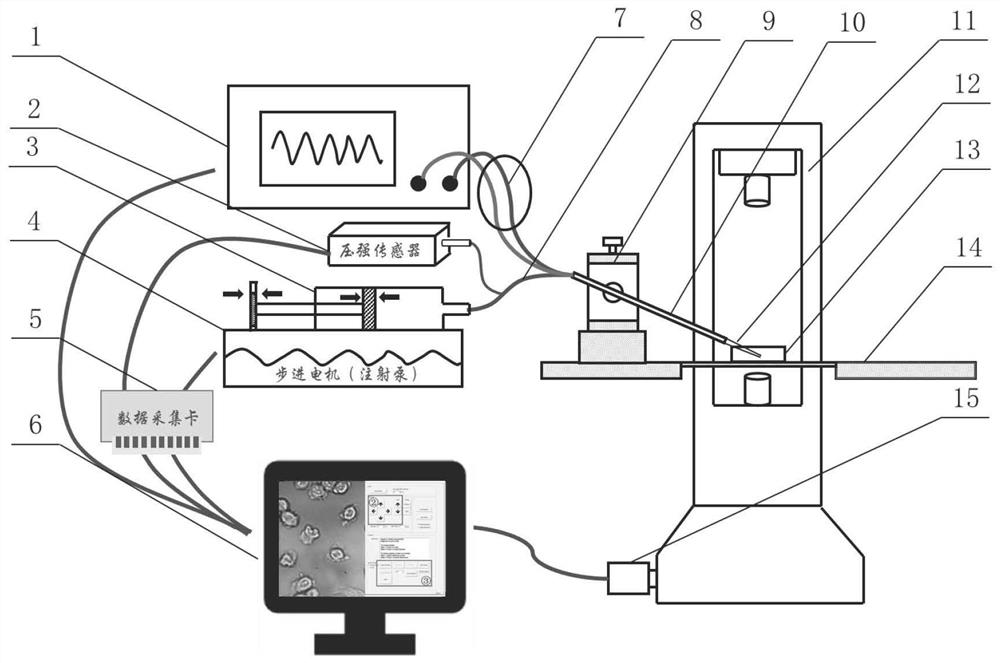

[0054] Such as figure 1 As shown, the cell lysing device of this embodiment consists of a pulse power supply 1, a pressure sensor 2, a syringe pump 3, a stepper motor 4, a data acquisition card 5, a computer 6, a copper wire 7, a microtube channel 8, a mechanical arm 9, a micro Tube frame 10, inverted microscope 11, microtube electrode 12, culture dish (cell sample) 13, mobile stage 14 and camera 15 are composed.

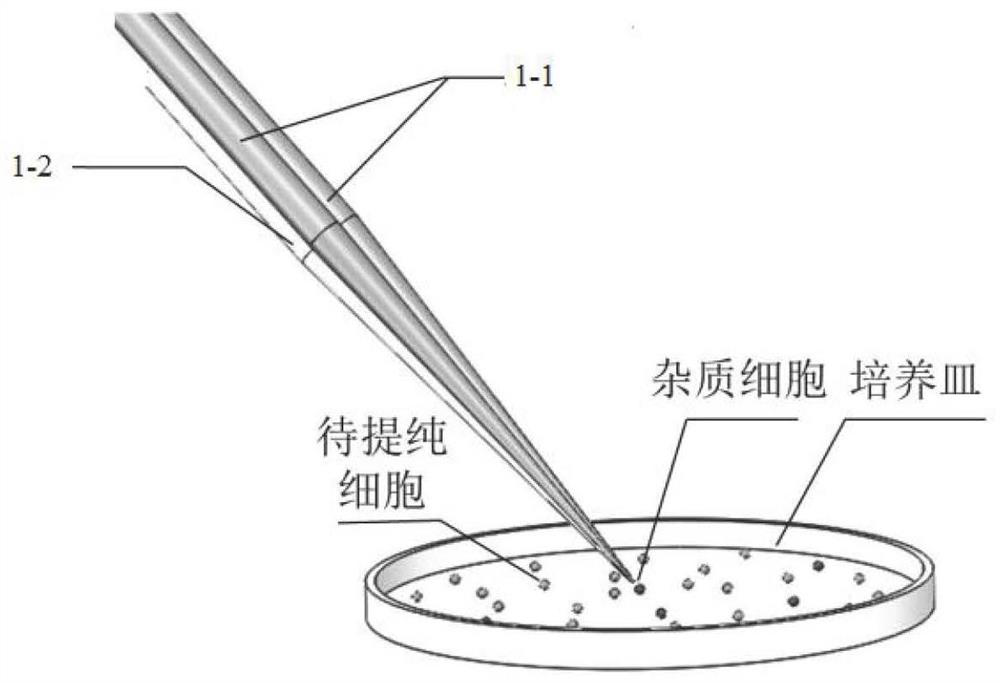

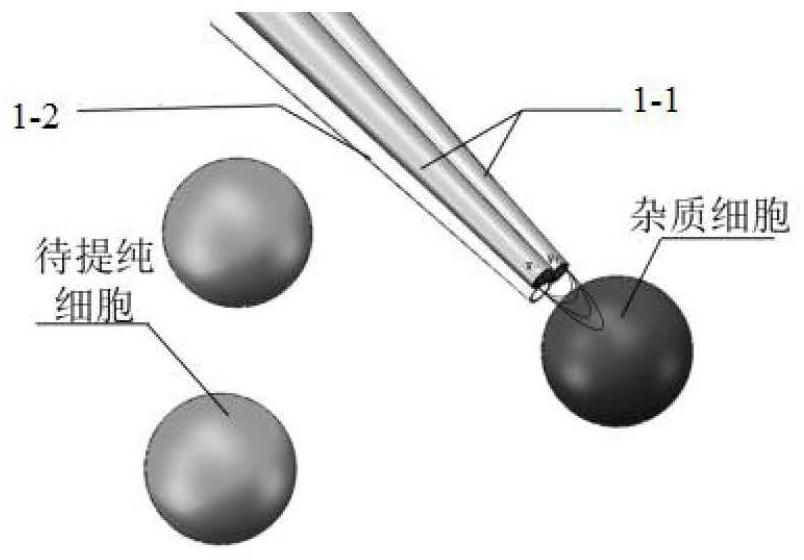

[0055] The whole system is mainly divided into two modules, namely image 3 Impurity cell lysis module, Figure 4 Cell lysate collection module. in image 3 What is realistic is a local schematic diagram of the high-voltage electric field generated by the tip of the microtube electrode during cell lysis. The microtube electrode 12 in this system is composed of three single microtubes, two of which are filled with liquid metal gallium and used as electrodes. The two electrodes are connected to the pulse power supply 1 by a copper wire 7. During lysis, the pulse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com