White copper-based antibacterial fiber and preparation method thereof

An antibacterial fiber and copper-based technology, which is applied in the field of white copper-based antibacterial fiber and its preparation, can solve the problems of different copper valence states and existing states, narrowing fiber application range, and large color difference, achieving high repeatability and widening Dyeable range, excellent effect of washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A white copper-based antibacterial fiber, composed of 0.4% nano copper-nickel alloy antibacterial agent, 99% PA6, 0.2% low molecular weight wax, 0.2% oleic acid and 0.2% antioxidant 1010. Wherein, the average particle size of the nano-copper-nickel alloy antibacterial agent is 200nm, and is coated with oleic acid and dispersed.

[0053] The preparation method of white copper-based antibacterial fiber comprises the steps:

[0054] (1) Grinding: add PA6 into a pulverizer and grind it into PA6 powder;

[0055] (2) Weighing: take by weight nano-copper-nickel alloy antibacterial agent, PA6 powder, low molecular wax, oleic acid, antioxidant 1010;

[0056] (3) Mixing: Add 0.4% nano-copper-nickel alloy antibacterial agent, 99% PA6 powder, 0.2% low-molecular wax, 0.2% oleic acid and 0.2% antioxidant 1010 into a high-speed mixer for high-low speed Mixing, wherein the low-speed mixing speed is 700 rpm, the mixing time is 2 minutes, the high-speed mixing speed is 1400 rpm, and th...

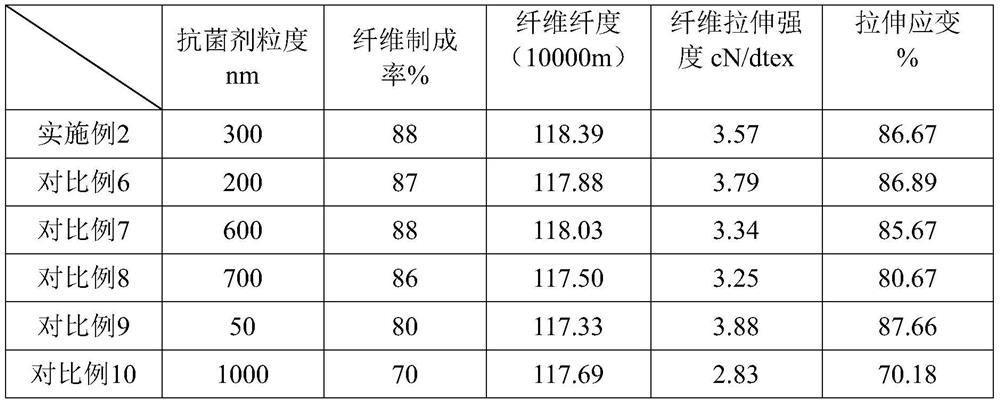

Embodiment 2

[0063] A white copper-based antibacterial fiber, composed of 1% nano-iron-copper-nickel alloy antibacterial agent, 98.1% PA6, 0.3% silane coupling agent KH560, 0.3% fatty acid and 0.3% antioxidant 1098, wherein, The nano-iron-copper-nickel alloy antibacterial agent has an average particle diameter of 300nm, and is subjected to dispersion treatment coated with fatty acid.

[0064] The preparation method of white copper-based antibacterial fiber is the same as in Example 1.

Embodiment 3

[0066] A white copper-based antibacterial fiber, composed of 3% nano-zinc-copper-nickel alloy antibacterial agent, 95.5% PA66, 0.5% phthalate coupling agent, 0.5% ascorbic acid and 0.5% antioxidant 168, of which , The average particle size of the nano-zinc-copper-nickel alloy antibacterial agent is 600nm, and it has been coated with ascorbic acid and dispersed.

[0067] The preparation method of white copper-based antibacterial fiber is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com