Bag dust removal ash separation process

A bag dust removal and ash removal technology, applied in the field of mineral processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

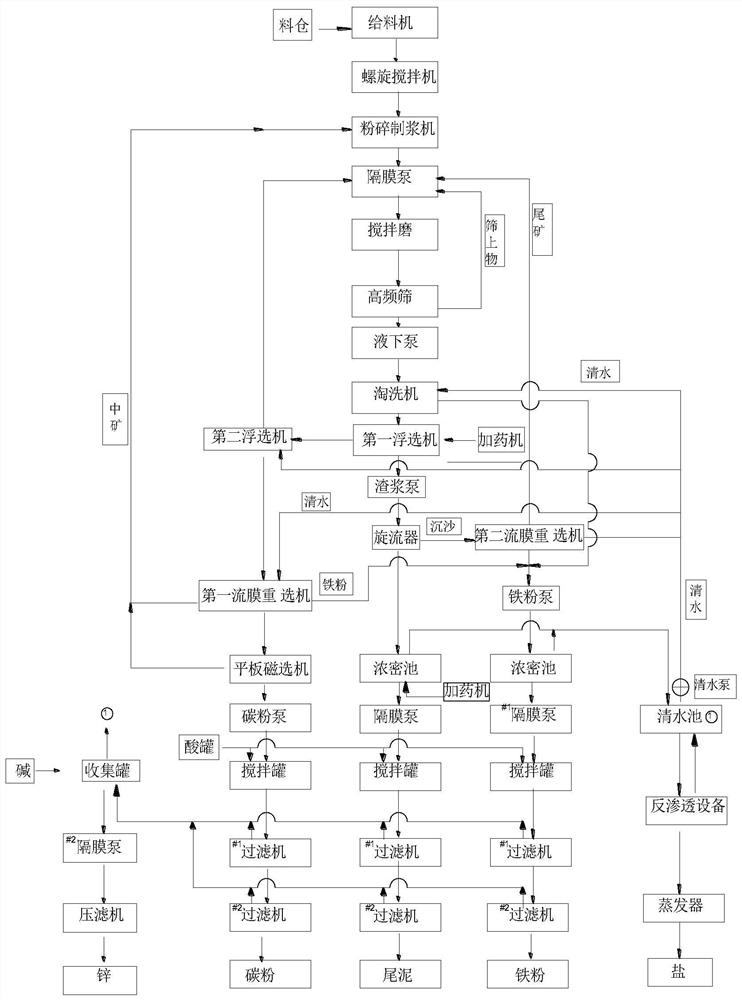

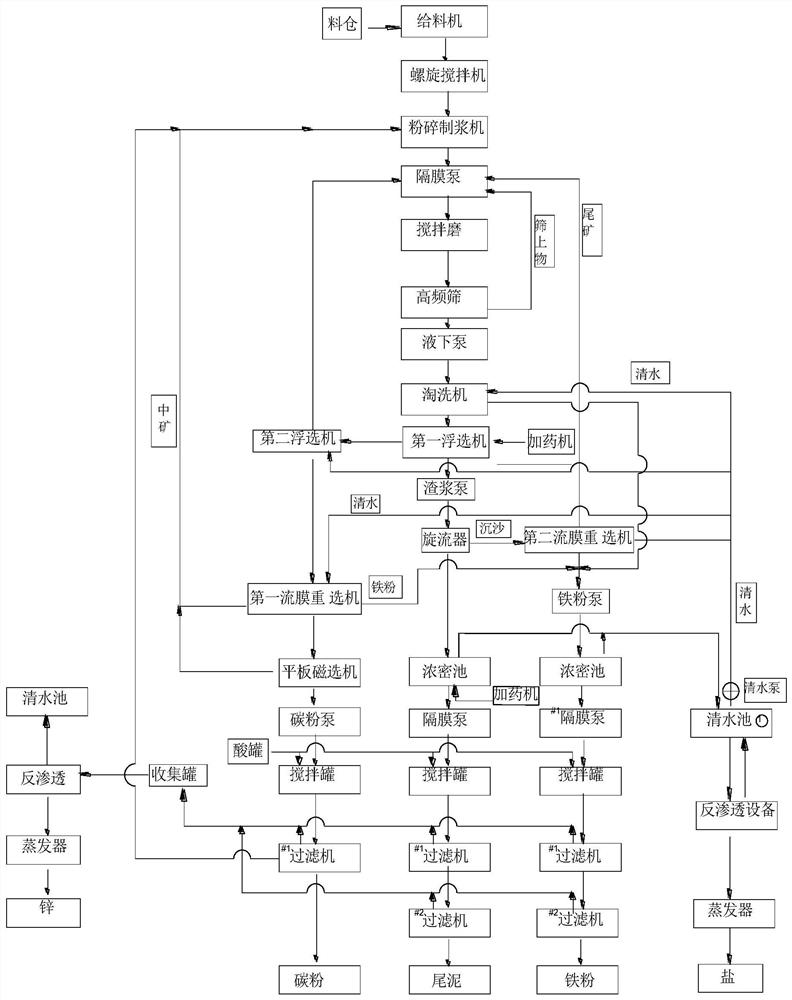

[0035] Such as figure 1 As shown, this example proposes

[0036] The bag dust removal ash separation process includes the following steps:

[0037] Step A, the raw materials are unloaded by the transport vehicle into the screw mixing conveyor equipped with spray water and transported to the raw material yard for stacking. Water is added to the raw materials to prevent dust. Add water into the spiral mixer and stir into a fluid state,

[0038] Step B, the fluid material enters the crushing pulper, adds water and grinds it, and flows to the high frequency sieve by the diaphragm pump through the stirring mill.

[0039] Step C, the material on the high-frequency sieve is returned to the diaphragm pump for grinding, and step B is repeated, the under-screen material of the high-frequency sieve is pumped by the submerged pump into the elutriation machine for sorting, and the clear water tank is used for elutriation during the elutriation process The machine provides clean water, ...

Embodiment 2

[0052] Such as figure 1 As shown, based on the same idea as the above-mentioned embodiment 1, on the basis of embodiment 1, a process of centralized recovery of filtrate is also proposed.

[0053] On the basis of embodiment 1, step J is also included,

[0054] Filtrate recycling and sorting of zinc products, in step E, step G and step H, the acid-containing filtrate flowing out of the vacuum belt filter is pumped into the collection tank by the sewage pump, and alkali is added for neutralization, and the precipitate is pulverized to produce The pulp machine is fed into the filter press for dehydration to obtain zinc-containing products.

[0055] In this embodiment, in the recycling process of carbon powder, iron powder and tailings cake, zinc products can be further sorted, and the filtrate of the vacuum belt filter can be collected at the same time, so as to prevent random discharge of sewage and reduce environmental pollution.

[0056] Further, in step E, step G and step H...

Embodiment 3

[0058] Such as figure 1 As shown, based on the same concept as the above-mentioned embodiment 2, the dehydration filtrate is further recycled on the basis of embodiment 2.

[0059] specific,

[0060] In step J, the filtrate after dehydration by the filter press flows into the thickening tank in step H for recycling.

[0061] In step H, the clear water from the upper part of the dense pool flows to the clear water pool for recycling and reuse.

[0062] In this embodiment, the recycling rate of clear water can be improved, and the output of tailings in the subsequent steps of thick bottom flow concentration in step H and the output of zinc products after the filtrate is recovered after the tailings flow into the vacuum belt filter can also be recycled. Sorting to increase the output of each product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com