Fe3O4/mesoporous graphitized carbon compound as well as preparation method and application thereof

A graphitized carbon and composite technology, applied in the direction of graphene, ferrous oxide, iron oxide/iron hydroxide, etc., can solve the problems of limited catalytic activity, reduced exposed surface area, easy agglomeration, etc., and achieve stability The effects of spatial structure, good peroxidase-like activity, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

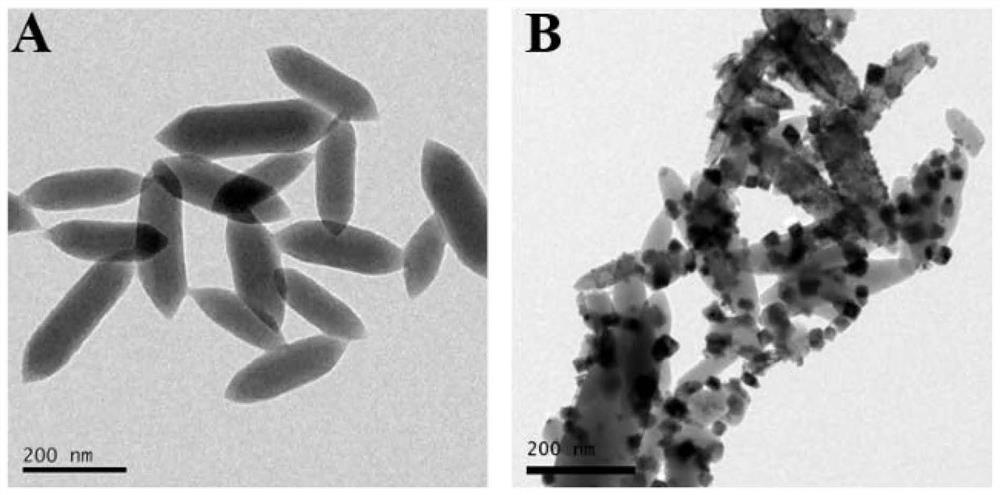

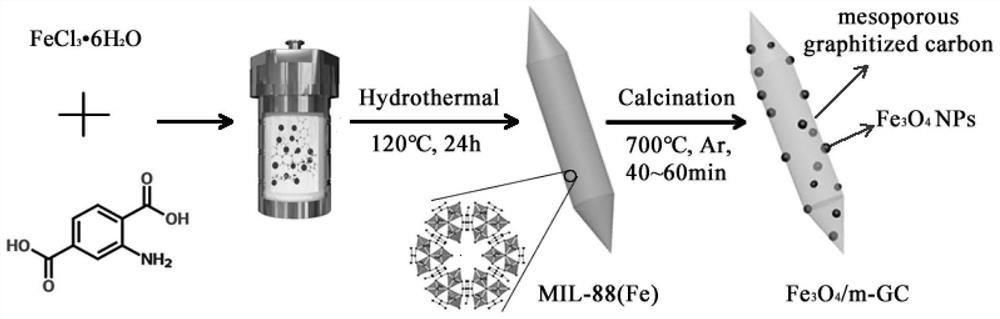

[0046] 1. Synthesis of Fe-MOF materials

[0047] The Fe-MOF material was synthesized by the hydrothermal method as a precursor, 50mL of ultrapure water was added as a reaction solvent into the liner of a high-pressure polytetrafluoroethylene reactor, 1.40-1.60g of ferric chloride hexahydrate was added as a source of metal salt, and 0.12 ~0.16g of 2-aminoterephthalic acid is used as an organic ligand to chelate the metal salt center, and the mixed solution is stirred with a magnetic stirrer at room temperature for 1 to 2 hours. Add 0.60-0.80g of Pluronic F127, Pluronic F127 is a non-ionic surfactant, which can promote the solubility of non-water-soluble raw materials in solvents. Then add 0.6-0.8mL acetic acid solution, because acetic acid has a carboxyl structure, it can compete with 2-aminoterephthalic acid to bind metal salts, and can play a role in modulating the crystallization process and material particle size. The above mixed solution was stirred with a magnetic stirre...

Embodiment 2

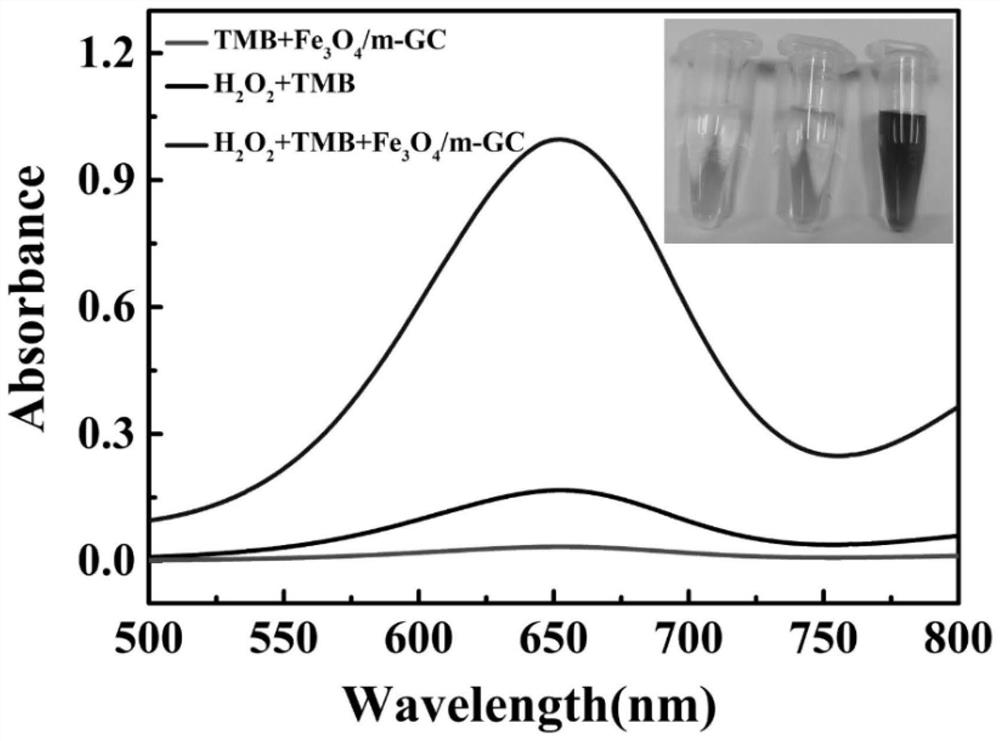

[0055] Will Fe 3 o 4 / Mesoporous graphitized carbon composites as peroxidase-like biosensors:

[0056] 1. Fe 3 o 4 / Mesoporous graphitized carbon composite is used as a peroxidase-like cascade colorimetric biosensor to detect glucose, and the specific steps are as follows:

[0057] (a) dissolving glucose in a phosphate buffer solution with a concentration of 10 mM and pH=7.0 to prepare glucose solutions of different concentrations;

[0058] (b) adding 40 μL of glucose oxidase with a concentration of 0.2 mg / mL to 360 μL of glucose solutions of different concentrations prepared in step (a) to obtain solution A;

[0059] (c) Add 550 μL of NaAc-HAc buffer solution with a concentration of 0.2M and pH=4, 40 μL of TMB solution with a concentration of 1 mM and 10 μL of Fe with a concentration of 1 mg / mL to solution A in (b). 3 o 4 / Mesoporous graphitized carbon solution to form a mixed solution; after incubation at 45°C for 20 minutes, it is used for the determination of the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com