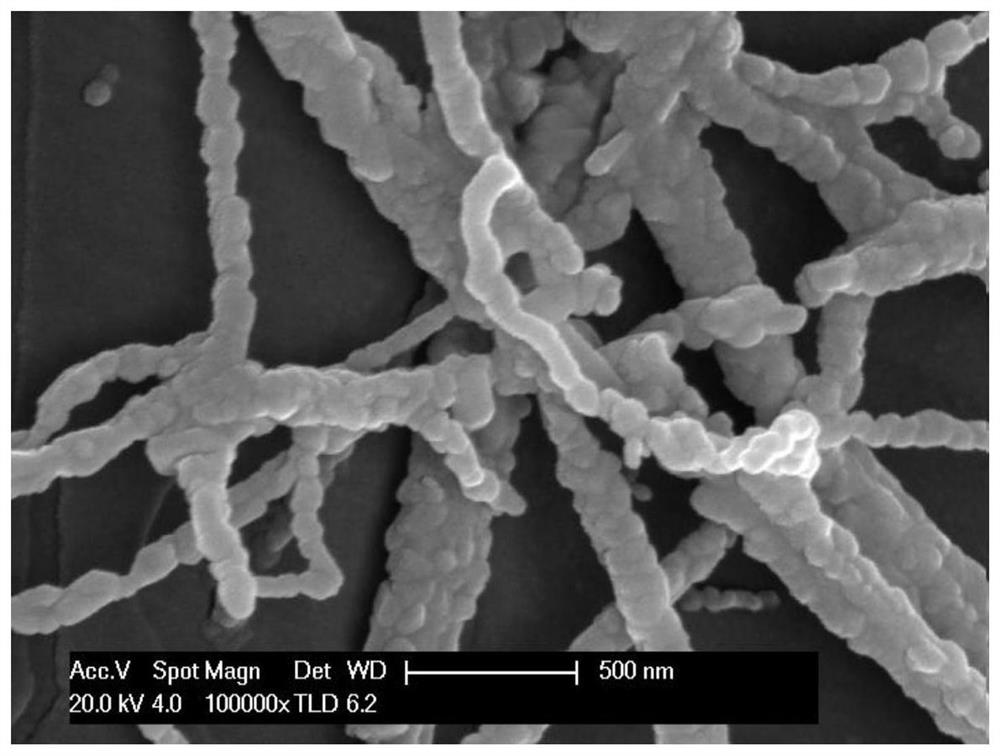

Preparation method and application of high-purity silver-doped bismuth tungstate nano-antibacterial fibrous membrane

A nano-antibacterial fiber and nano-fiber technology are applied in the field of preparation of high-purity silver-doped bismuth tungstate nano-antibacterial fiber film, which can solve the problems of difficulty in recycling and reuse, easy agglomeration of nanoparticles, and improve the probability of electronic transition. , high antibacterial efficiency, the effect of improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 2.52g citric acid in 7mL deionized water, add nitric acid to adjust the pH value to 2, 3, 4, then add 0.002mol Bi(NO 3 ) 3 ·5H 2 O, stirred and dissolved with a magnetic stirrer at room temperature. At the same time, 0.001mol of Na 2 WO 4 2H 2 O was dissolved in 10 mL of deionized water. Then, the sodium tungstate solution was slowly added dropwise to the bismuth nitrate solution, magnetically stirred, and 0.1mol / L AgNO was added dropwise under stirring. 3 The solution is such that the mass fraction of silver ions in bismuth tungstate is 2%, which is recorded as solution 1. Take 1.3g K-90 polyvinylpyrrolidone and dissolve it in 10mL ethanol, and keep stirring to dissolve. Take 3mL of solution 1 and add it to the polyvinylpyrrolidone-ethanol solution, and keep stirring for 12h to fully mix. A uniform and stable spinning precursor solution was obtained. Fill it into a 10mL syringe. The syringe is on the positive pole, and its injection port is a 0.7mm n...

Embodiment 2

[0024] Dissolve 2.52g citric acid in 7mL distilled water, add 3mL nitric acid, then add 0.002mol Bi(NO 3 ) 3 ·5H 2 O, stirred and dissolved with a magnetic stirrer at room temperature. At the same time, 0.001mol of Na 2 WO 4 2H 2 O was dissolved in 10 mL of deionized water. Then, the sodium tungstate solution was slowly added dropwise to the bismuth nitrate solution, magnetically stirred, and 0.1mol / L AgNO was added dropwise under stirring. 3 The solution makes the mass fraction of silver ions in bismuth tungstate 1%, 2%, and 3%, which is recorded as solution 1. Dissolve 1.3g of K-90 polyvinylpyrrolidone in 10mL of ethanol and keep stirring until dissolved. Take 3mL of solution 1 and add it into the polyvinylpyrrolidone-ethanol solution, and keep stirring for 12h to mix thoroughly. A uniform and stable electrospun sol was obtained. Put the electrospun sol into a syringe with a volume of 10mL. The syringe is at the positive pole, and its injection port is a 0.7mm needl...

Embodiment 3

[0026] Dissolve 2.52g of citric acid in 7mL of deionized water, add 3mL of nitric acid, and then add 0.002mol Bi(NO 3 ) 3 ·5H 2 O, stirred and dissolved with a magnetic stirrer at room temperature. At the same time, 0.001mol of Na 2 WO 4 2H 2O was dissolved in 10 mL of deionized water. Then, the sodium tungstate solution was slowly added dropwise to the bismuth nitrate solution, magnetically stirred, and 0.1mol / L AgNO was added dropwise under stirring. 3 The solution is such that the mass fraction of silver ions in bismuth tungstate is 2%, which is recorded as solution 1. Take 1.2g, 1.3g, 1.4g of K-90 polyvinylpyrrolidone and dissolve in 10mL of ethanol, and keep stirring to dissolve. Take 3mL of solution 1 and add it to the polyvinylpyrrolidone-ethanol solution, and keep stirring for 12h to fully mix. A uniform and stable spinning precursor solution was obtained. Fill it into a 10mL syringe. The syringe is on the positive pole, and its injection port is a 0.7mm need...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap