Water-blocking sealant and preparation method thereof

A sealant and water-blocking technology, which is applied in the field of sealants, can solve the problems such as the decrease of the joint strength of the sealant and poor waterproof effect, and achieve the effects of increasing the use time, firm bonding, and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

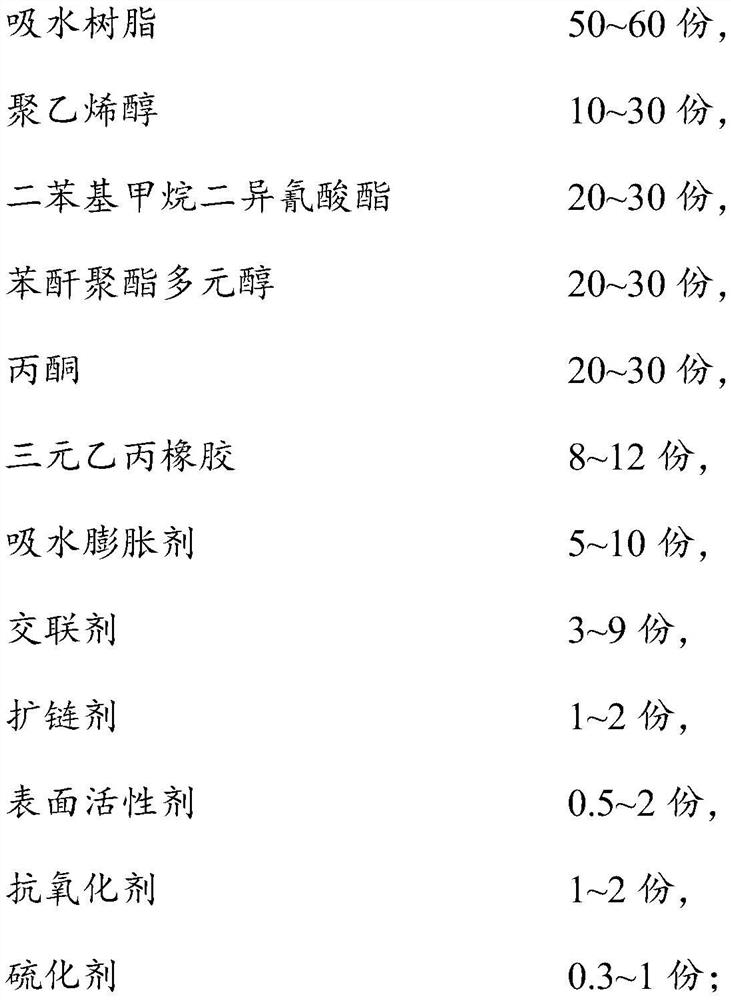

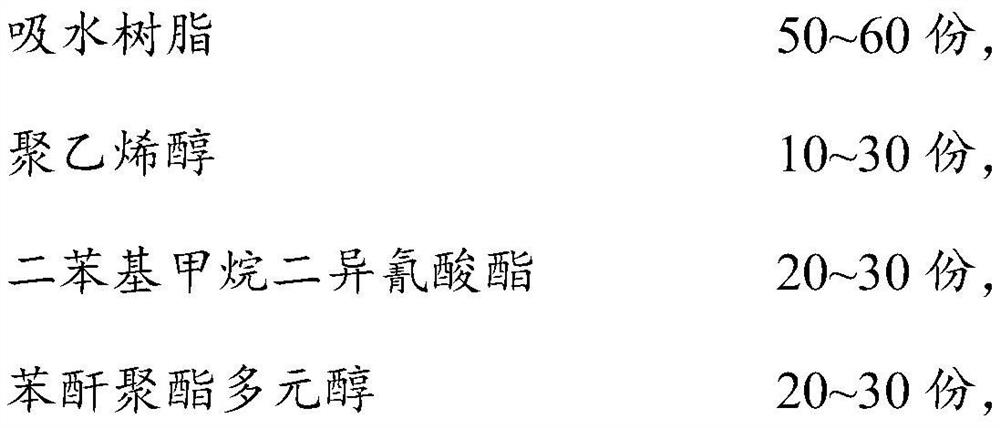

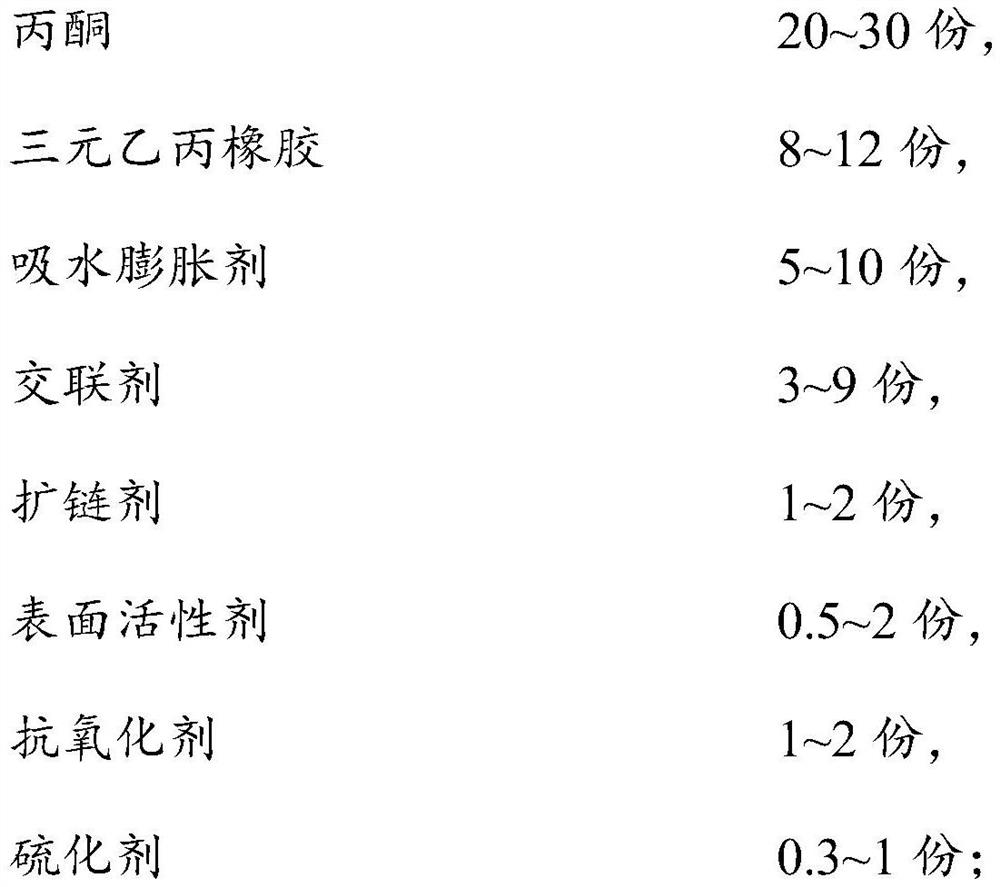

[0030] A water-blocking sealant, comprising the following raw materials in parts by mass: 50 parts of water-absorbent resin, 10 parts of polyvinyl alcohol, 20 parts of diphenylmethane diisocyanate, 20 parts of phthalic anhydride polyester polyol, 20 parts of acetone, terpolymer 8 parts of propylene rubber, 5 parts of water-absorbing swelling agent, 3 parts of crosslinking agent, 1 part of chain extender, 0.5 part of surfactant, 1 part of antioxidant, 0.3 part of vulcanizing agent;

[0031] The water-absorbing resin is a mixture of polyacrylic acid sodium salt and polyacrylamide according to the mass ratio of polyacrylic acid sodium salt:polyacrylamide=1:2;

[0032] The water-absorbing swelling agent is a mixture of white carbon black and bentonite according to the mass ratio of white carbon black:bentonite=1:1;

[0033] The vulcanizing agent is sulfur;

[0034] The chain extender is ethylene glycol;

[0035] The crosslinking agent is vinyltriethoxysilane;

[0036] The surfa...

Embodiment 2

[0043] A water-blocking sealant, comprising the following raw materials in parts by mass: 60 parts of water-absorbent resin, 30 parts of polyvinyl alcohol, 30 parts of diphenylmethane diisocyanate, 30 parts of phthalic anhydride polyester polyol, 30 parts of acetone, terpolymer 12 parts of propylene rubber, 10 parts of water-absorbing swelling agent, 9 parts of crosslinking agent, 2 parts of chain extender, 2 parts of surfactant, 2 parts of antioxidant, 1 part of vulcanizing agent;

[0044] The water-absorbing resin is a mixture of polyacrylic acid sodium salt and polyacrylamide according to the mass ratio of polyacrylic acid sodium salt:polyacrylamide=1:2;

[0045] The water-absorbing swelling agent is a mixture of white carbon black and bentonite according to the mass ratio of white carbon black:bentonite=1:1;

[0046] Described vulcanizing agent is sulfur monochloride;

[0047] The chain extender is ethylene glycol and glycerol;

[0048] Described linking agent is glycerol;...

Embodiment 3

[0056] A water-blocking sealant, comprising the following raw materials in parts by mass: 55 parts of water-absorbing resin, 20 parts of polyvinyl alcohol, 25 parts of diphenylmethane diisocyanate, 25 parts of phthalic anhydride polyester polyol, 25 parts of acetone, terpolymer 10 parts of propylene rubber, 8 parts of water-absorbing swelling agent, 6 parts of crosslinking agent, 1.5 parts of chain extender, 1 part of surfactant, 1.5 parts of antioxidant, 0.6 part of vulcanizing agent;

[0057] The water-absorbing resin is a mixture of polyacrylic acid sodium salt and polyacrylamide according to the mass ratio of polyacrylic acid sodium salt:polyacrylamide=1:2;

[0058] The water-absorbing swelling agent is a mixture of white carbon black and bentonite according to the mass ratio of white carbon black:bentonite=1:1;

[0059] The vulcanizing agent is tetramethylthiuram disulfide;

[0060] The chain extender is ethylene glycol, glycerin and ethylenediamine;

[0061] The crossl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com