Copper-aluminum film electrode for enzyme-free glucose sensor and its preparation method and application

A technology of glucose sensor and thin film electrode, applied in the direction of instruments, scientific instruments, material electrochemical variables, etc., can solve the problems of poor particle uniformity, strong uncontrollability, complex operation, etc., to reduce detection limit, improve sensitivity and linearity , the effect of shortening the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

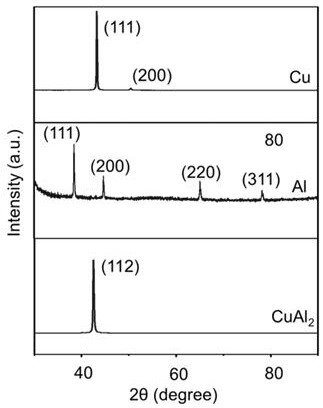

[0054] Start the main power of the magnetron sputtering apparatus and turn on the cooling water. After the pressure in the sputtering chamber is balanced with the atmospheric pressure, manually adjust the target base distance to a reasonable value and fix the clean silicon wafer on the sample stage. Install the Cu target on the target position of the DC power supply, install the Al target on the target position of the RF power supply, close the door of the sputtering chamber, seal the sputtering chamber, and then evacuate the sputtering chamber. First turn on the mechanical pump and side pumping valve, evacuate to below 0.1Pa, then turn off the mechanical pump and side pumping valve. Then turn on the molecular pump, fore valve and gate valve in turn until the vacuum degree reaches 5Í10 -4 After Pa is below, open the inlet valve, set the flow rate of argon gas to 40 sccm, and then pass argon gas into the sputtering chamber. Adjust the gate valve so that the coating pressure is...

Embodiment 2

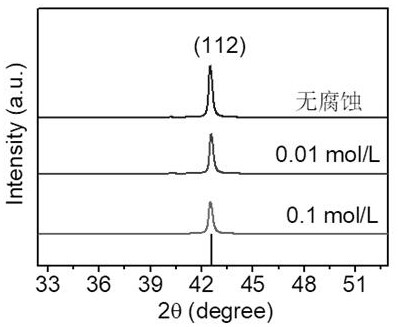

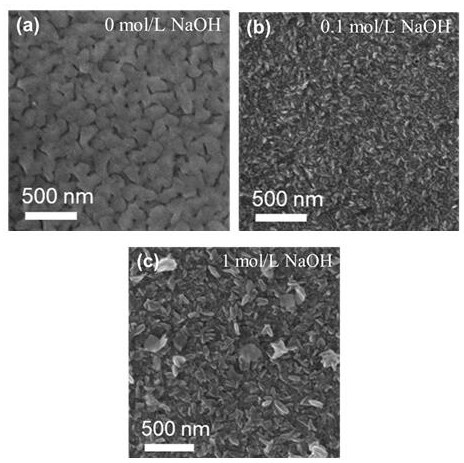

[0058] The CuAl prepared by embodiment 1 2 The intermetallic compound was placed in 0.01mol / L NaOH solution, and the CuAl 2 The intermetallic compound is electrochemically corroded, the voltage of the electrochemical corrosion is 0.5V, and the corrosion time is 450s. During the voltage corrosion process, the Al on the surface is consumed by reactive corrosion in NaOH solution. Thus, a copper-aluminum thin film electrode is obtained.

Embodiment 3

[0060] The CuAl prepared by embodiment 1 2 The intermetallic compound was placed in 0.1mol / L NaOH solution, and the CuAl 2 The intermetallic compound is electrochemically corroded, the voltage of the electrochemical corrosion is 0.5V, and the corrosion time is 450s. During the voltage corrosion process, the Al on the surface is consumed by reactive corrosion in NaOH solution. Thus, a copper-aluminum thin film electrode is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com