Composite herbicide containing pyroxasulfone

A technology of compound herbicide, pyraclofenazole, which is applied in the field of pesticides, can solve the problems of weed resistance and other problems, achieve the effects of reducing phytotoxicity, improving the effect of compound weed control and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Modified dispersants are made by the following steps:

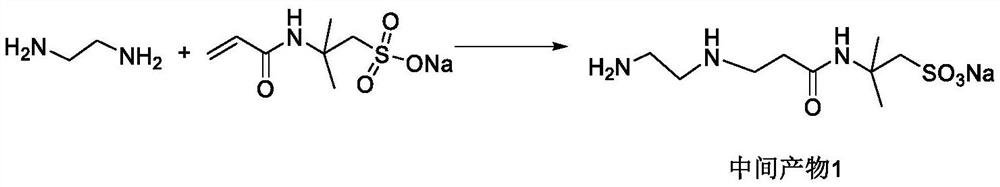

[0044]Step A. Add ethylenediamine and glacial acetic acid into a three-necked flask, stir until the ethylenediamine is completely dissolved, then add 2,2-acrylamido-2-methylpropanesulfonate dropwise, and use tin foil to protect it from light. Under nitrogen protection, the temperature of the reaction system was heated to 77°C with an oil bath, refluxed for 6 hours, and then glacial acetic acid and unreacted small molecules were removed by rotary evaporation under reduced pressure at 45°C to obtain intermediate product 1;

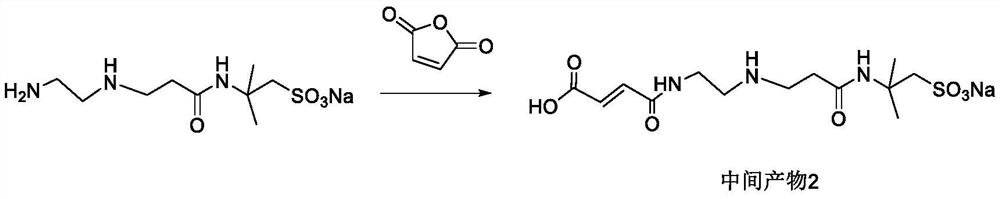

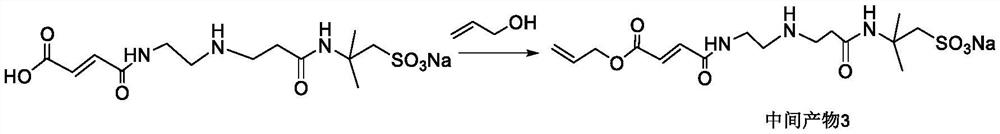

[0045] Step B, add the intermediate product 1, maleic anhydride, and glacial acetic acid obtained in step A into a three-necked flask in sequence, and after stirring evenly, heat the temperature of the reaction system to 75° C. with an oil bath, reflux for 12 hours, and then The reaction solution was rotary evaporated under reduced pressure at 35°C to remove glacial acetic acid and unreacted smal...

Embodiment 2

[0052] The modified dispersant is made through the following steps: with reference to each step in Example 1;

[0053] The amount of raw materials used in each step is shown in Table 2.

[0054] Table 2

[0055]

Embodiment 3

[0057] The adsorbent is modified mesoporous silica and is made by the following steps:

[0058] Step 1. Add cetyltrimethylammonium bromide to the ethanol solution, then stir at room temperature until the cetyltrimethylammonium bromide is completely dissolved, then add ethyl orthosilicate and diethanolamine in sequence, Stir the reaction for 30 hours, centrifuge the product at 5500r / min for 15 minutes, wash it with absolute ethanol three times, dry it in a drying oven for 12 hours, transfer it to a muffle furnace for calcination at a high temperature of 580°C for 7 hours, and obtain mesoporous silica;

[0059] Step 2: Add the mesoporous silica obtained in Step 1 into the ethanol solution, ultrasonically disperse for 45 minutes, then add epoxybutyltrimethoxysilane, stir and react at 63°C for 16 hours, then wash and filter with deionized water, Then, it was dried in a drying oven at 25° C. for 8 hours to obtain modified mesoporous silica.

[0060] The amount of raw materials use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com