Graphene composite ammonia-hydrogen conversion catalyst and preparation method thereof

A graphene composite and composite material technology, applied in the field of ammonia-hydrogen conversion, can solve the problems of lack of structural stabilizers, achieve high decomposition activity, improve catalytic activity, and reduce economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

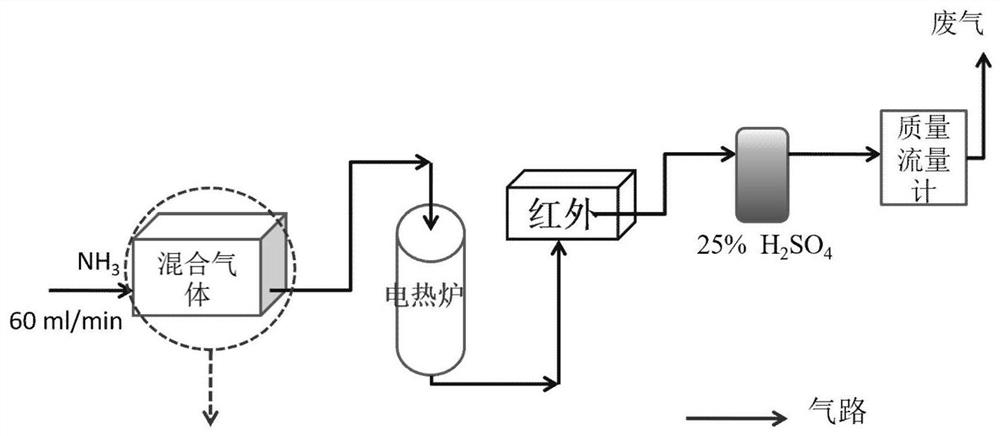

[0042] see figure 1 , a kind of preparation method of graphene composite material ammonia-hydrogen conversion catalyst, comprises the following steps:

[0043] (1) In the temperature range of 100-500 ° C, heat graphene, metal oxides and metal hydrides in a gas atmosphere filled with nitrogen or argon for 72 hours to 120 hours, and replace the oxides with hydride ions Partial oxygen ion, the molar ratio of described graphene, metal oxide and metal hydride is (0.1-1): (1-1.2): (3-3.5), obtains the graphite of vacuum drying after removing unnecessary metal oxide Alkene composite oxyhydride powder;

[0044] One way to remove excess metal oxides is to use NH 4 Cl / methanol (0.1 mol / 300 mL) was used to remove excess metal oxides. Thanks to NH 4 Cl is a weak acid that helps remove various impurities during the washing process.

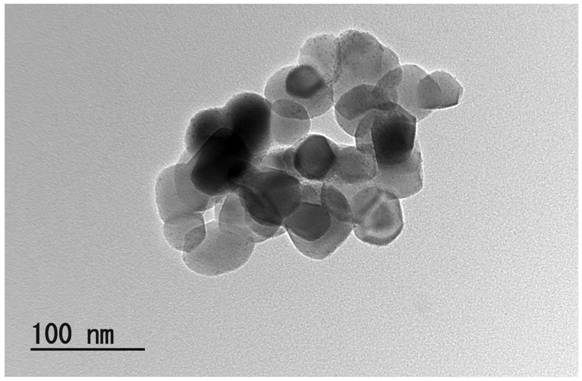

[0045] The graphene adopts the powder whose particle diameter is distributed in the range of 100 nanometers to 200 nanometers.

[0046] The metal oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com