MEMS pressure sensor based on phase detection principle and preparation method thereof

A pressure sensor and phase detection technology, which is used in fluid pressure measurement, force measurement, piezoelectric device/electrostrictive device, etc. using capacitance change. Advanced problems, to achieve the effect of saving chip area, low price, and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

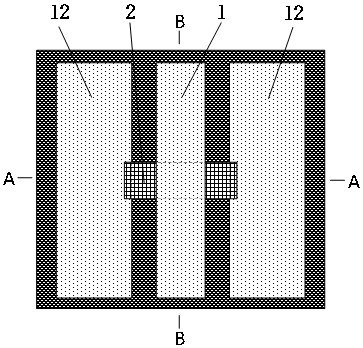

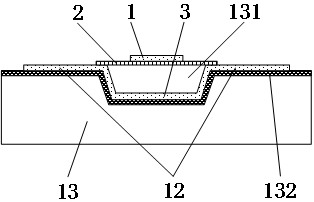

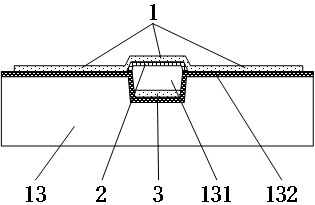

[0031] This embodiment provides a MEMS pressure sensor based on the principle of phase detection, such as Figure 1 ~ Figure 3 As shown, it includes: CPW transmission line, substrate 13, groove 131, buffer medium layer 132, MEMS film 2 and MEMS beam 3; the CPW transmission line is arranged on the substrate 13, and the substrate 13 is provided with concave Groove 131, the MEMS beam 3 is arranged in the groove 131; the MEMS film 2 and the groove 131 form a closed cavity, and the substrate 13 is made of high-resistance silicon with a resistivity greater than 1 kΩ·cm.

[0032] The CPW transmission line includes a CPW signal line 1 located in the middle of the substrate 13 and two CPW ground lines 12 located on both sides of the CPW signal line 1, the CPW signal line 1 and the CPW ground line 12 parallel to each other.

[0033] The groove 131 is located directly below the middle portion of the CPW signal line 1 . The groove 131 is a U-shaped groove, and the axis of the groove 131...

Embodiment 2

[0038] The present invention also provides the preparation method of the above MEMS pressure sensor based on the phase detection principle, such as Figure 5-11 shown, including the following steps:

[0039] S10 prepares the Si substrate 13, the substrate is for example made of high-resistance silicon, its resistivity is greater than 1kΩ·cm, and a groove 131 is etched on the substrate, the depth of the groove is for example 1-50 μm, and then A layer of buffer dielectric layer 132 is grown on the substrate by thermal oxidation, such as Figure 6 shown.

[0040] S20 sequentially pass photolithography, evaporation, and stripping on the buffer medium layer to obtain MEMS beams and CPW ground wires; as Figure 7 As shown; wherein, the MEMS beam 3 and the CPW ground wire 12 are prepared from the same material in the same process step, and are connected to each other.

[0041] S30 deposits and photoetches the PSG sacrificial layer, retains the PSG sacrificial layer inside the groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com