Intensive garden type sewage treatment system and treatment process

A sewage treatment system and water treatment technology, applied in water/sewage treatment, multi-stage water/sewage treatment, special compound water treatment, etc., can solve problems such as disordered pipelines, poor aesthetics, and insufficient advantages of intensification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

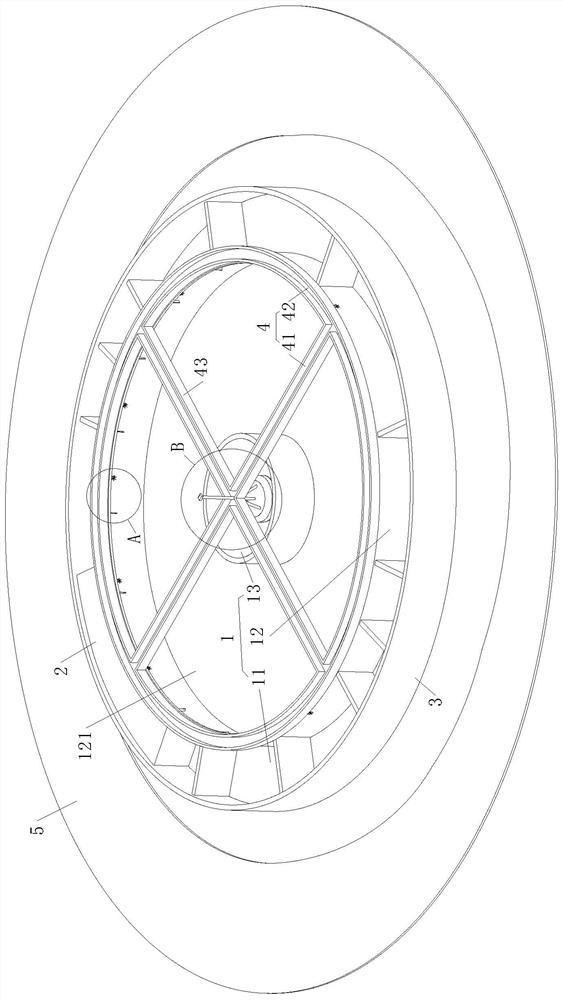

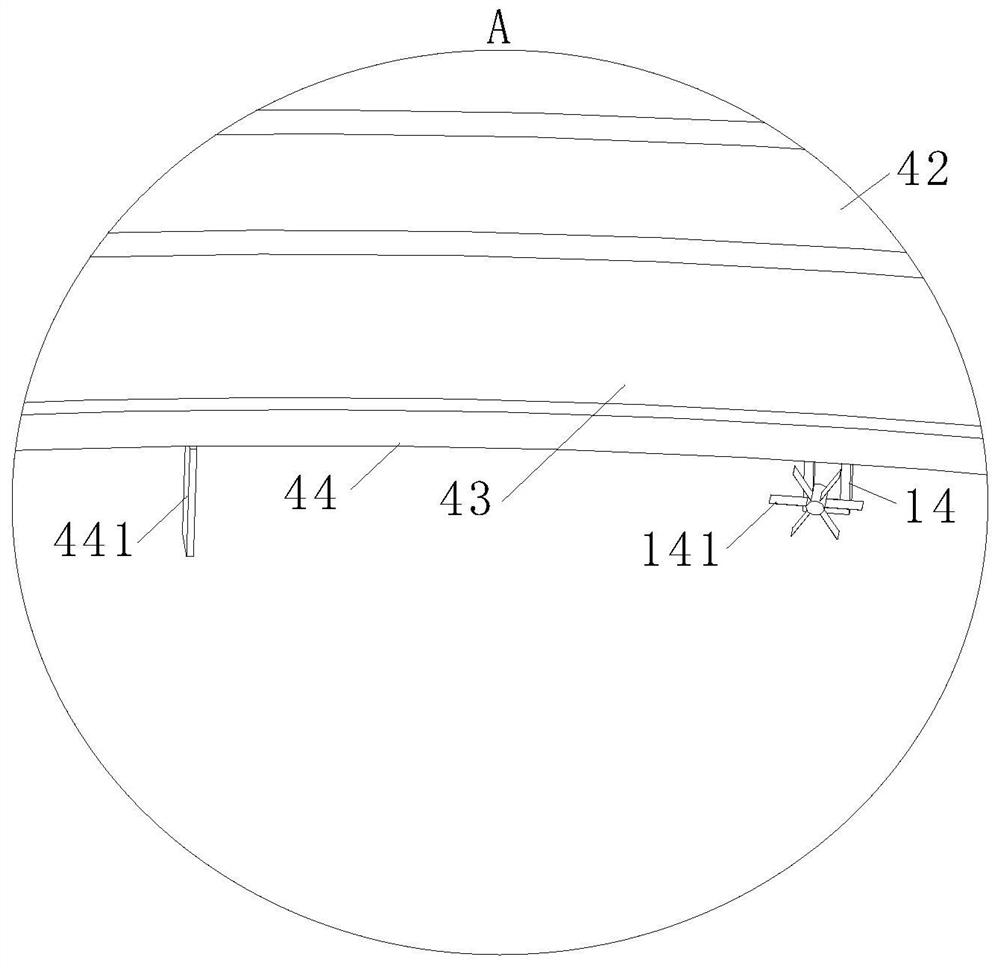

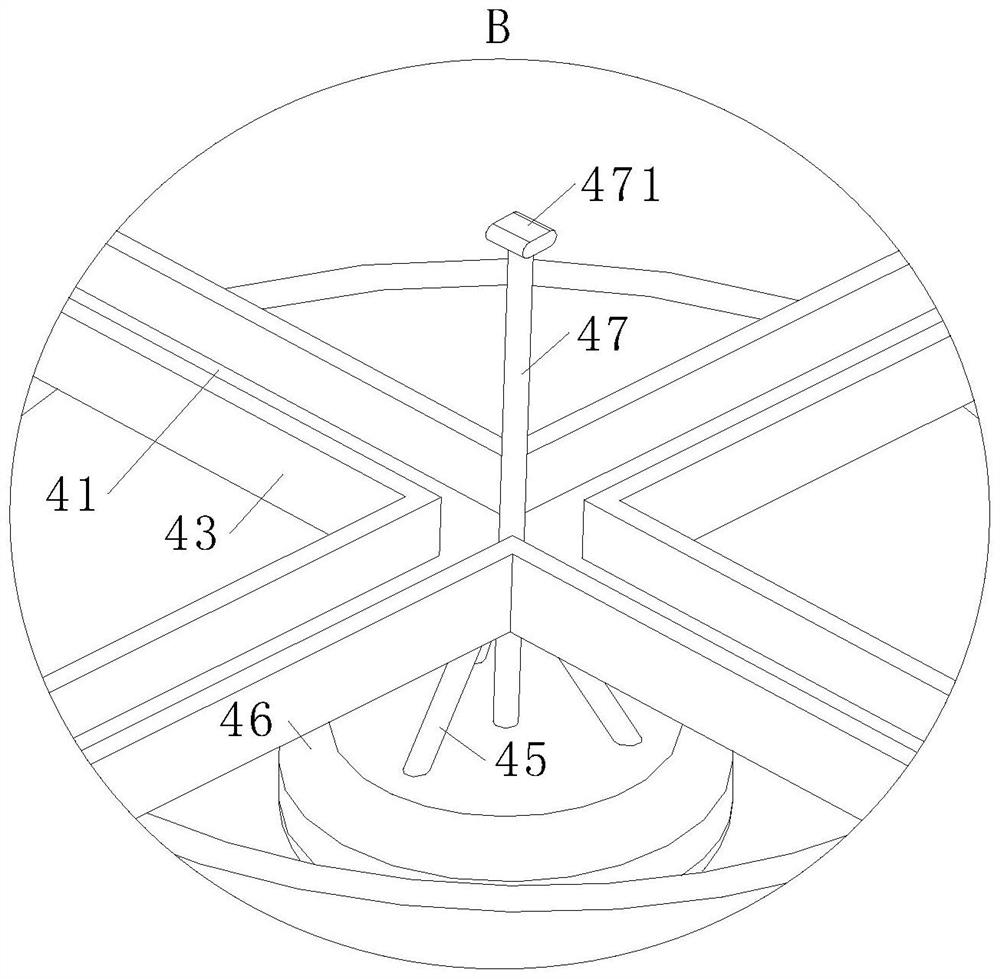

[0036] As an embodiment of the present invention, the water treatment pool area 1 also includes a pretreatment pool 11, a biochemical treatment pool 12, and an advanced treatment pool 13 connected in sequence; the equipment room 2 includes a pharmacy room, a fan room and the central control room; the biochemical treatment pool 12 also includes a micro-exposure area 121, and the water treatment pool area 1 to which the micro-exposure area 121 belongs is circularly distributed in the combined pool 3; when the water treatment system is in operation, the sewage is pretreated The grille pool, sump pool, solid-liquid separation platform, sludge pool and adjustment pool connected in sequence in the pool 11 separate the mixed solid particles in the sewage, and then make the preliminary filtered sewage flow to the sequentially connected in the biochemical treatment pool 12. Inlet area, stripping area, micro-exposure area 121 and sedimentation effluent area, the water treatment tank area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com