Synthesis method of sodium picosulfate

A technology of sodium picosulfate and a synthetic method, which is applied in the field of drug preparation, can solve problems such as difficult acquisition of raw materials, complex operation of the synthetic method, and unsuitability for industrial production, and achieve shortened reaction time, high yield, and easy control of the reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

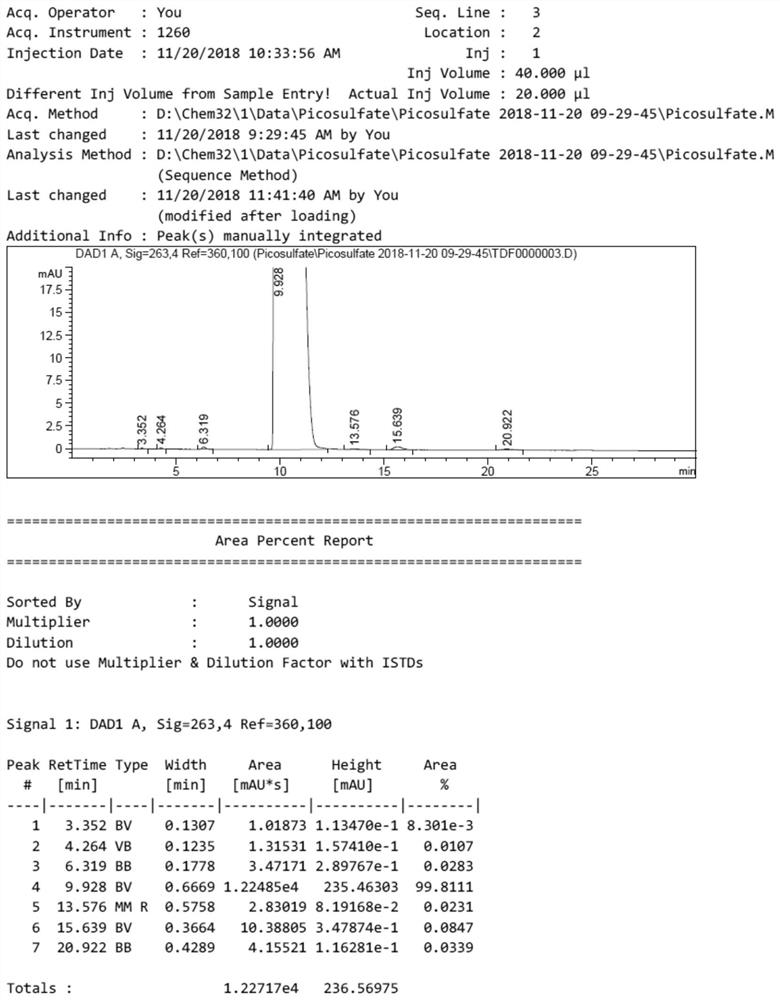

Image

Examples

Embodiment 1

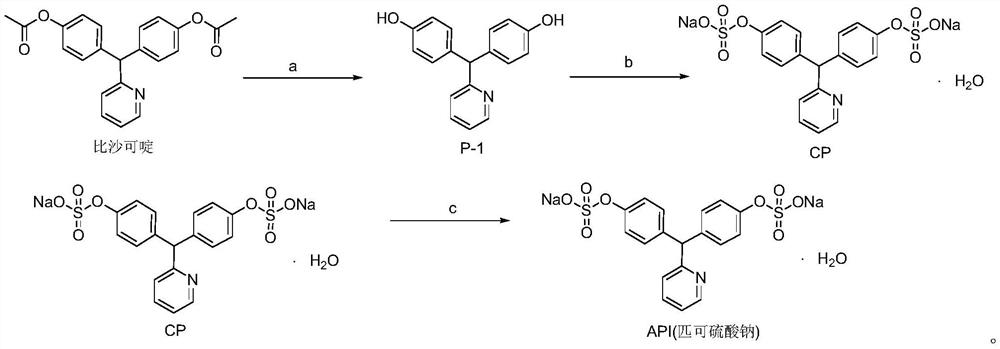

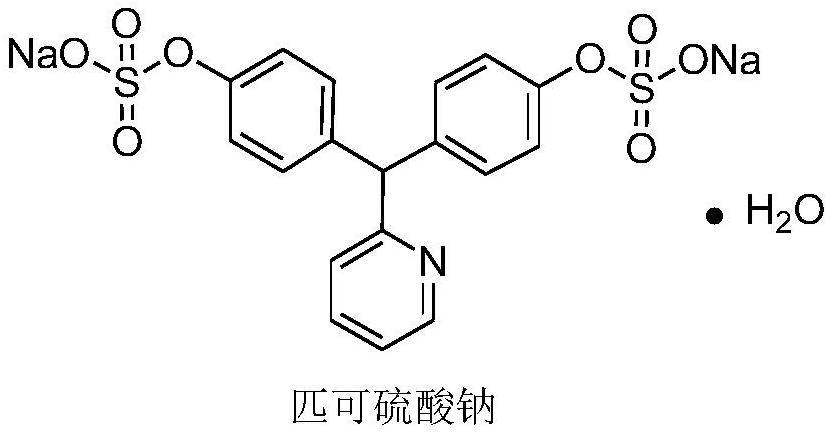

[0056] The reaction formula of embodiment 1 is as follows:

[0057]

[0058] The compound bisacodyl (200g, 1.0eq) was added to 95% ethanol (1000mL), and under stirring, 3mol / L sodium hydroxide aqueous solution (830mL, 4.5eq) was added dropwise, the temperature was controlled at 30-40°C, and the dropwise addition time was About 2 hours, after the dropwise addition was completed, stir at room temperature for 2 hours, and TLC detected the reaction. After the reaction was complete, half of the liquid (900mL) was evaporated under reduced pressure, and water (800mL, 40v / w) was added to the remaining liquid, and activated carbon (10g , 0.05w / w), after stirring for 30min, suction filtration; under normal temperature stirring, dropwise add 3mol / L hydrochloric acid (480mL) to the filtrate to make pH=5-6, after normal temperature stirring for 30min, filter, and water (1000mL, 5v / w) Rinse the filter cake, and dry the solid under vacuum at 50° C. for 16 hours to obtain a white solid P-...

Embodiment 2

[0062] The reaction formula of embodiment 2 is as follows:

[0063]

[0064] In the middle, the compound bisacodyl (200g, 1.0eq) was added to 95% methanol (1000mL), and under stirring, 3mol / L sodium hydroxide aqueous solution (830mL, 4.5eq) was added dropwise, and the temperature was controlled at 40°C-50°C. The addition time is about 1 hour. After the dropwise addition is completed, stir at room temperature for 1-2 hours. TLC detects the reaction. After the reaction is complete, half of the liquid (900 mL) is evaporated under reduced pressure, and water (800 mL, 40 v / w) is added to the remaining liquid. Put in activated carbon (10g, 0.05w / w), stir for 30min, and then filter with suction; while stirring at room temperature, add 3mol / L sulfuric acid (240mL) dropwise to the filtrate to make the pH = 5-6, and stir for 30min at room temperature, then start to filter with suction , wash the filter cake with water (1000mL, 5v / w), and dry the solid under vacuum at 50°C for 16 hour...

Embodiment 3

[0068] The reaction formula of embodiment 3 is as follows:

[0069]

[0070] In the middle, the compound bisacodyl (200g, 1.0eq) was added to 95% ethanol (1000mL), and under stirring, a 3mol / L potassium hydroxide aqueous solution (830mL, 4.5eq) was added dropwise, the temperature was controlled at 20-30°C, and the The time is about 1 hour. After the dropwise addition is completed, stir at room temperature for 1-2 hours. TLC detects the reaction. After the reaction is complete, half of the liquid (900mL) is evaporated under reduced pressure, and water (800mL, 40v / w) is added to the remaining liquid, and put into Activated carbon (10g, 0.05w / w), after stirring for 30min, suction filtration; under stirring at room temperature, add 3mol / L hydrochloric acid (480mL) dropwise to the filtrate to make pH = 5-6, after stirring at room temperature for 30min, start suction filtration, Rinse the filter cake with water (1000 mL, 5 v / w), and dry the solid under vacuum at 50°C for 16 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com