Carbon-based full-printing perovskite solar cell based on ionic liquid additive and preparation method ofcarbon-based full-printing perovskite solar cell

A technology for solar cells and ionic liquids, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as poor stability and poor optoelectronic performance, achieve low cost, solve poor optoelectronic performance, improve The effect of transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the ionic liquid is 1-butyl-2,3-dimethylimidazolium tetrafluoroborate, and the solvent of the perovskite precursor is γ-butyrolactone. The specific implementation steps of preparation are as follows:

[0031] 1. Weigh 0.3842g PbI 2 , 0.128g CH 3 NH 3 1, 0.0069g 5-AVAI, the addition of 1-butyl-2,3-dimethylimidazolium tetrafluoroborate is precisely regulated and controlled to be 1.21mg, and above-mentioned material is completely dissolved in the gamma-butyrolactone of 1mL to obtain A perovskite precursor solution A with ionic liquid added;

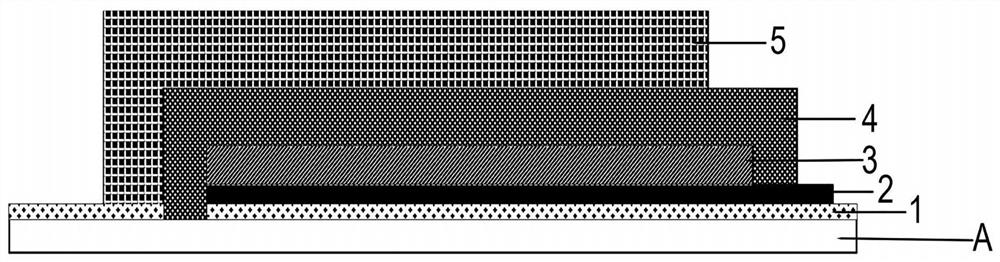

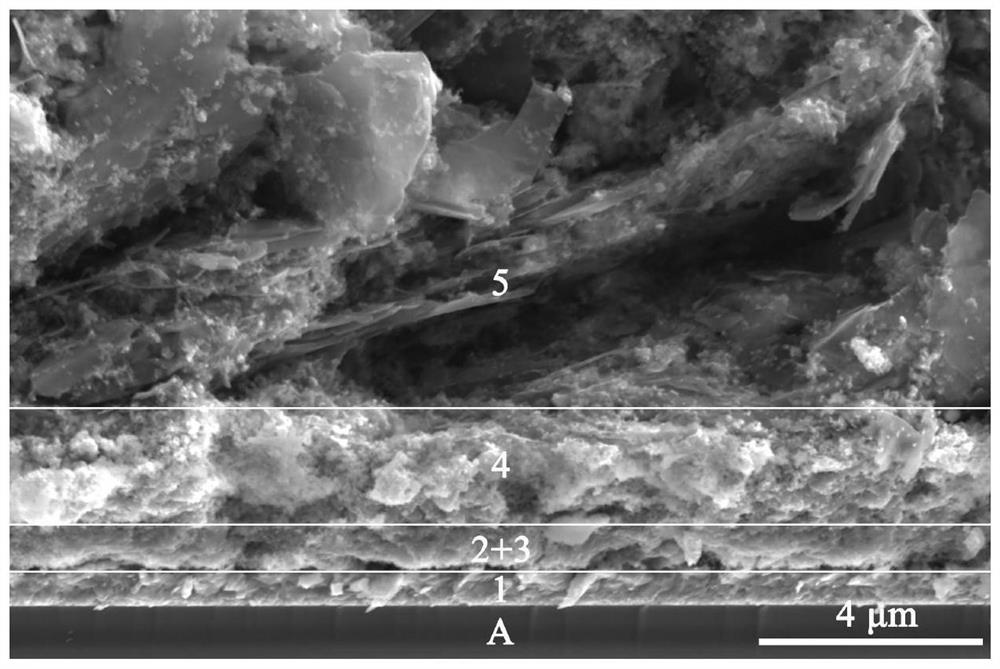

[0032] 2. Prepare a hole blocking layer, an electron transport layer, an insulating spacer layer and an anode layer on the FTO glass substrate in sequence. The hole blocking layer is prepared by spray pyrolysis, and the hole blocking layer is dense TiO 2 , with a thickness of 50nm; the three mesoporous layers such as the electron transport layer, the insulating spacer layer and the anode layer are all printed ...

Embodiment 2

[0040] In this embodiment, the ionic liquid is 1-butyl-3-methylimidazolium iodide, and the perovskite precursor solvent is a DMF / DMSO mixed solvent. The specific implementation steps of preparation are as follows:

[0041] 1. Weigh 0.461g PbI 2 , 0.159g CH 3 NH 3 1, the addition of 1-butyl-3-methylimidazolium iodonium salt of precise regulation and control is 2.17mg, and above-mentioned material is dissolved in 1mL DMF / DMSO mixed solvent (by volume meter ratio 4:1) to obtain adding ionic liquid The perovskite precursor solution B;

[0042] 2. Prepare a hole blocking layer, an electron transport layer, an insulating spacer layer and an anode layer on the FTO glass substrate in sequence. The hole blocking layer is preferably prepared by spray pyrolysis, and the hole blocking layer is dense TiO 2 , with a thickness of 50nm; the three mesoporous layers such as the electron transport layer, the insulating spacer layer and the anode layer are all printed by a screen printing pr...

Embodiment 3

[0054] Referring to Example 2, the difference is that the added ionic liquid is methylamine acetate, and its added amount is precisely controlled to be 13.67 mg.

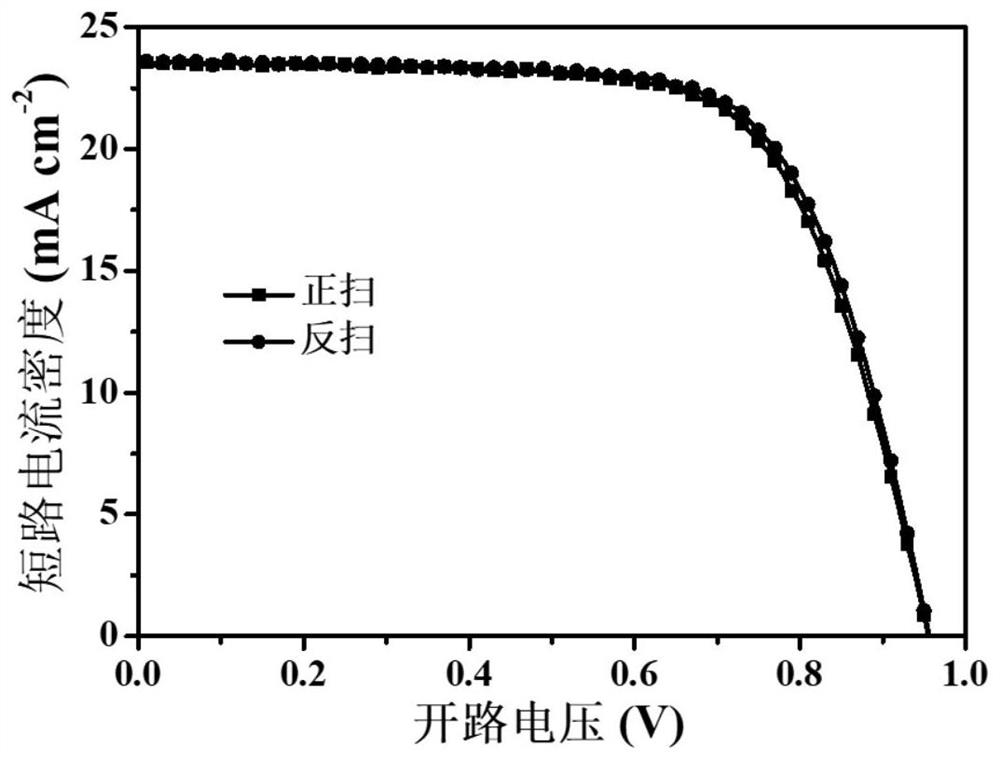

[0055] The J-V test was carried out on the prepared device, and the anti-sweep short-circuit current of the device was 19.44mA / cm 2 , the open circuit voltage is 0.93V, the fill factor is 72.55%, the photoelectric conversion efficiency is 13.12%; the positive scan short circuit current is 19.77mA / cm 2 , the open circuit voltage is 0.95V, the fill factor is 69.53%, and the photoelectric conversion efficiency is 13.06%. Positive and reverse scan hysteresis coefficient: 0.46%.

[0056] Comparing Example 3 with Comparative Example 2, it can be seen that the short-circuit current density, open-circuit voltage, fill factor and photoelectric conversion efficiency of the carbon-based all-printed perovskite solar cell prepared by adding the ionic liquid of this embodiment are greatly improved, and the device's The hysteres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com