Flame-retardant electrolyte, preparation method and lithium metal battery

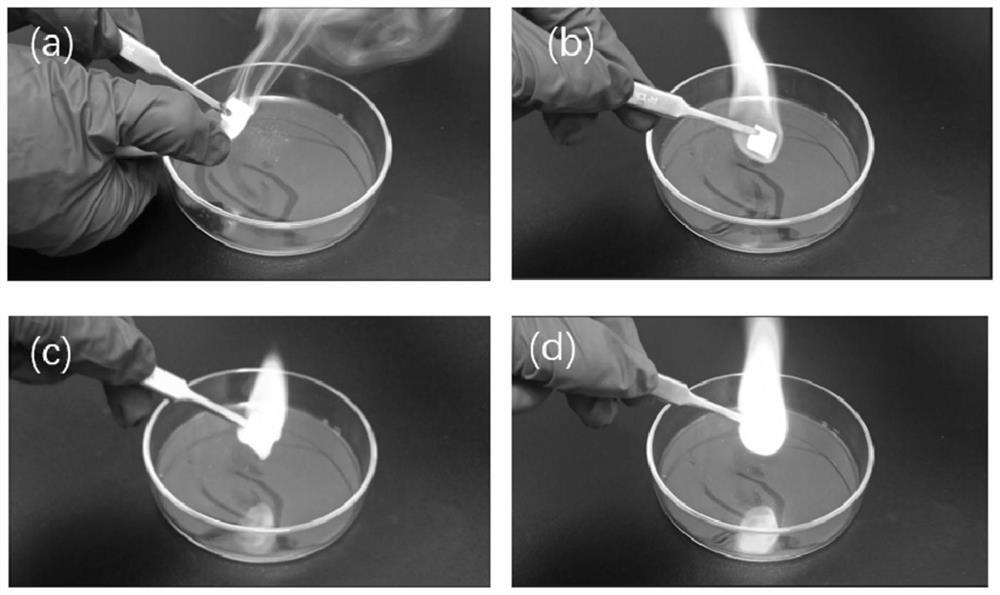

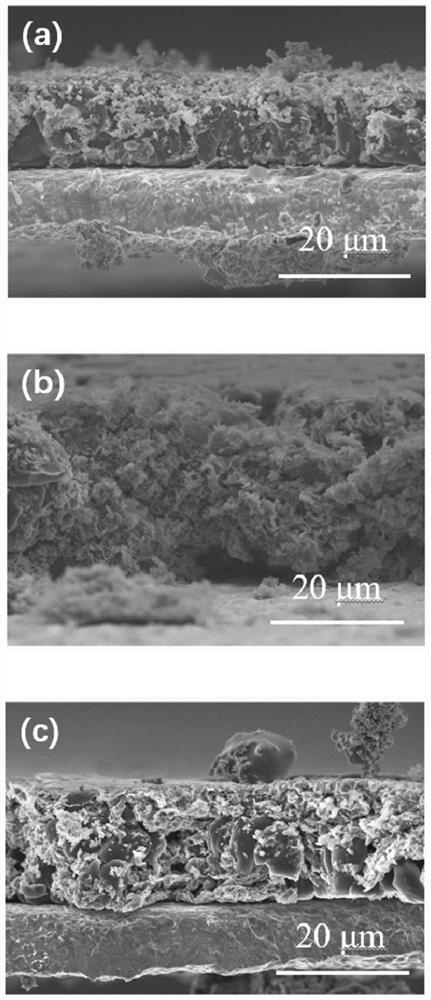

A lithium metal battery and electrolyte technology, applied in the field of lithium metal battery, preparation, and flame-retardant electrolyte, can solve problems such as damage, battery short circuit, and prone to side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present application also provides a method for preparing a flame-retardant electrolyte, comprising the steps of:

[0034] Step 1, adding lithium salt to the first component, stirring evenly to obtain a mixed solution;

[0035] Step 2: Add the second component into the mixed solution and stir evenly to obtain the flame-retardant electrolyte.

[0036] The preparation method of the flame-retardant electrolyte is simple, easy to realize industrialization, and is a high-safety lithium metal battery electrolyte with great commercial value.

[0037] The present application also provides a lithium metal battery, including a lithium metal negative electrode, a separator and a positive electrode, the separator is arranged between the lithium metal negative electrode and the positive electrode, the lithium metal battery also includes an electrolyte, the electrolyte is the flame-retardant electrolyte. The positive electrode is one of lithium cobalt oxide, lithium manganese ox...

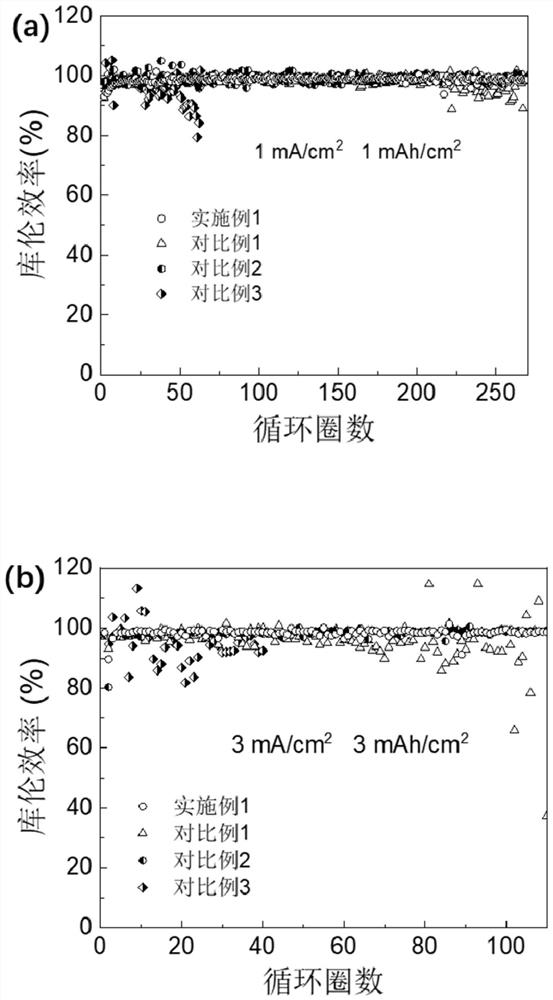

Embodiment 1

[0041] Add lithium bisfluorosulfonyl imide to ethylene glycol dimethyl ether (the first component) at a concentration of 4 mol / L, stir well, and then add 75% mass fraction of ethoxy (pentafluoro)cyclotriphosphazene (the second component), stirring for 5 hours to obtain a uniform flame-retardant electrolyte.

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that the mass fraction of the second component is 45%, and the remaining conditions are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com