Anti-hardening high-protein nutrient bar and preparation method thereof

A nutritional bar and high-protein technology, which is applied in protein food processing, animal protein processing, plant protein processing, etc., can solve the problems of restricting the development of the food market, unacceptable by consumers, hardening of texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

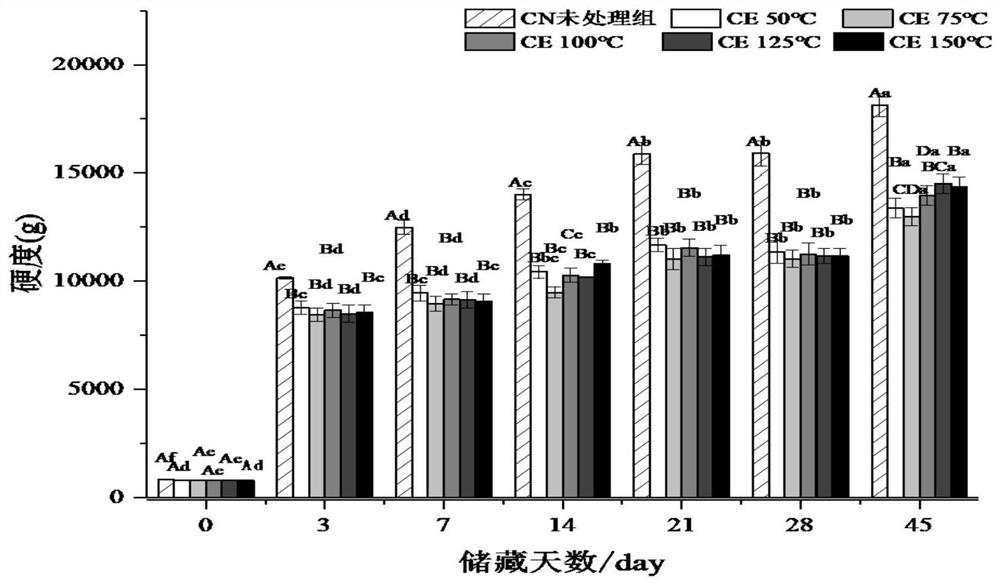

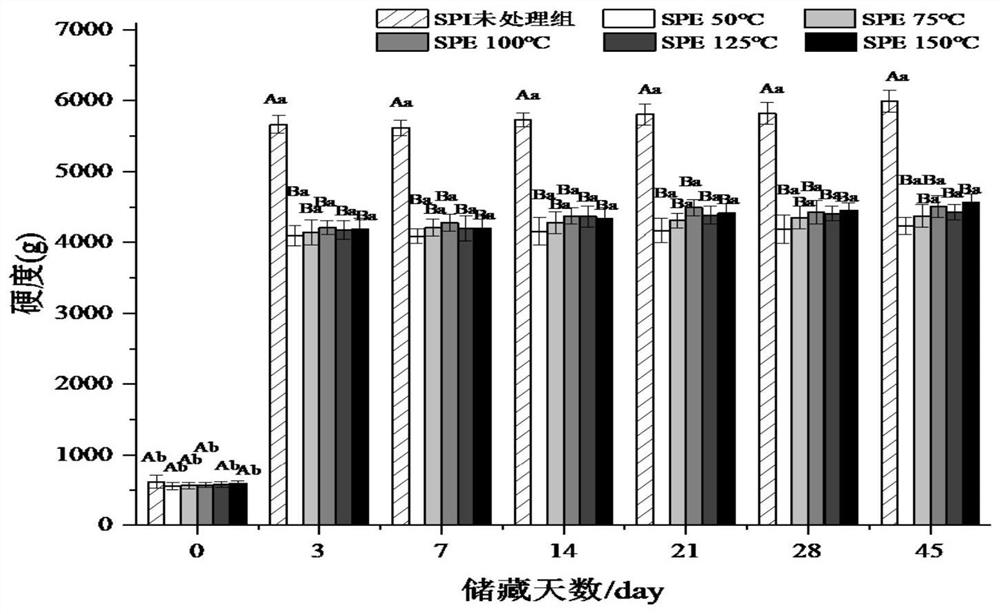

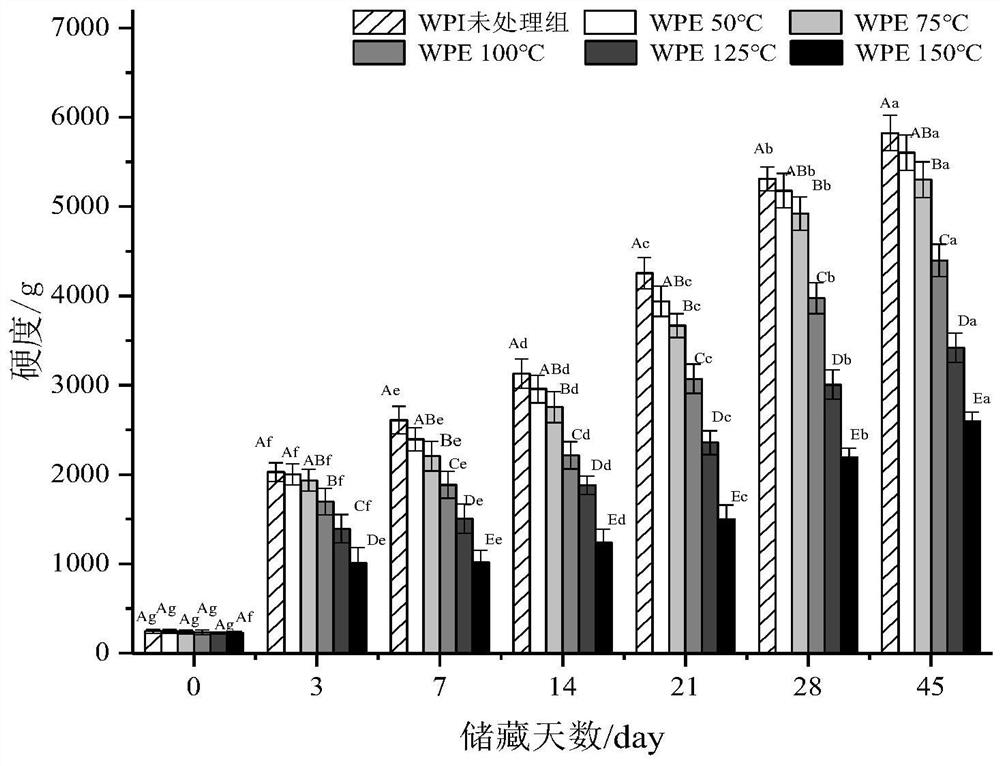

[0061] Sodium caseinate, soybean protein isolate and whey protein isolate were used as protein raw materials to prepare extrusion modified protein, and the specific process was as follows:

[0062] The moisture content of the protein raw material is adjusted to contain 40g of water per 100g, i.e. 40% moisture content, and the feeding speed is 60r / min. After co-rotating twin-screw extrusion of the extruder, extrudates with different extrusion temperatures can be obtained. Freeze-dry it and grind it to get extruded sodium caseinate (CE 50°C, CE 75°C, CE 100°C, CE 125°C, CE 150°C), extruded soybean protein isolate (SPE 50°C, SPE 75°C , SPE 100°C, SPE 125°C, SPE 150°C), extruded whey protein isolate (WPE 50°C, WPE 75°C, WPE 100°C, WPE 125°C, WPE 150°C). Then keep it sealed for later use.

[0063] The extruder used in this example has 8 independent heating zones (7 built-in heating zones and 1 external die heating zone). 100°C, 125°C, 150°C, the temperature of other heating zones...

Embodiment 2

[0088] Sodium caseinate, soybean protein isolate and whey protein isolate were used as protein raw materials to prepare enzymatically modified protein, and the specific process was as follows:

[0089] Prepare the protein material with pH 7.0 phosphate buffer to make a protein solution with a concentration of 10%, preheat to 45°C, add AS1.398 neutral protease (E / S=5%) to start the enzymatic hydrolysis reaction, and continue to place at 45 ℃ in a water bath to prepare whey protein hydrolyzate (WPH), soybean protein hydrolyzate (SPH) and casein hydrolyzate (CH), and measure the degree of hydrolysis (formaldehyde titration) at regular intervals. When the concentration reaches 10±0.5%, the hydrolysis reaction is stopped, and then the enzyme is inactivated at 95°C for 15 minutes, cooled, vacuum freeze-dried and dried for 12 hours, and WPH, SPH, and CH powders are prepared.

[0090] Weigh the unhydrolyzed protein material, high fructose syrup and glycerin according to the mass ratio...

Embodiment 3

[0114] The mixture of CE (extrusion temperature 100°C), SPE (extrusion temperature 50°C), and WPE (extrusion temperature 150°C) is used as the protein powder raw material for preparing anti-hardening high-protein nutrition bars, and the mass ratio is 9:8:3 The protein powder, glucose syrup and glycerin are mixed as raw materials. Design Expert 8.6.0 is used to set the addition amounts of CE, SPE and WPE as A1, B1 and C1 respectively, where A1+B1+C1=4g. According to the pre-experiment, the index settings, as shown in Table 20. Taking the addition ratio of CE, SPE, and WPE as variables, and taking the hardness, brightness, and sensory score of the high-protein nutrition bar as the response value, the level combinations of various factors designed using Design-expert mixture design are shown in Table 21. Using the hardness g, lightness L* and sensory scores of high-protein nutritional bars of each system stored for 7 days as the response values, the optimization analysis of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com