Hydroxyapatite/polyurethane porous bone repair material with shape memory

A technology of hydroxyapatite and repair materials, applied in medical science, tissue regeneration, prostheses, etc., can solve the problems of mismatching rate of degradation rate and rate of new bone formation, poor biocompatibility, complex molding process, etc., to achieve Good osteoinductivity, improved elasticity, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

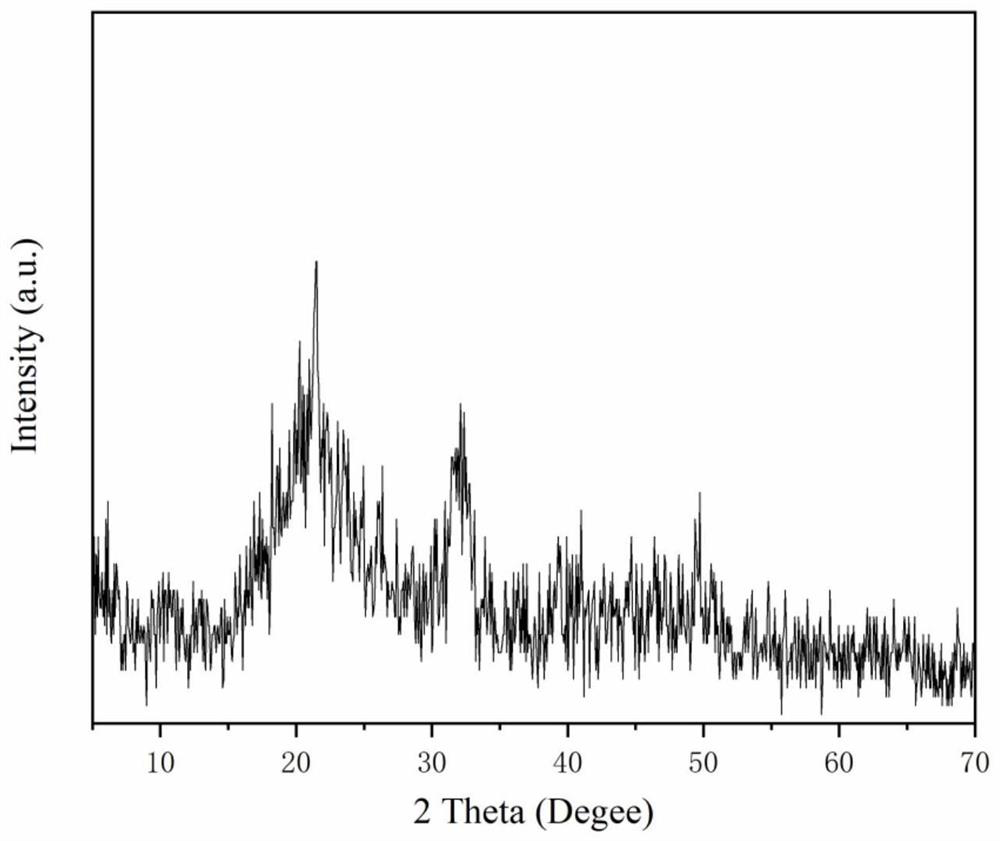

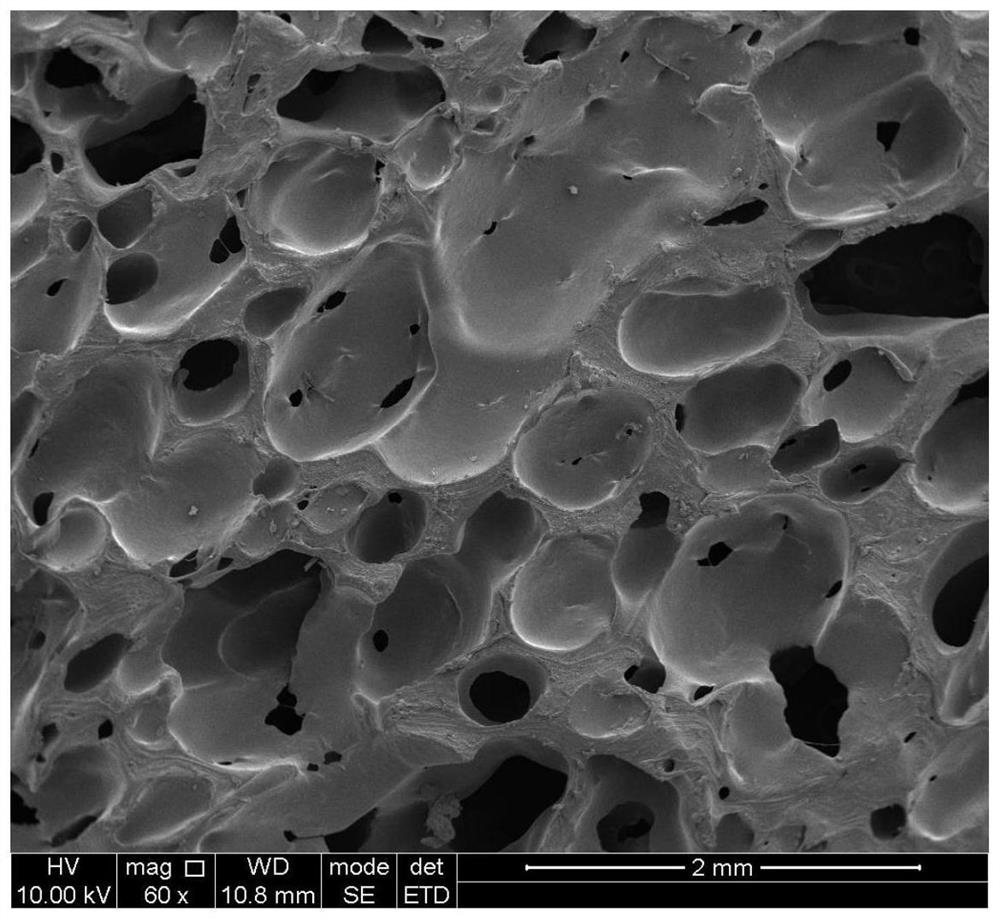

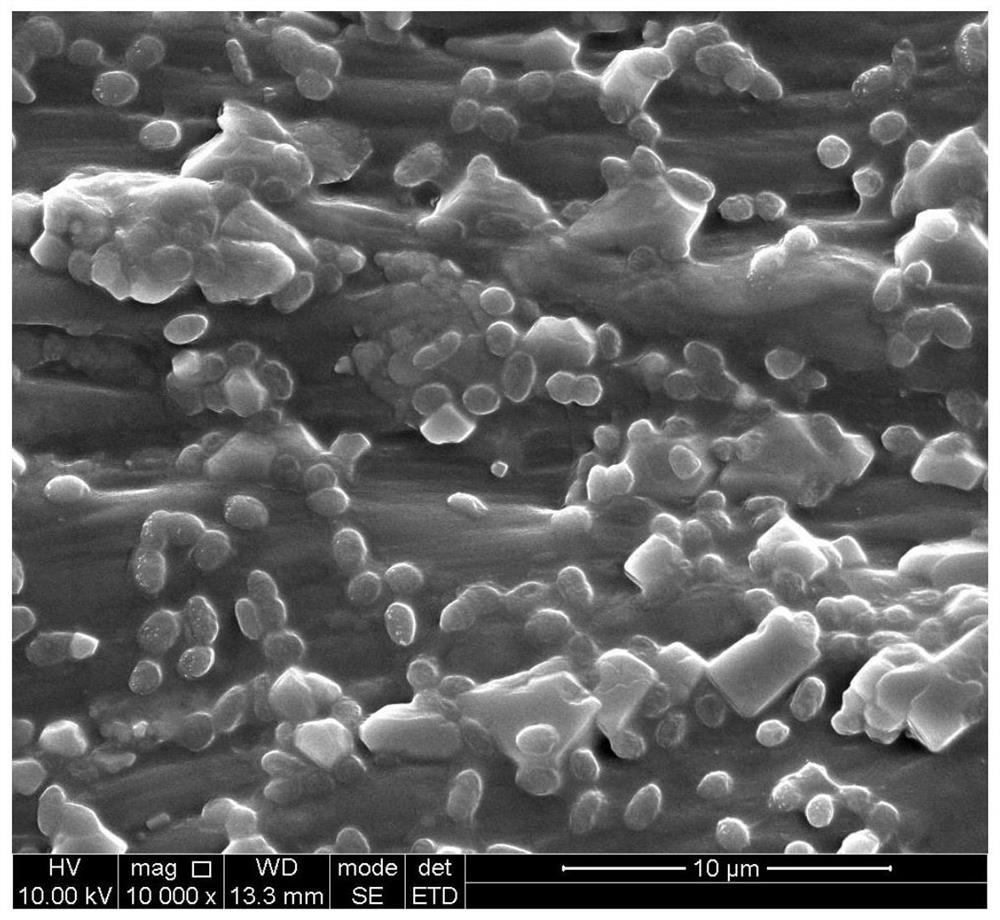

[0023] The hydroxyapatite / polyurethane porous composite bone repair material with shape memory provided in this example is composed of polycaprolactone, polytetrahydrofuran and hydroxyapatite, and the content of hydroxyapatite is 0% by mass percentage. The rest is the total content of polycaprolactone and polytetrahydrofuran, wherein the mass ratio of polycaprolactone and polytetrahydrofuran is 1:1; the molecular weight of polycaprolactone is 4000, and the molecular weight of polytetrahydrofuran is 3000. The specific implementation steps are as follows:

[0024] (1) take by weighing respectively 20 grams of polycaprolactone and 20 grams of polytetrahydrofuran with an electronic balance;

[0025] (2) Under a nitrogen environment, dissolve the weighed polycaprolactone and polytetrahydrofuran in dichloromethane, then add hydroxyapatite and mix uniformly at 80 ° C, and continue stirring to obtain a uniformly dispersed mixture; 300r / min;

[0026] (3) After mixing evenly, add 4ml of...

Embodiment 2

[0033] The hydroxyapatite / polyurethane porous composite bone repair material with shape memory provided in this example is composed of polycaprolactone, polytetrahydrofuran and hydroxyapatite, and the content of hydroxyapatite is 10% by mass percentage. The rest is the total content of polycaprolactone and polytetrahydrofuran, wherein the mass ratio of polycaprolactone and polytetrahydrofuran is 1:1; the molecular weight of polycaprolactone is 4000, and the molecular weight of polytetrahydrofuran is 3000. The specific implementation steps are as follows:

[0034] (1) each take by weighing 20 grams of polycaprolactone and polytetrahydrofuran and the hydroxyapatite of 4.444 grams with electronic balance;

[0035] (2) Under a nitrogen environment, dissolve the weighed polycaprolactone and polytetrahydrofuran in dichloromethane, then add hydroxyapatite and mix uniformly at 80 ° C, and continue stirring to obtain a uniformly dispersed mixture; 200r / min;

[0036] (3) After mixing ...

Embodiment 3

[0042] The hydroxyapatite / polyurethane porous composite bone repair material with shape memory provided in this example is composed of polycaprolactone, polytetrahydrofuran and hydroxyapatite, and the content of hydroxyapatite is 20% by mass percentage. The rest is the total content of polycaprolactone and polytetrahydrofuran, wherein the mass ratio of polycaprolactone and polytetrahydrofuran is 1:1; the molecular weight of polycaprolactone is 4000, and the molecular weight of polytetrahydrofuran is 3000. The specific implementation steps are as follows:

[0043] (1) each take by weighing 20 grams of polycaprolactone and polytetrahydrofuran and 10 grams of hydroxyapatite with electronic balance;

[0044] (2) Under a nitrogen environment, dissolve the weighed polycaprolactone and polytetrahydrofuran in dichloromethane, then add hydroxyapatite and mix uniformly at 80 ° C, and continue stirring to obtain a uniformly dispersed mixture; 250r / min;

[0045] (3) After mixing evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com