Early-strength high-impermeability concrete and preparation method thereof

An early-strength, concrete technology, applied in the field of underwater concrete, can solve the problems of waste of resources, excess slurry, and a large amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

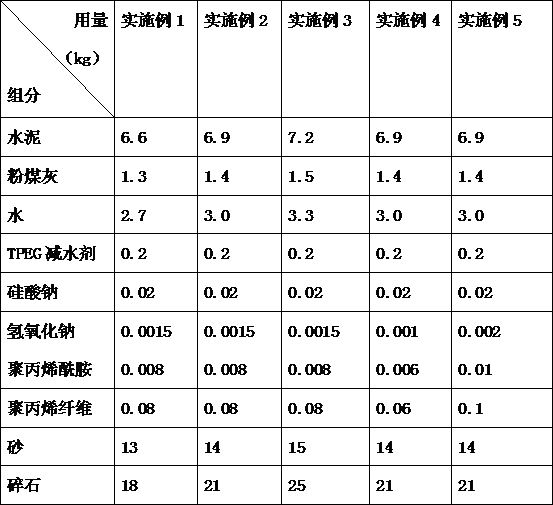

Examples

preparation example 1

[0039] The specific preparation raw materials of TPEG water reducer are: 150g isopentenol polyoxyethylene ether (hydroxyl value 25.5mgKOH / g, unsaturation 0.40mmol / g), 20g methacrylic acid, 13g sodium methacrylate, 18g Ethyl acrylate, 0.2g thioglycolic acid, 1g hydrogen peroxide aqueous solution (30% mass fraction), 0.5g vitamin C, 3g ammonium persulfate, 150g water and 5g sodium hydroxide aqueous solution (30% mass fraction).

[0040] The preparation method of TPEG water reducer is as follows: Pour isopentenol polyoxyethylene ether, hydrogen peroxide aqueous solution and water into a three-necked flask, then mix vitamin C, thioglycolic acid and ammonium persulfate evenly into component A, and put Mix methacrylic acid, sodium methacrylate and ethyl acrylate to form component B, heat the three-necked flask to 30 degrees Celsius and keep the temperature constant, then use a peristaltic pump to simultaneously drop component A and component B into the three-necked flask, two The co...

preparation example 2

[0042] The difference between this preparation example and preparation example 1 is that the specific preparation raw materials of TPEG water reducer are: 170g isopentenol polyoxyethylene ether (hydroxyl value 25.5mgKOH / g, unsaturation 0.40mmol / g), 25g methyl Acrylic acid, 19g sodium methacrylate, 23g ethyl acrylate, 0.7g mercaptoacetic acid, 5g hydrogen peroxide aqueous solution (30% mass fraction), 1.5g vitamin C, 6g ammonium persulfate, 170g water and 7g sodium hydroxide Aqueous solution (mass fraction 30%).

preparation example 3

[0044] The difference between this preparation example and preparation example 1 is: the hydroxyl value of prenol polyoxyethylene ether is 28mgKOH / g, the degree of unsaturation is 0.6mmol / g, the mass concentration of hydrogen peroxide aqueous solution is 25%, sodium hydroxide The mass concentration of the aqueous solution is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com