Electrochemical migration test method and device for power packaging

A test method and electrochemical technology, applied in measurement devices, nanotechnology for sensing, scientific instruments, etc., can solve the problems of difficult capture of migration process and difficulty of electrochemical migration observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

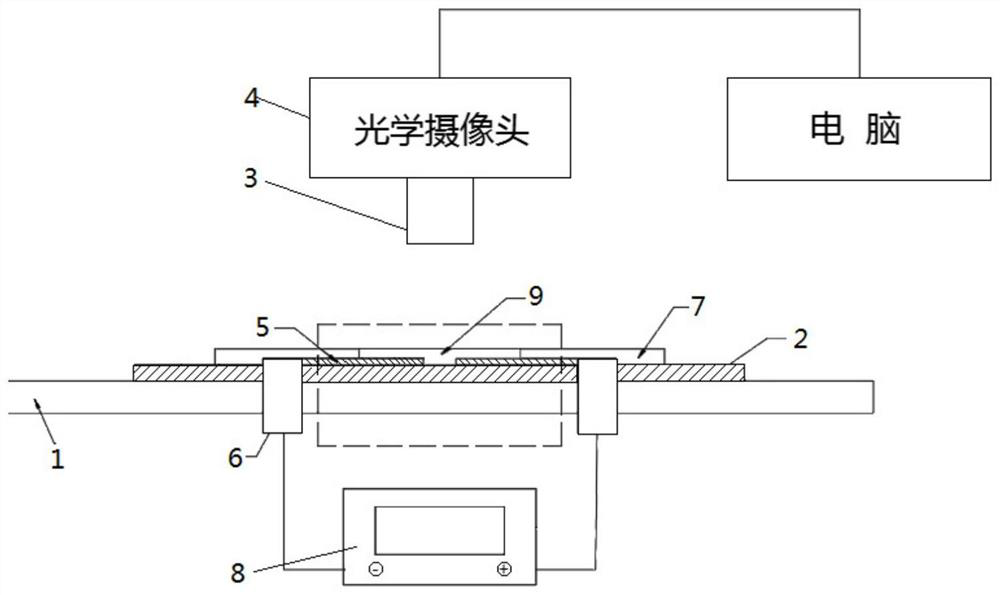

Method used

Image

Examples

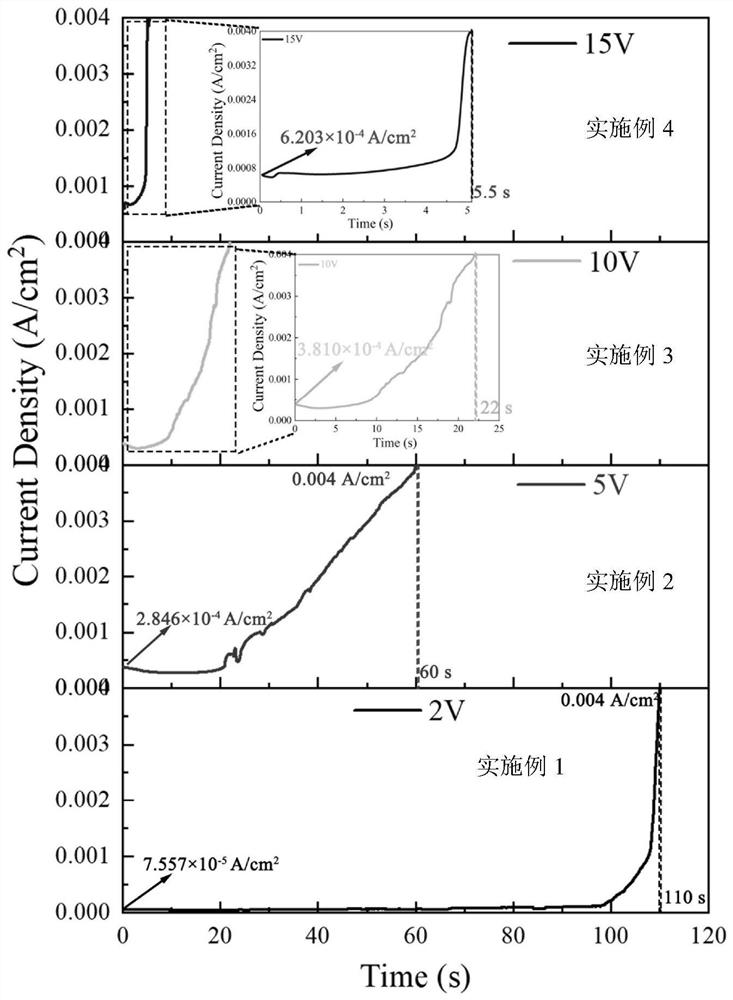

Embodiment 1

[0060] (1) Mix metal nanoparticles and organic solvents (ethyl cellulose, ethyl acetate, defoamer, terpineol, etc. at a mass ratio of 1:1:2:1:10) at a mass ratio of 6:4 Evenly, ultrasonic vibration is used for 5 minutes when mixing, the speed of the paste mixing machine is 700r / min, and the number of repetitions is 5 times, so as to obtain metal nano conductive ink; then use 200 mesh screen to print metal nano conductive ink on the alumina ceramic substrate , the distance between electrodes was controlled to be 0.5 mm. After the ink was naturally air-dried, the sample was pre-sintered in a tube furnace. The pre-treatment temperature was 50 °C, and the heating rate was 2 °C / min. Intensive pulsed light sintering, the pulsed light sintering parameters are: pulse energy 7.0 J / cm², pulse width 3000 us, repetition times 1, pulse form is single pulse, so as to complete the preparation of the sample to be tested for electrochemical migration.

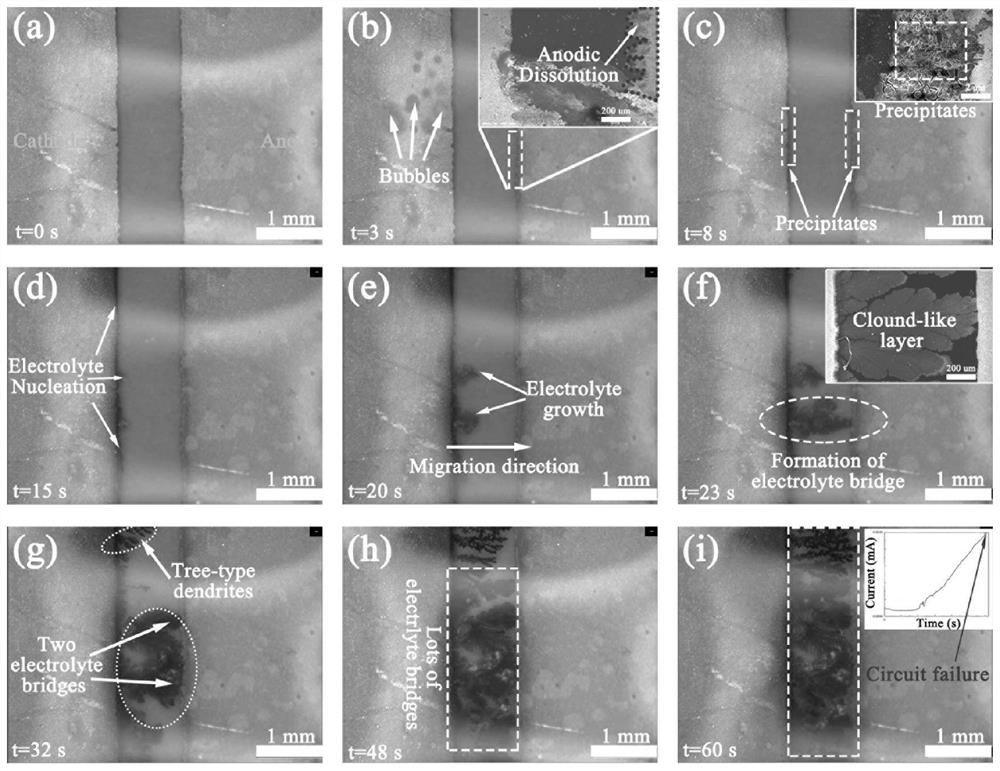

[0061] (2) Use the metal nano-ink patter...

Embodiment 2

[0064] (1) Mix metal nanoparticles and organic solvents (ethyl cellulose, ethyl acetate, defoamer, terpineol, etc. at a mass ratio of 1:1:2:1:10) at a mass ratio of 6:4 Evenly, ultrasonic vibration is used for 5 minutes when mixing, the speed of the paste mixing machine is 700r / min, and the number of repetitions is 5 times, so as to obtain metal nano conductive ink; then use 200 mesh screen to print metal nano conductive ink on the alumina ceramic substrate , the distance between electrodes was controlled to be 0.5 mm. After the ink was naturally air-dried, the sample was pre-sintered in a tube furnace. The pre-treatment temperature was 50 °C, and the heating rate was 2 °C / min. Intensive pulsed light sintering, the pulsed light sintering parameters are: pulse energy 7.0 J / cm², pulse width 3000 us, repetition times 1, pulse form is single pulse, so as to complete the preparation of the sample to be tested for electrochemical migration.

[0065] (2) Use the metal nano-ink patter...

Embodiment 3

[0068] (1) Mix metal nanoparticles and organic solvents (ethyl cellulose, ethyl acetate, defoamer, terpineol, etc. at a mass ratio of 1:1:2:1:10) at a mass ratio of 6:4 Evenly, ultrasonic vibration is used for 5 minutes when mixing, the speed of the paste mixing machine is 700r / min, and the number of repetitions is 5 times, so as to obtain metal nano conductive ink; then use 200 mesh screen to print metal nano conductive ink on the alumina ceramic substrate , the distance between electrodes was controlled to be 0.5 mm. After the ink was naturally air-dried, the sample was pre-sintered in a tube furnace. The pre-treatment temperature was 50 °C, and the heating rate was 2 °C / min. Intensive pulsed light sintering, the pulsed light sintering parameters are: pulse energy 7.0 J / cm², pulse width 3000 us, repetition times 1, pulse form is single pulse, so as to complete the preparation of the sample to be tested for electrochemical migration.

[0069] (2) Use the metal nano-ink pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com