Diesel engine oil composition and preparation method thereof

An oil composition and composition technology, applied in the field of lubricating oil, can solve the problems of strong steric hindrance effect, low freezing point, anti-oxidation performance, etc., and achieve the effects of inhibiting coking, improving anti-oxidation performance, and good piston cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

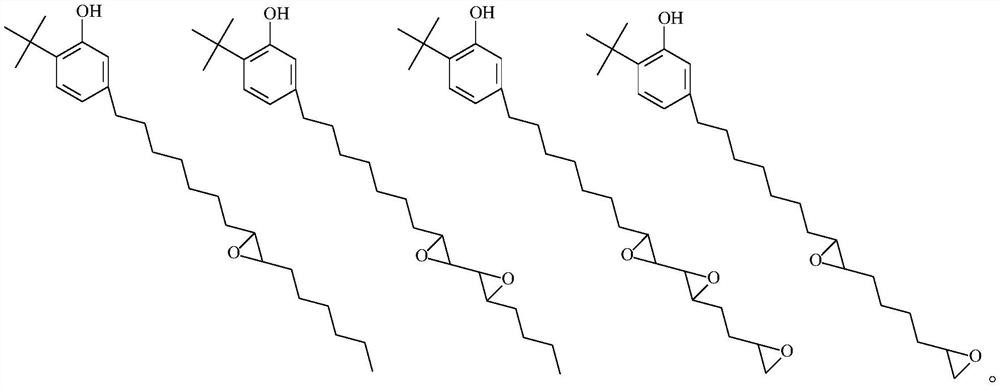

[0066] The preparation of embodiment 1 epoxidized cardanol

[0067] Take 100 g of cardanol, 8 g of formic acid, 0.3 g of sulfuric acid, and 200 g of hydrogen peroxide, put them in a three-necked flask with mechanical stirring, a reflux condenser and temperature control, and turn on stirring and heating. The reaction temperature was maintained at 70°C, and the reaction was carried out for 3 hours. After the reaction was completed, the temperature was lowered to obtain a brown-red transparent liquid. The reaction product was filtered, washed with 5% KOH solution, then washed with distilled water until neutral, and the organic phase was distilled under reduced pressure at 100Pa and 150°C for 1h to remove water and unreacted raw materials to obtain orange-red transparent liquid , denoted as H-1. The conversion rate of the product was 96.2%, and the purity of the epoxidized cardanol was more than 98%.

Embodiment 2

[0068] The preparation of embodiment 2 epoxidized cardanol

[0069] Take 100g of cardanol and add it to a three-necked flask with mechanical stirring, reflux condenser and temperature control, start stirring and heating. The reaction temperature was maintained at 12° C., 150 g of m-chloroperoxybenzoic acid was slowly added, and the reaction was carried out for 5 hours. After the reaction was completed, the temperature was lowered to obtain a brown-red transparent liquid. The reaction product was filtered, washed with 5% KOH solution, then washed with distilled water until neutral, and the organic phase was distilled under reduced pressure at 100Pa and 150°C for 1h to remove water and unreacted raw materials to obtain orange-red transparent liquid , denoted as H-2. The conversion rate of the product was 97.6%, and the purity of the epoxidized cardanol was more than 98%.

Embodiment 3

[0070] Example 3 Preparation of 2-tert-butyl-4-epoxypentadecylphenol

[0071] 35g of epoxidized cardanol prepared in Example 1 was dissolved in 100ml of acetone, put into a 250ml three-necked reaction flask after being dissolved, 0.9g of zinc chloride catalyst was added, stirring and heating were started, and the reaction temperature was maintained at 60°C. 9.5 g of tert-butyl chloride was slowly added dropwise to the reaction flask, and the reaction was continued for 3 hours after the dropwise addition was completed. After the reaction was completed, the temperature was lowered to obtain a brown-red transparent liquid. The reaction product was filtered, washed with 5% KOH solution, then washed with distilled water until neutral, and distilled under reduced pressure at 1000Pa and 120°C for 1 h to remove the solvent, water and unreacted raw materials to obtain a dark brown-red viscous Liquid, denoted as F-1. Product conversion was 81.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com