Preparation method of molybdenum carbide-loaded carbon-coated iron catalyst and application thereof in selective hydroxylation reaction of benzene ring

An iron catalyst, molybdenum carbide technology, applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high chemical stability of aromatic rings, reduce reaction selectivity, etc., to improve yield and selectivity, promoting circulation, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

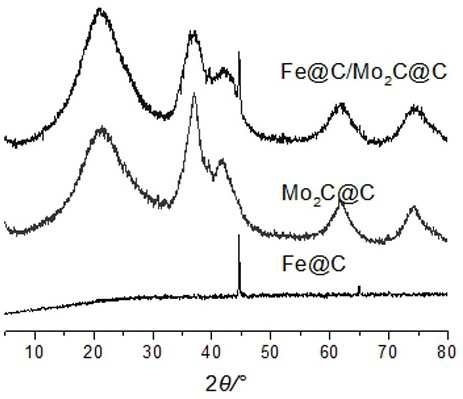

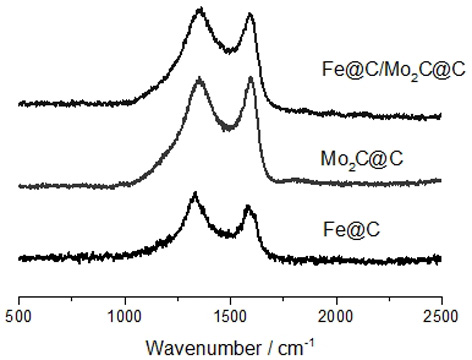

[0027] (1) Add 1 g MoCl 5 Dissolve in 10 mL of ethanol to form a green transparent solution, then add 2 g of urea and stir for 1 h. Then 1 g of glucose was added, the solvent was evaporated to dryness, and the sample was annealed in a tube furnace at 800 °C for 3 h under an argon atmosphere to obtain Mo 2 C@C.

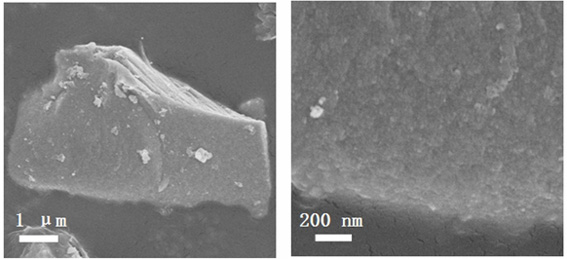

[0028] (2) Add 0.6 g FeCl 3 ·6H 2 O and 1.2 g of dicyandiamide were dispersed in deionized water, stirred in a water bath at 80°C for 2 h to fully coordinate the two, and then 1 g of Mo was added. 2 C@C, continue heating and stirring for 2 h until the liquid evaporates to dryness. The obtained solid was ground, and programmed annealing in a tube furnace under an argon atmosphere. The annealing temperature of the first stage was 550 °C for 2 h, and the annealing temperature of the second stage was 700 °C for 2 h to obtain Fe@ C / Mo 2 C@C crude product. The sample was washed with 6 mol / L HCl solution for 24 h, centrifuged and dried in vacuum to obtain Fe@C / Mo 2 C@...

Embodiment 2

[0033] 0.6 g FeCl 3 ·6H 2 O and 1.2 g of dicyandiamide were dispersed in deionized water, stirred in a water bath at 80°C for 2 h to fully coordinate the two, and then 1 g of commercially available Mo was added. 2 C, continue heating and stirring for 2 h until the liquid evaporates to dryness. The obtained solid was ground, and programmed annealing in a tube furnace under an argon atmosphere. The annealing temperature of the first stage was 550 °C for 2 h, and the annealing temperature of the second stage was 700 °C for 2 h to obtain Fe@ C / Mo 2 C crude product. The sample was washed with 6 mol / L HCl solution for 24 h, centrifuged and dried in vacuum to obtain Fe@C / Mo 2 c.

Embodiment 3

[0035] (1) Prepare two solutions A and B, solution A is 1 g MoCl 5 Dissolve in 10 mL ethanol to form a green transparent solution, then add 2 g urea and stir for 1 h. Solution B is to dissolve 1.5 g of Pluronic F127 powder in 10 mL of ethanol. Solution B was added dropwise to solution A, and the solvent was removed after mixing and stirring for 4 h. The sample was annealed at 800 °C for 3 h in a tube furnace under an argon atmosphere to obtain porous Mo 2 C (Porous-Mo 2 C).

[0036] (2) Add 0.6 g FeCl 3 ·6H 2 O and 1.2 g of dicyandiamide were dispersed in deionized water, stirred in a water bath at 80 °C for 2 h to fully coordinate the two, and then 1 g of Porous-Mo 2 C, continue heating and stirring for 2 h until the liquid evaporates to dryness. The obtained solid was ground, and programmed annealing in a tube furnace under an argon atmosphere. The annealing temperature of the first stage was 550 °C for 2 h, and the annealing temperature of the second stage was 700 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com