Pharmaceutical-grade zinc chloride bulk drug and preparation method thereof

A zinc chloride, pharmaceutical-grade technology, applied in the field of medicine, to achieve the effect of qualified alkali metal and alkaline earth metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

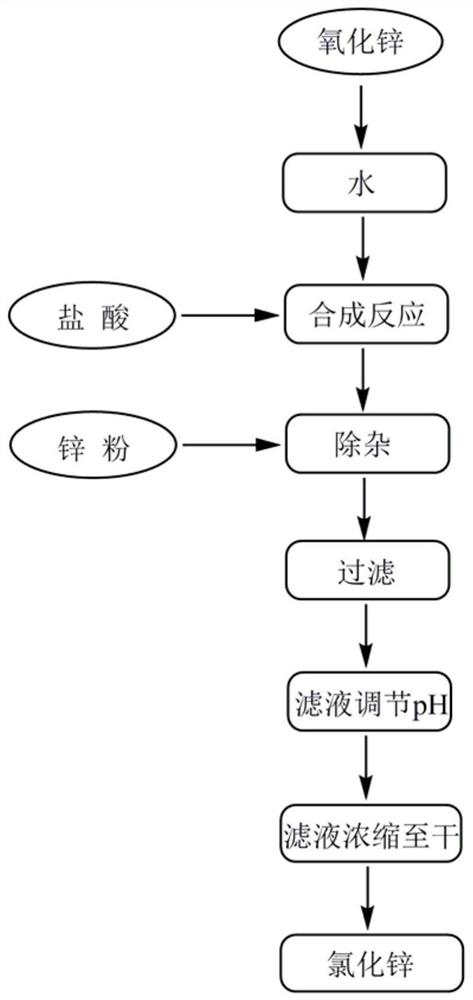

Method used

Image

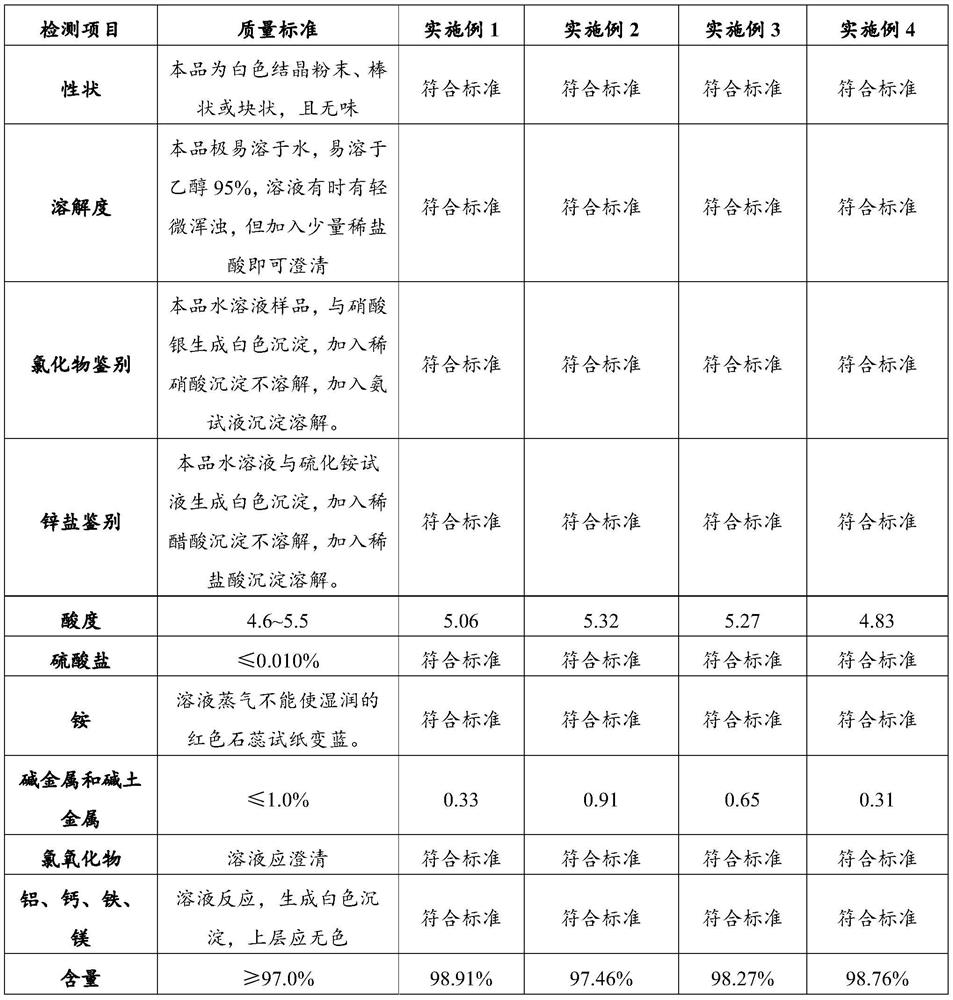

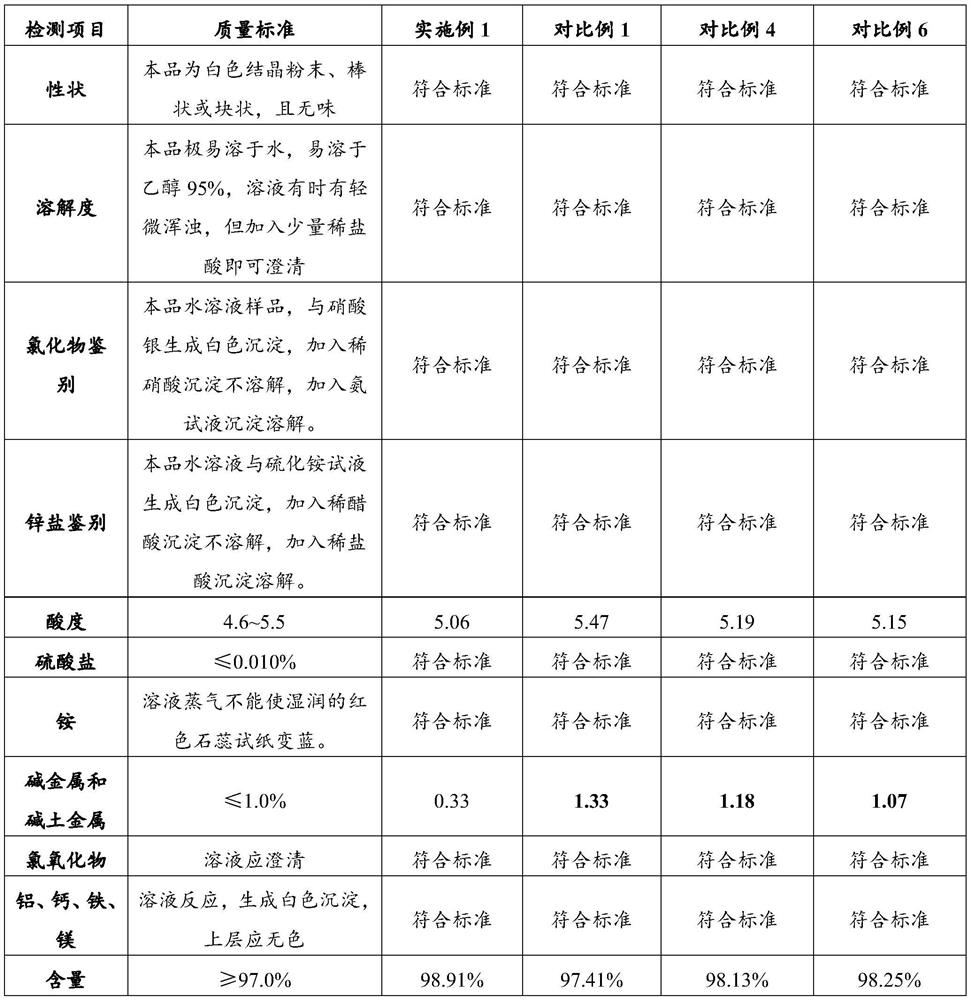

Examples

Embodiment 1

[0033] Put 300.00g of purified water and 100.00g of zinc oxide into a 1L four-neck flask (kettle) equipped with a mechanical stirring device, turn on the mechanical stirring device, and mix the zinc oxide and water to obtain a suspension;

[0034] Then 261.24g mass fraction of 36% hydrochloric acid is added in the constant pressure dropping funnel, the molar ratio of zinc oxide and hydrochloric acid is controlled to be 1:2.1, slowly open the valve of the constant pressure dropping funnel, let the hydrochloric acid slowly Drop in the four-necked flask (still), because the reaction exothermic is obvious, therefore need to control the temperature in the four-necked flask (still) below 80 ℃, after the hydrochloric acid drops, record the temperature in the four-necked flask (still), Stir and react until the system is clear and transparent to obtain the first reaction solution;

[0035] Add 20g of zinc powder to the four-necked flask (still) containing the first reaction solution, t...

Embodiment 2

[0039] Put 300.00g of purified water and 100.00g of zinc oxide into a 1L four-neck flask (kettle) equipped with a mechanical stirring device, turn on the mechanical stirring device, and mix the zinc oxide and water to obtain a suspension;

[0040] Then 236.36g mass fraction of 36% hydrochloric acid is added to the constant pressure dropping funnel, the molar ratio of zinc oxide and hydrochloric acid is controlled to be 1:1.9, the valve of the constant pressure dropping funnel is slowly opened, and the hydrochloric acid is slowly Drop in the four-necked flask (still), because the reaction exothermic is obvious, therefore need to control the temperature in the four-necked flask (still) below 70 ℃, after the hydrochloric acid drops, record the temperature in the four-necked flask (still), Stir and react until the system is clear and transparent to obtain the first reaction solution;

[0041] Add 19g of zinc powder to the four-necked flask (still) filled with the first reaction so...

Embodiment 3

[0045] Put 300.00g of purified water and 100.00g of zinc oxide into a 1L four-neck flask (kettle) equipped with a mechanical stirring device, turn on the mechanical stirring device, and mix the zinc oxide and water to obtain a suspension;

[0046]Then 248.80g mass fraction of 36% hydrochloric acid is added to the constant pressure dropping funnel, the molar ratio of zinc oxide and hydrochloric acid is controlled to be 1:2.0, the valve of the constant pressure dropping funnel is slowly opened, and the hydrochloric acid is slowly Drop in the four-necked flask (still), because the reaction exothermic is obvious, therefore need to control the temperature in the four-necked flask (still) below 80 ℃, after the hydrochloric acid drops, record the temperature in the four-necked flask (still), Stir and react until the system is clear and transparent to obtain the first reaction solution;

[0047] Add 20g of zinc powder to the four-necked flask (still) containing the first reaction solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com