Production method of microbial soil conditioner

A technology of soil improver and production method, applied in the field of soil improver, which can solve the problems of sparse plant growth, soil damage, time-consuming and labor-intensive efficiency, and achieve the effects of avoiding damage to bacteria, convenient packaging and transportation, and improving fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

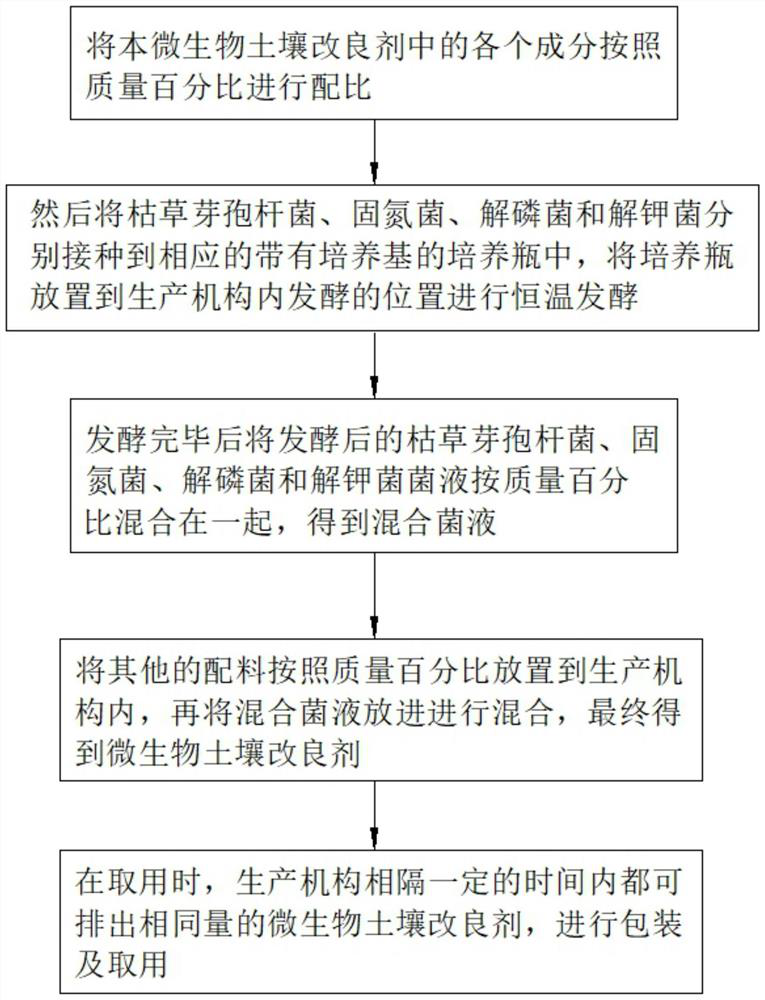

[0050] see figure 1 , a production method of microbial soil conditioner, comprising the steps of:

[0051] S1, firstly mix the components in the microbial soil improver according to the mass percentage, and wait for use after mixing;

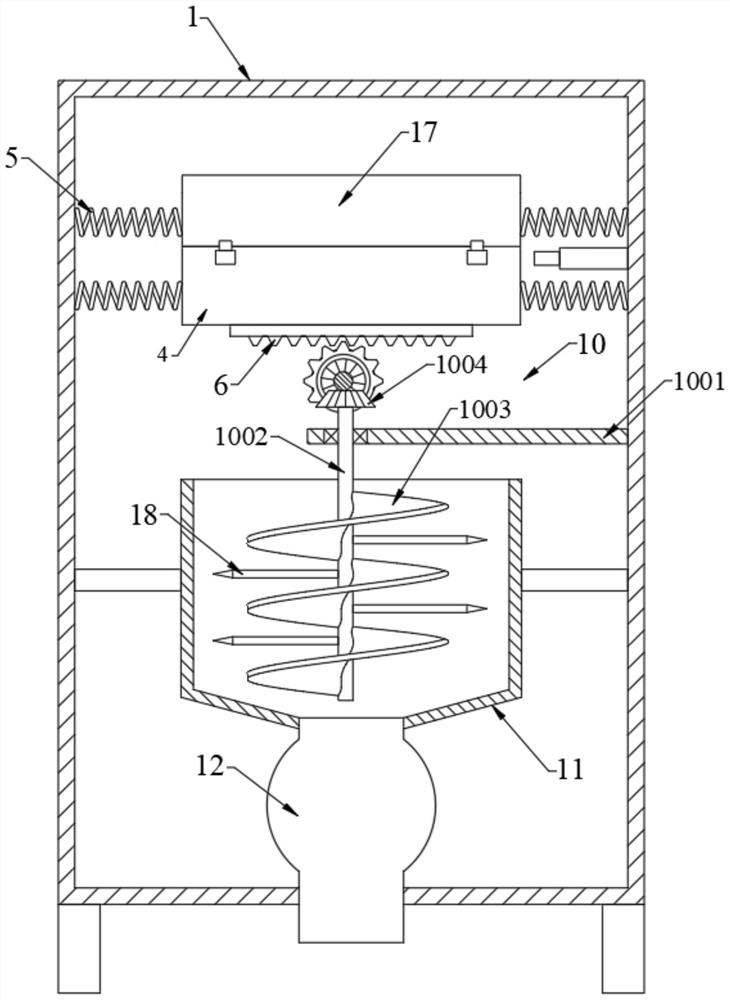

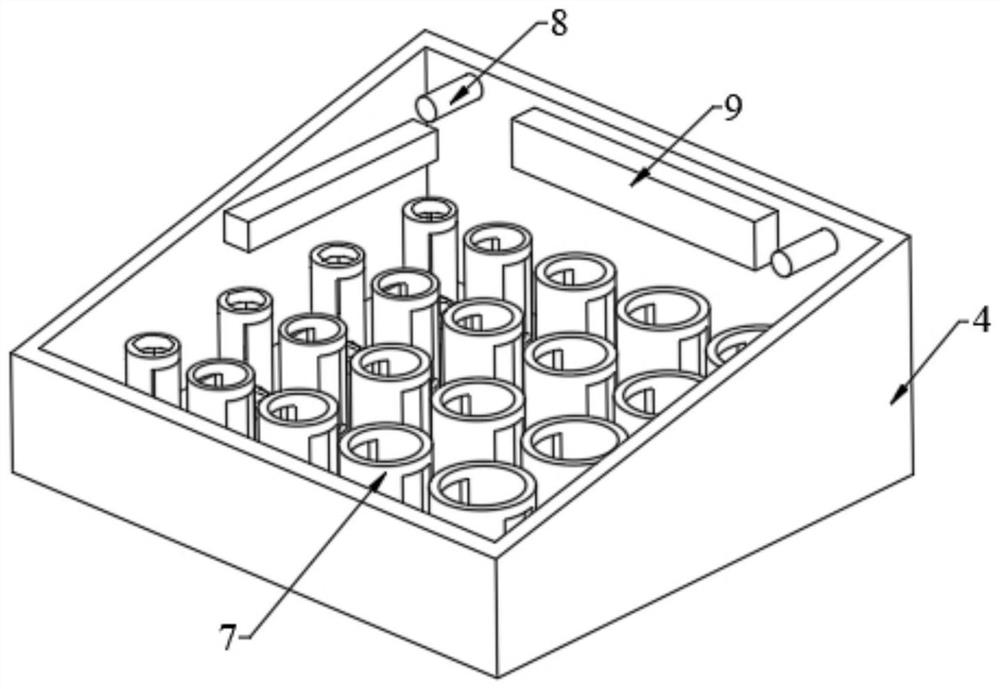

[0052] S2, then inoculate Bacillus subtilis, nitrogen-fixing bacteria, phosphorus-solubilizing bacteria and potassium-solubilizing bacteria into corresponding culture bottles with culture medium, and make multiple culture bottles according to needs, and then place the culture bottles in the production mechanism for fermentation The position of fermentation culture at a constant temperature corresponds to the corresponding time. The fermentation temperature of Bacillus subtilis, nitrogen-fixing bacteria, phosphorus-solubilizing bacteria and potassium-solubilizing bacteria is 30°C. , the fermentation time is 35 hours, to ensure sufficient fermentation time, to ensure that all bacteria are fermented, and to improve the effect of subsequent microbi...

Embodiment 2

[0069] On the basis of embodiment 1, a certain amount of the prepared microbial soil conditioner is placed in the inside of the filler ceramic ball, such as Figure 10 As shown, then plug the opening of the filler ceramic ball with a plug made of rice bran, which can be conveniently transported and used through the filler ceramic ball, poultry animals will have the habit of eating small stones, which is helpful for poultry digestion, and the filler ceramic ball Mixed in the poultry feed, when the poultry animal eats the filler ceramic ball into the stomach, it can have a warming effect on the filler ceramic ball in the poultry stomach, and improve the microbial activity in the microbial soil conditioner, during poultry defecation At this time, the filler ceramic balls will be discharged into the field. At this time, the microorganisms in the filler ceramic balls will slowly digest the plug, the plug will gradually degrade, and the microbial soil amendment inside will come out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com