Binding agent, organic carrier, front conductive silver paste, preparation method of front conductive silver paste and solar cell

A technology of conductive silver paste and organic carrier, which is applied in the field of solar cells to achieve excellent moisture retention, excellent linear flatness, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

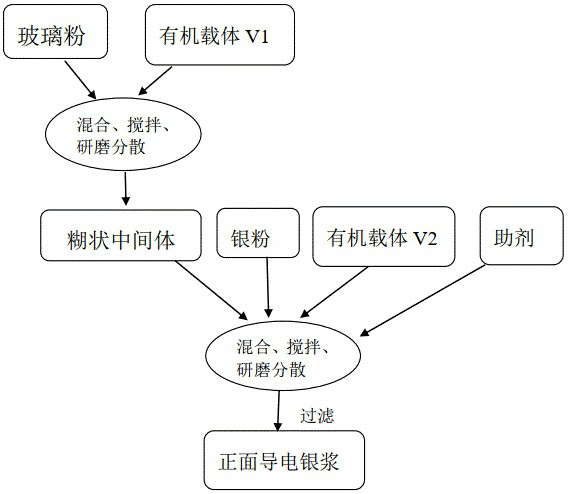

[0096] Such as figure 1 Shown, the 4th object of the present invention is to provide a kind of preparation method of solar cell positive conductive silver paste, comprising:

[0097] Preparation of a paste glass intermediate: mixing glass powder and the first organic carrier V1 in a certain proportion, grinding and dispersing, to prepare a paste glass intermediate.

[0098] The paste glass intermediate, the first silver powder P1, the second silver powder P2, the second organic vehicle V2, organic additives, etc. are mixed and stirred according to the proportion, and the front silver paste is obtained by grinding, dispersing and filtering.

[0099] Preferably, grinding and dispersing are performed by a three-roll machine for multiple times until the fineness of the front conductive silver paste is less than 5 μm and the viscosity is 70-90 pa.s. For example, the fineness of the front conductive silver paste is 4 μm, and the viscosity is 80 pa.s.

[0100] The invention uses th...

Embodiment 1

[0106] A high-efficiency solar cell front conductive silver paste suitable for ultra-fine line printing. The composition of the silver paste includes: 51wt% P1 silver powder; 38wt% P2 silver powder; 2.3wt% glass powder; 4.1wt% first organic vehicle V1; 3.6 wt% of the second organic vehicle V2; 1 wt% of organic additives.

[0107] In the specific embodiment, the raw material ratio of the first organic carrier V1 is: polyvinyl butyral (PVB) 2.2wt%, copolymerized modified PVP resin 3.7wt%, cellulose acetate butyrate (CAB) 1.4wt%, modified 1.5wt% non-toxic acrylic resin, 28wt% butyl carbitol, 48.2wt% butyl carbitol acetate, 7.5wt% propylene glycol butyl ether, 7.5wt% alcohol ester twelve.

[0108] In the specific embodiment, the raw material ratio of the second organic carrier V2 is: 4.2wt% of polyamide wax, 3.5wt% of polyalphamethylstyrene, 32.3wt% of butyl carbitol acetate, 50wt% of tripropylene glycol methyl ether, Dimethyl adipate 10wt%.

[0109] In the specific embodiment, ...

Embodiment 2

[0113] A high-efficiency solar cell front conductive silver paste suitable for ultra-fine line printing. The composition of the silver paste includes: 51wt% P1 silver powder; 38wt% P2 silver powder; 2.3wt% glass powder; 5.1wt% first organic vehicle V1; 2.6 wt% of the second organic vehicle V2; 1 wt% of organic additives.

[0114] In the specific embodiment, the raw material ratio of the first organic carrier V1 is: polyvinyl butyral (PVB) 2.2wt%, copolymerized modified PVP resin 3.7wt%, cellulose acetate butyrate (CAB) 1.4wt%, modified 1.5wt% non-toxic acrylic resin, 28wt% butyl carbitol, 48.2wt% butyl carbitol acetate, 7.5wt% propylene glycol butyl ether, 7.5wt% alcohol ester twelve.

[0115] In the specific embodiment, the raw material ratio of the second organic carrier V2 is: 4.2wt% of polyamide wax, 3.5wt% of polyalphamethylstyrene, 32.3wt% of butyl carbitol acetate, 50wt% of tripropylene glycol methyl ether, Dimethyl adipate 10wt%.

[0116] The preparation method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com