A kind of preparation method of high rate and high nickel composite positive electrode and its application

A composite cathode, high-rate technology, used in positive electrodes, battery electrodes, active material electrodes, etc., can solve problems such as limited transmission capacity, improve lithium ion conductivity, reduce lithium ion transmission paths, and reduce secondary particles. effect of diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

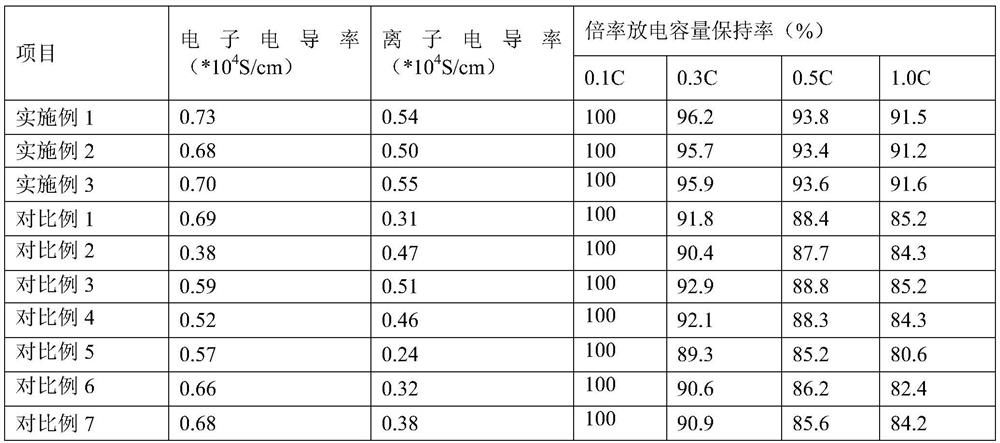

Examples

preparation example Construction

[0028] A preparation method of a high-rate and high-nickel composite positive electrode sheet, comprising the following preparation steps:

[0029] a. Preparation of hollow nano-carbon conductive agent HNC: Fe 3 O 4 The nanopowder is placed in a closed container. First, hydrogen is introduced at a rate of 0.1-0.3L / min, and the temperature is raised to 500-600°C at a rate of 4-6°C / min. The carbon dioxide was introduced at a rate of 0.5-1.2L / min for 7-20min and then stopped, the airtight container was kept for 3-6h, cooled to room temperature, the obtained powder was stirred in concentrated acid (concentrated hydrochloric acid or concentrated nitric acid) for 2.5-3h, filtered The powder is washed and placed in an argon atmosphere, heated to 2000-2500°C for 60-180min at 5-10°C / min, and sintered for 60-180min to obtain a highly graphitized hollow nano-carbon conductive agent HNC with low surface defects; Fe 3 O 4 The ratio of nano powder to the total amount of hydrogen introduc...

Embodiment 1

[0034] A preparation method of a high-rate and high-nickel composite positive electrode sheet, comprising the following preparation steps:

[0035] a. Preparation of hollow nano-carbon conductive agent HNC: Fe 3 O 4 The nanopowder was placed in a closed container. First, hydrogen was introduced at a rate of 0.2L / min, and the temperature was raised to 550°C at a rate of 5°C / min. After passing carbon dioxide for 15 min, it was stopped, the airtight container was kept for 4.5 h, cooled to room temperature, the obtained powder was stirred in concentrated hydrochloric acid for 2.8 h, the powder was filtered and washed, the powder was placed in an argon atmosphere, and the temperature was increased at 8 °C / min. Sintered at 2250 °C for 120 min to obtain highly graphitized hollow nano-carbon conductive agent HNC with low surface defects; Fe 3 O 4 The ratio of nano powder to the total amount of hydrogen introduced is 0.12:110;

[0036] b. Preparation of nano-Li 2 ZrO 3 Coating hi...

Embodiment 2

[0041] A preparation method of a high-rate and high-nickel composite positive electrode sheet, comprising the following preparation steps:

[0042] a. Preparation of hollow nano-carbon conductive agent HNC: Fe 3 O 4 The nanopowder was placed in a closed container. First, hydrogen was introduced at a rate of 0.1L / min, and the temperature was raised to 500°C at a rate of 4°C / min. After adding carbon dioxide for 7 min, stop, keep the airtight container for 3 h, cool to room temperature, stir the obtained powder in concentrated hydrochloric acid for 2.5 h, filter the powder and wash it, put the powder in an argon atmosphere, and heat up to 2000 at 5°C / min Sintered at ℃ for 60 min to obtain highly graphitized hollow nano-carbon conductive agent HNC with low surface defects; Fe 3 O 4 The ratio of nano-powder to the total amount of hydrogen introduced is 0.05:100;

[0043] b. Preparation of nano-Li 2 ZrO 3 Coating high-nickel cathode material: ZrO (NO 3 ) 2H 2 O, LiNO 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com