Co atom-doped polyhedral MOFs (Metal-Organic Frameworks) material as well as preparation method and application thereof

A technology of polyhedron and atom, which is applied in the field of Co atom-doped polyhedral MOFs materials and its preparation, can solve the problems of rare preparation of MOFs materials, low MOFs ORR activity, low energy density of zinc-air batteries, etc., and achieve excellent electrocatalytic activity , abundant reserves and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] An embodiment of the present invention provides a method for preparing a Co atom-doped polyhedral MOFs material, comprising the following steps:

[0039] (1) Add dimethylimidazole, zinc salt and cobalt salt to the methanol solution for precursor synthesis reaction, and the reaction product is separated and dried to obtain the precursor powder;

[0040] (2) Roasting dicyandiamide to prepare g-C 3 N 4 powder;

[0041] (3) Combine the precursor powder and g-C 3 N 4 The powder is ground and mixed uniformly to obtain a mixed powder, and the mixed powder is placed in an inert atmosphere for calcination;

[0042] (4) The product obtained after the calcination treatment is acid-washed with sulfuric acid, dried after solid-liquid separation, and the Co atom-doped polyhedral MOFs material is obtained.

[0043] Among them, in the precursor synthesis reaction in step (1), the zinc salt and cobalt salt can be commonly used water-soluble salts, and the zinc salt can be zinc nitr...

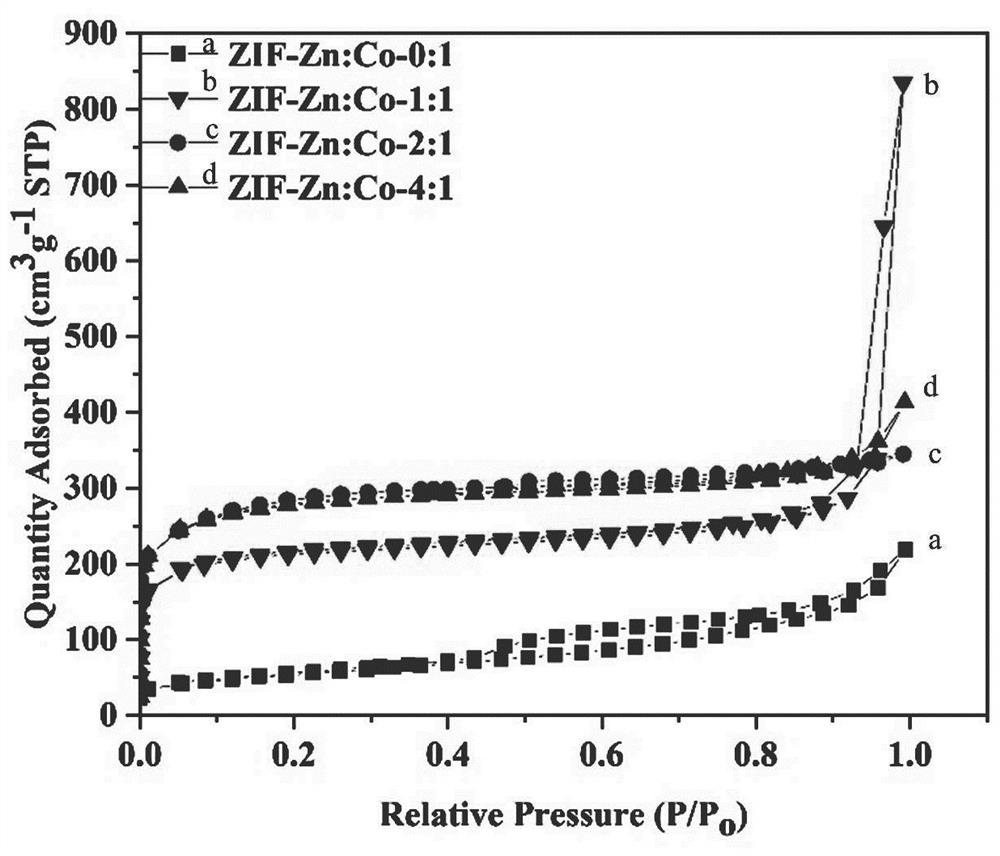

Embodiment 1

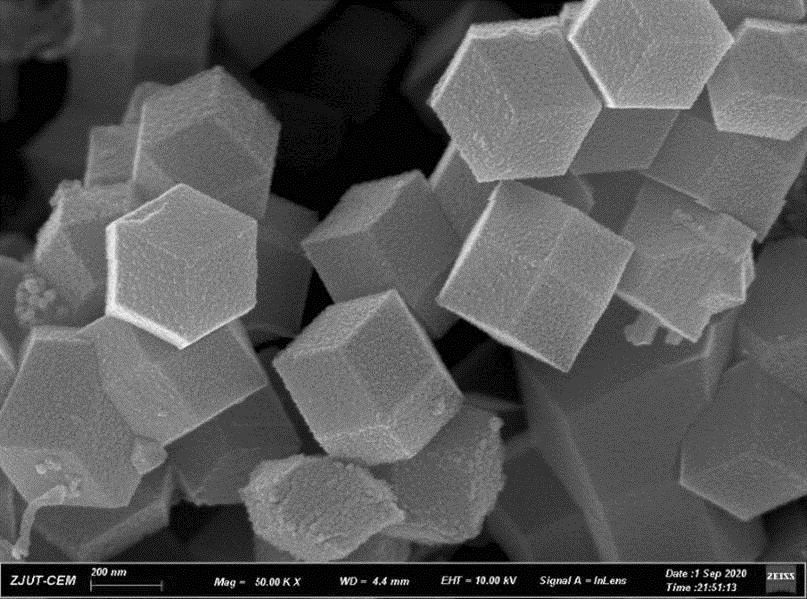

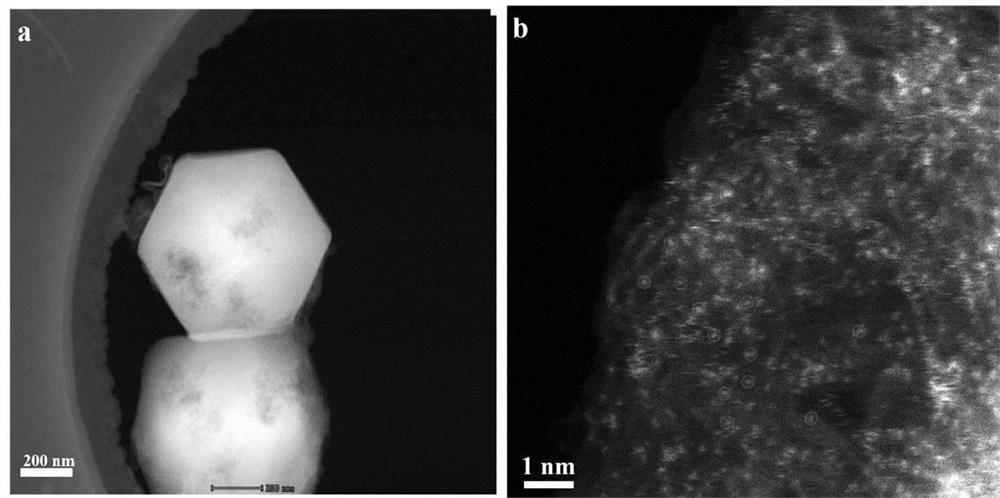

[0053] Embodiment 1 of the present invention provides a Co atom-doped polyhedral MOFs material and a preparation method thereof, comprising the following steps:

[0054] (1) At a room temperature of 25 °C, put zinc nitrate hexahydrate and cobalt nitrate hexahydrate in a molar ratio of 2:1 into methanol solution and stir for 24 hours. After the reaction, the product was centrifuged and dried to obtain the precursor powder;

[0055] (2) Put 5.5 g of dicyandiamide into a muffle furnace for calcination, raise the temperature to 550 ℃ at 2 ℃ / min, and roast at this temperature for 2 h to obtain g-C 3 N 4 powder;

[0056] (3) The precursor powder of step (1) and the g-C of step (2) 3 N 4 The powder was mixed evenly in a mortar at a mass ratio of 1:2, ground for 20 minutes, and then placed in a tube furnace for calcination at 900 °C (increased at 2 °C / min to 900 °C) for 3 h, and the calcination atmosphere was nitrogen to obtain ZIF-Zn :Co-2:1;

[0057] (4) Wash ZIF-Zn:Co-2:1 with...

Embodiment 2

[0059] Embodiment 2 of the present invention provides a Co atom-doped polyhedral MOFs material and a preparation method thereof, comprising the following steps:

[0060] (1) At room temperature of 28 °C, zinc nitrate hexahydrate and cobalt nitrate hexahydrate were put into methanol solution with a molar ratio of 4:1 and stirred for 22 hours. After the reaction, the product was centrifuged and dried to obtain the precursor powder;

[0061] (2) Put 5.5 g of dicyandiamide into a muffle furnace for calcination, raise the temperature to 520 ℃ at 2 ℃ / min, and roast at this temperature for 3 h to obtain g-C 3 N 4 powder;

[0062] (3) The precursor powder of step (1) and the g-C of step (2) 3 N 4 The powder was mixed evenly in a mortar at a mass ratio of 1:2, ground for 20 min, and then placed in a tube furnace for calcination at 850 °C (increased at 2 °C / min to 850 °C) for 4 h, and the calcination atmosphere was nitrogen to obtain ZIF-Zn :Co-4:1;

[0063] (4) Wash ZIF-Zn:Co-4:1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com