Preparation method and application of hydroxyapatite nanowire sintered porous ceramic beads

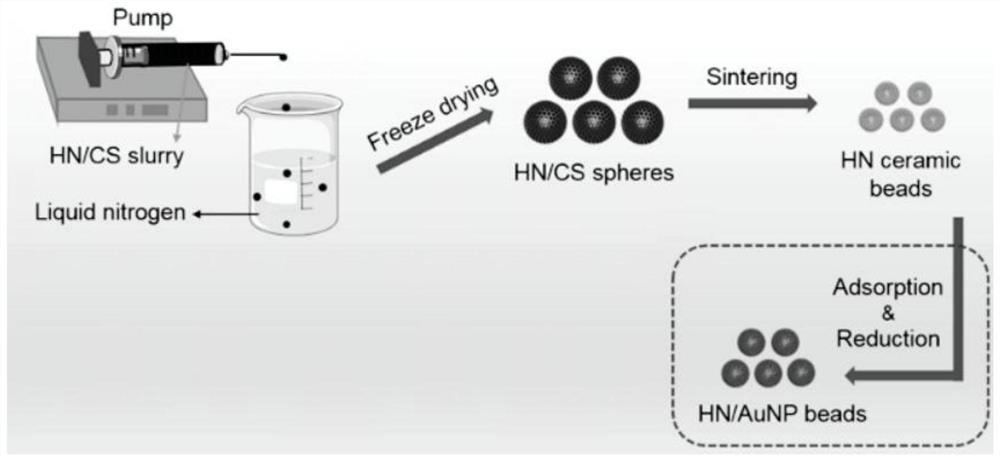

A technology of hydroxyapatite and porous ceramics, which is applied in the field of preparation of hydroxyapatite nanowire sintered porous ceramic beads and hydroxyapatite nanowire sintered porous ceramic beads, which can solve the problems of low recovery efficiency and small macroscopic size of the carrier, etc. problem, to achieve the effect of adjustable porosity, high activity, and good distribution of AuNPs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a porous ceramic microbead sintered with hydroxyapatite nanowires, and the anchor sites of the porous ceramic microbead are loaded with gold nanoparticles (AuNPs).

Embodiment 2

[0073] This embodiment provides a method for preparing porous ceramic microbeads sintered with hydroxyapatite nanowires. The specific preparation steps are:

[0074] S1, using a solvothermal method to synthesize hydroxyapatite nanowires (HN), specifically;

[0075] 1) 93.4g oleic acid, 135g water and 48g methanol were mixed uniformly to obtain mixture A;

[0076] 2) 10.5g sodium hydroxide was dissolved in 150mL water to obtain mixture B, 3.3g calcium chloride was dissolved in 150mL water to obtain mixture C, 7.3g anhydrous sodium dihydrogen phosphate was dissolved in 150mL water to obtain mixture D, Add mixture B, mixture C and mixture D to mixture A in turn to obtain a slurry, and the interval between each addition is 20 minutes;

[0077] 3) Pour the slurry into a 1L polytetrafluoroethylene autoclave and keep it at 180°C for 25h;

[0078] 4) The product is washed three times with ethanol and water respectively;

[0079] The preparation of S2, HN porous ceramic microbeads, ...

Embodiment 3

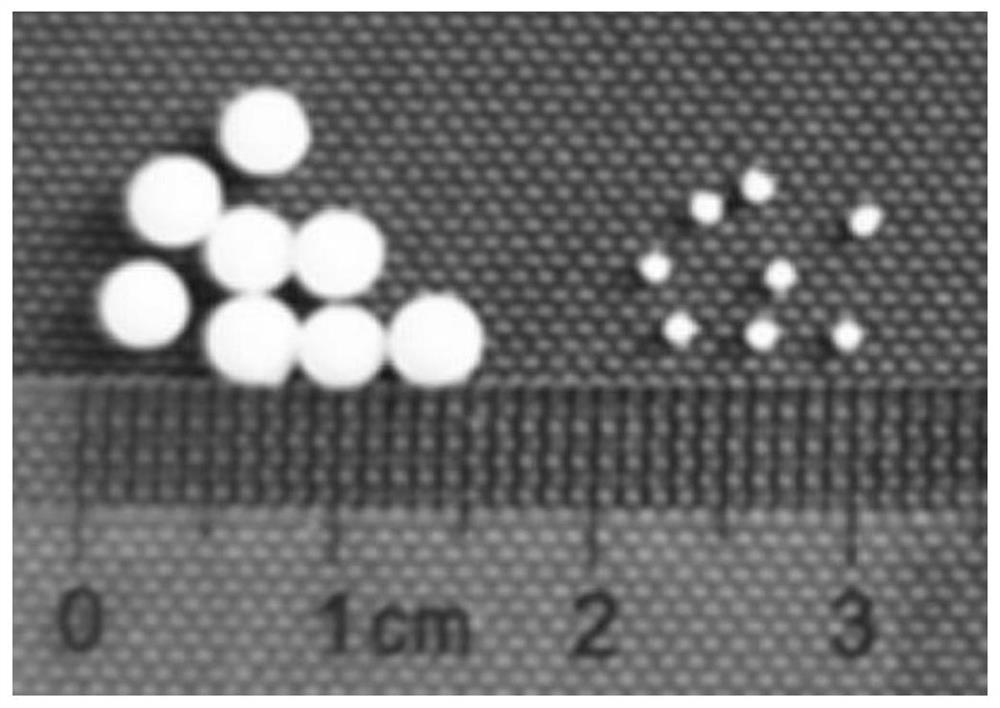

[0089] This example provides a method for preparing porous ceramic microbeads sintered with hydroxyapatite nanowires. The shrinkage product HN porous ceramic microbeads prepared has a HN concentration of 1.2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap