A kind of preparation method and application of polycarbonate low temperature toughening masterbatch with compatibilization function

A technology of polycarbonate and toughened masterbatch, which is applied in the field of preparation of polycarbonate low-temperature toughened masterbatch, which can solve the problems of harsh synthesis process conditions, etc., and achieve improved compatibilization effect, low glass transition temperature, and increased low temperature The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

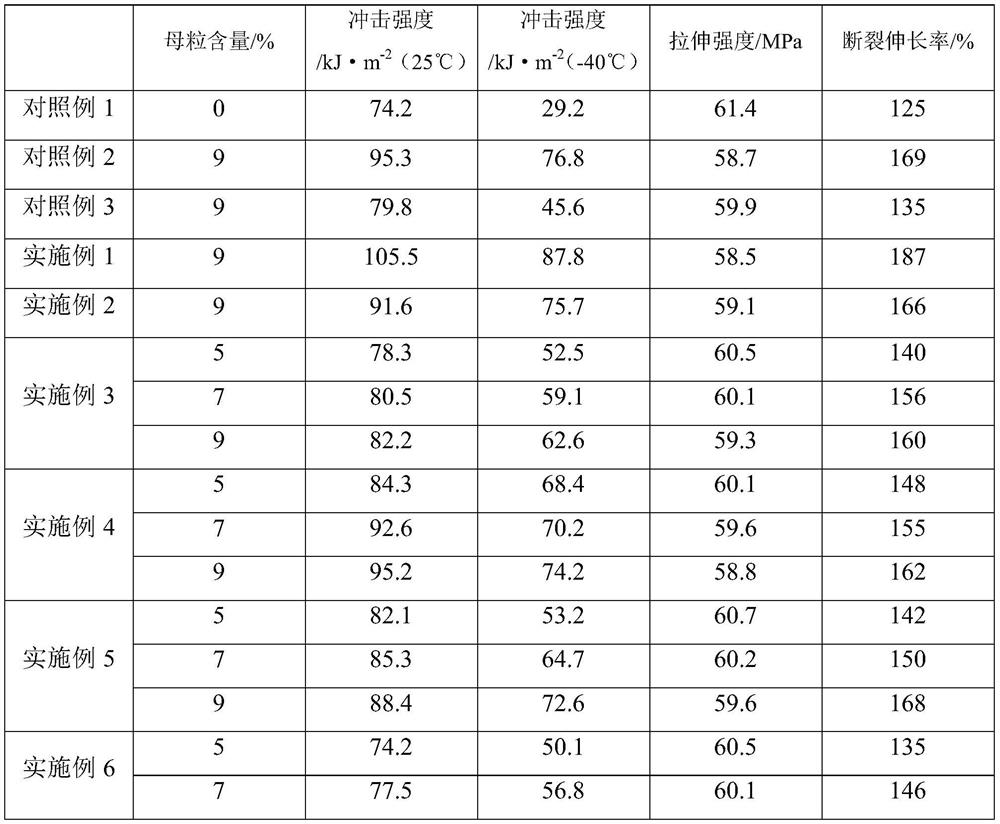

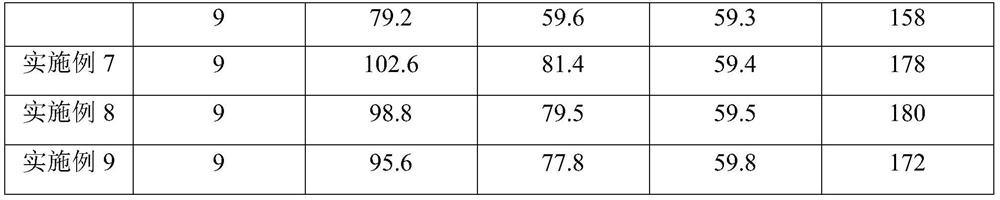

Examples

Embodiment 1

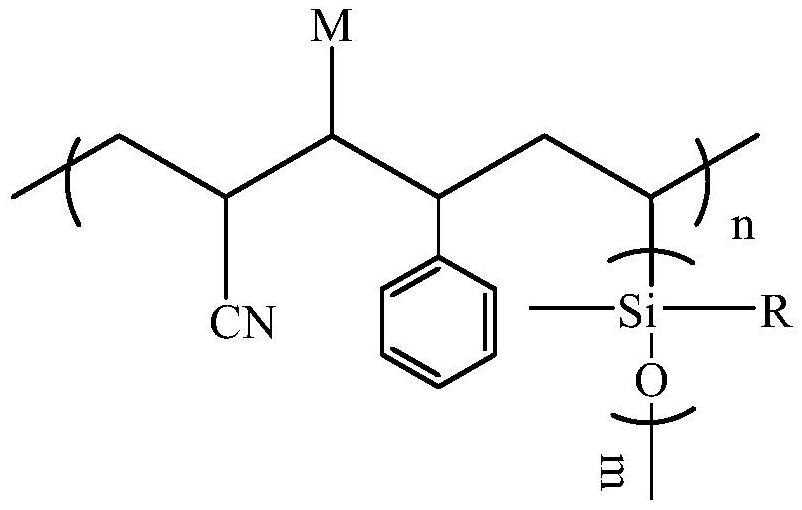

[0030] (1) Preparation of compatibilizer by emulsion polymerization: Mix methyl vinyl silicone oil, styrene, and acrylonitrile evenly, and record it as the oil phase, wherein the mass ratio of styrene, acrylonitrile, and methyl vinyl silicone oil is 3:1: 3. The molecular weight of methyl vinyl silicone oil is 20,000; in addition, stir the emulsifier sodium dodecylbenzenesulfonate and water at 75°C to fully emulsify, record it as the water phase, then mix the oil phase with the water phase, and continue Stir to form stable emulsion, then add initiator ammonium persulfate and carry out emulsion polymerization, wherein emulsifier sodium dodecylbenzene sulfonate is 5% of monomer total mass, initiator is 0.3% of monomer total mass, in After the reaction at 75°C, the emulsion was broken, and the solid product was filtered and washed, and then dried to constant weight to obtain a styrene-acrylonitrile-silicone oil terpolymer compatibilizer.

[0031] (2) Preparation of modified compat...

Embodiment 2

[0034] (1) Preparation of compatibilizer by emulsion polymerization: Mix methyl vinyl silicone oil, styrene, and acrylonitrile evenly, and record it as the oil phase, wherein the mass ratio of styrene, acrylonitrile, and methyl vinyl silicone oil is 3:1: 2. The molecular weight of methyl vinyl silicone oil is 40,000; in addition, the emulsifier compound emulsifier sodium dodecylbenzene sulfonate and polyethylene glycol octyl phenyl ether and water are stirred at 80°C to fully emulsify, which is recorded as water phase, then mix the oil phase with the water phase, and continue to stir until a stable emulsion is formed, then add initiator potassium persulfate to carry out emulsion polymerization, wherein the compound emulsifier is 4% of the total mass of the monomer, and the initiator is a single After the reaction at 80°C, the emulsification is broken, and the solid product is filtered and washed, and then dried to constant weight to obtain a styrene-acrylonitrile-silicone oil t...

Embodiment 3

[0038] (1) Preparation of compatibilizer by emulsion polymerization: Mix methyl vinyl silicone oil, styrene, and acrylonitrile evenly, and record it as the oil phase, wherein the mass ratio of styrene, acrylonitrile, and methyl vinyl silicone oil is 3:1: 1. The molecular weight of methyl vinyl silicone oil is 60,000; in addition, the emulsifier compound emulsifier of sodium lauryl sulfate and polyethylene glycol octyl phenyl ether is fully emulsified with water at 85°C, which is recorded as the water phase , then mix the oil phase with the water phase, and continue to stir until a stable emulsion is formed, then add the initiator ammonium persulfate to carry out emulsion polymerization, wherein the compound emulsifier is 3% of the total mass of the monomer, and the initiator is 3% of the total mass of the monomer After the reaction is completed at 85°C, the emulsification is broken, and the solid product is filtered and washed, and then dried to constant weight to obtain a styr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com