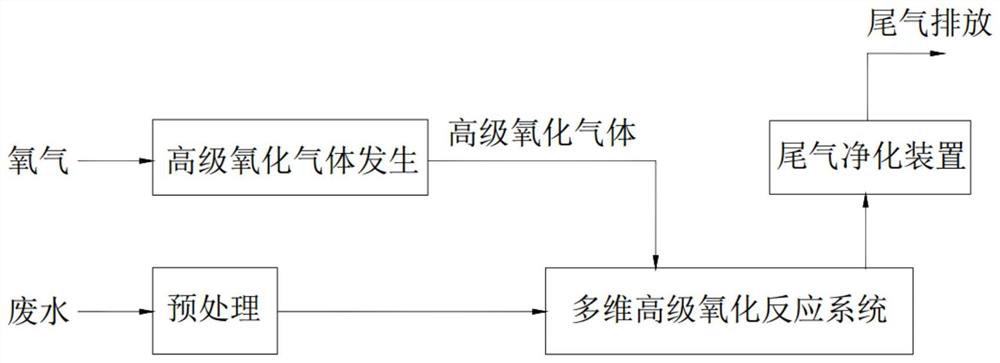

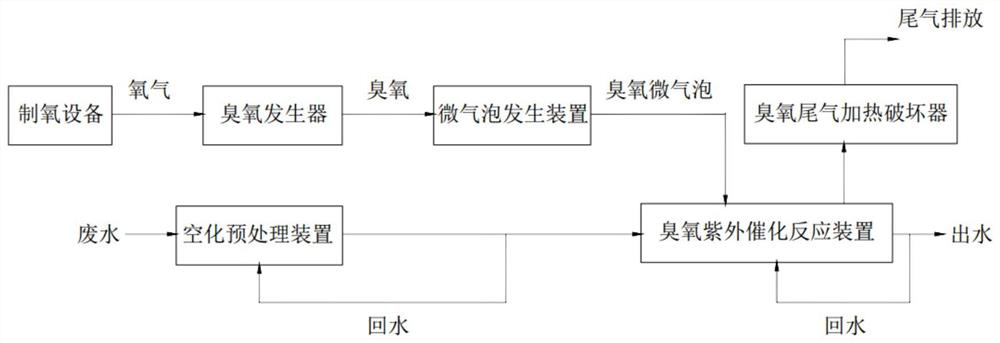

Multi-dimensional advanced oxidation organic wastewater advanced treatment method and system

An advanced oxidation and advanced treatment technology, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problems of low COD concentration requirements, increased operating costs, low energy of ultraviolet lamps, etc., to achieve The effect of saving degradation time, reducing operating costs and improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

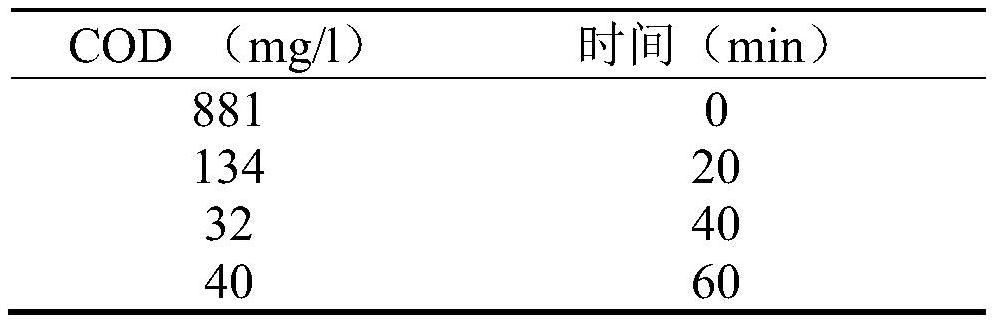

[0080] Coal gasification black water with a COD value of 881mg / L was treated by a multi-dimensional advanced oxidation organic wastewater treatment method.

[0081] Water flow 1.4m 3 / h, pH is 8.0, ozone intake volume is 0.14m 3 / h, using a gas-liquid mixing pump as a microbubble generator, a microwave electrodeless ultraviolet lamp, a wavelength of 185-254nm, a power of 2000W, a hydraulic cavitation number of 0.14, a cavitation pretreatment COD degradation rate of 25.2%, and an iron-based ozone catalyst of 50kg. The coal gasification black water circulation treatment with different residence time, the treatment capacity is 100L, the time and COD change values are shown in Table 1:

[0082] Table 1 Advanced Oxidation of Gasified Black Water

[0083]

Embodiment 2

[0084] Embodiment 2, multi-dimensional advanced oxidation and ozone / ultraviolet combined use comparison

[0085] In this example, the effect of multi-dimensional advanced oxidation combined with ozone ultraviolet is discussed, in order to determine the relative ability of multi-dimensional advanced oxidation to reduce COD value. The Fischer-Tropsch synthesis tower water is used, and its composition is shown in Table 2. It can be seen that the Fischer-Tropsch tower water is mainly composed of small molecular acids, the most important being acetic acid, which is relatively difficult to remove.

[0086] Table 2 Composition of Fischer-Tropsch kettle water

[0087]

[0088] The COD value of Fischer Tower kettle water is 14340mg / L, pH is 2.3, and the water flow rate of multi-dimensional advanced oxidation sewage treatment is 1.4m 3 / h, ozone intake volume 0.14m 3 / h, microwave electrodeless ultraviolet lamp, wavelength 185-254nm, power 800W, hydraulic cavitation number 0.2, cav...

Embodiment 3

[0093] The multi-dimensional advanced oxidation organic wastewater treatment method is used to treat phenol solution, the purpose is to simulate phenol-containing wastewater, the COD value of phenol solution is 1062mg / L, and the water flow rate of multi-dimensional advanced oxidation wastewater treatment is 1.4m 3 / h, the gas-liquid mixing pump is used as the microbubble generator, the gas-liquid ratio is 0.1, and the ozone intake volume is 0.14m 3 / h, microwave electrodeless ultraviolet lamp, wavelength 185 ~ 254nm, power 1200W, hydraulic cavitation number 0.16, iron-based ozone catalyst 10kg, hydraulic cavitation degradation rate 42.3%, cyclic treatment of 20L phenol solution, the treatment effect is shown in Table 4.

[0094] Table 4 Advanced oxidation effect of phenolic wastewater

[0095]

[0096] It can be seen from the data in Table 4 that the multidimensional advanced oxidation organic wastewater treatment method has a good degradation efficiency for phenol-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com