Stainless steel chromium-free passivator and surface treatment method

A chromium-free passivator and surface treatment technology, applied in the coating process of metal materials, etc., can solve problems such as poor corrosion resistance, surface corrosion and oxidation, and failure to meet the salt resistance requirements of stainless steel, so as to improve corrosion resistance, Improved corrosion resistance and short passivation treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

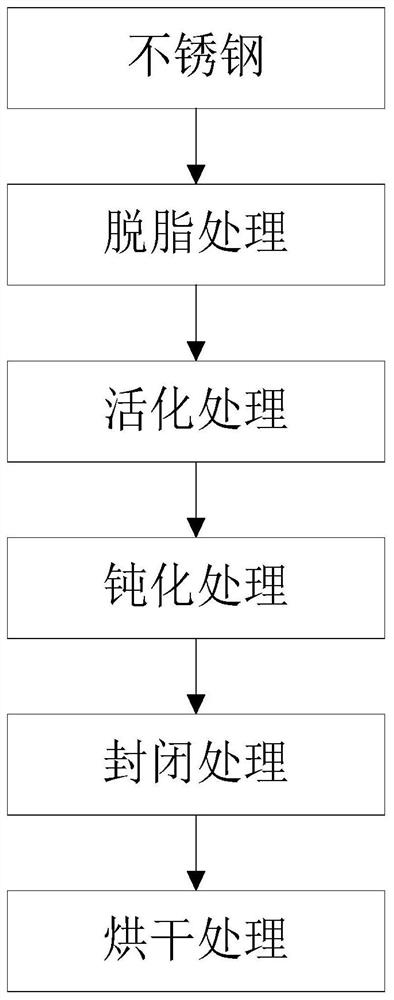

Method used

Image

Examples

preparation example Construction

[0035] Modified Nano TiO 2 Preparation of:

[0036] Add 0.1-0.5g of nano-titanium dioxide into 100mL Tris-HCL buffer solution (pH=8.5), disperse ultrasonically at 500-800W for 30-45min, continue to add 0.1-0.5g of dopamine hydrochloride, and stir the reaction at 40-50°C for 6- 8 hours, centrifugal separation, washing the solid product three times with water and ethanol respectively, and drying in vacuum at 35-40° C. for 12-24 hours to obtain polydopamine-modified nano-titanium dioxide.

Embodiment 1

[0038] Degreasing treatment: immerse 304 stainless steel workpiece in degreasing agent (sodium hydroxide 10g / L, sodium carbonate 20g / L, trisodium phosphate 5g / L, sodium metasilicate pentahydrate 1.25g / L, OP-10 emulsifier 1g / L , sodium dodecylbenzenesulfonate 2g / L, and the balance is water), soaking treatment at a temperature of 60°C for 6 minutes, and then entering activation treatment after washing with water;

[0039] Activation treatment: immerse the stainless steel workpiece in the activator (50% sulfuric acid 50-100g / L, 50% hydrogen peroxide 25-50g / L, anhydrous ethanol 20mL / L, the balance is water), soak at 30-50°C for 30 ~60s, enter passivation treatment after washing;

[0040] Passivation treatment: immerse 304 stainless steel workpiece in chromium-free passivation agent (45% fluorotitanic acid 3g / L, 68% nitric acid 300g / L, sodium metavanadate 20g / L, 50% nickel nitrate 10g / L, modified nano Titanium dioxide 3g / L, the balance is water), soaking treatment at 55-65°C for 1...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is that the stainless steel workpiece processed is a 316 stainless steel workpiece, wherein the chromium-free passivating agent used for passivation treatment includes components of 45% fluorotitanic acid 5g / L, 68% nitric acid 350g / L L, sodium metavanadate 10g / L, 50% nickel nitrate 20g / L, modified nano titanium dioxide 5g / L, and the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com