Iron monatomic catalyst, preparation method thereof and application thereof in water electrolysis oxygen evolution reaction

A technology for oxygen evolution reaction and catalyst, which is applied in the direction of electrolysis process, electrolysis components, electrodes, etc., and can solve the problems of controllable adjustment of electronic structure without realizing single atom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

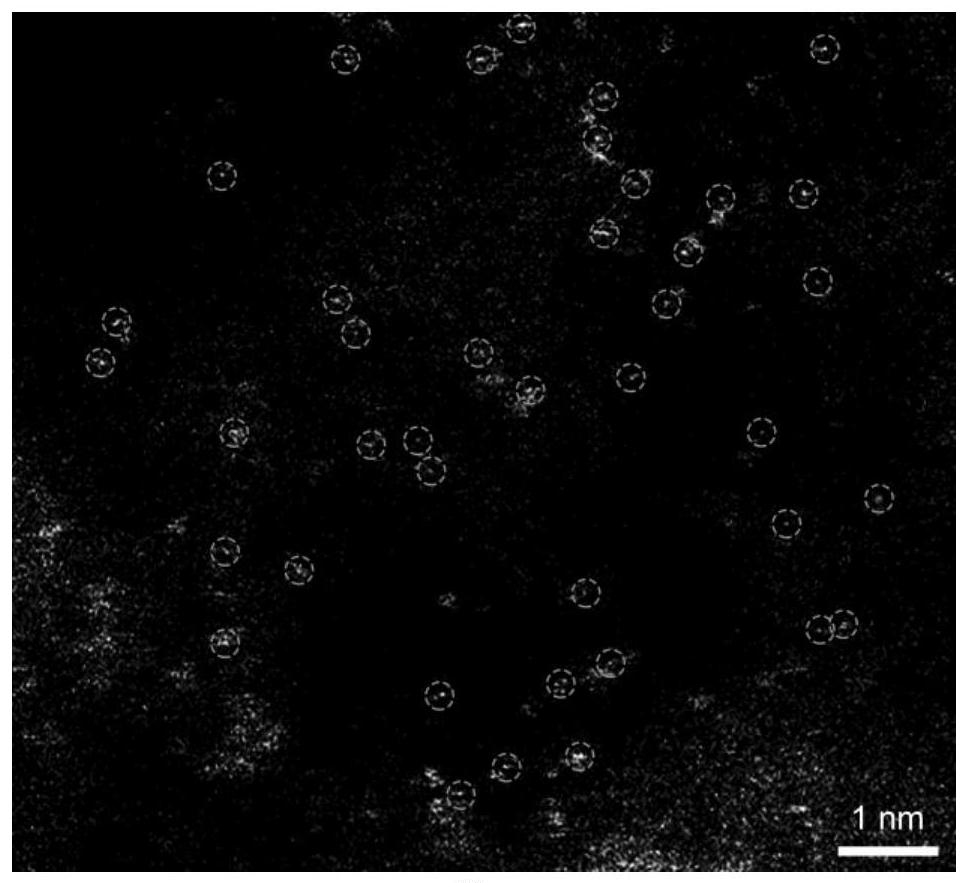

[0038] The present invention provides a kind of Fe described in above-mentioned technical scheme 1 (OH) x The preparation method of / P-C single-atom catalyst comprises the following steps:

[0039] In the electrolyte solution containing iron salts, the three-electrode system is used for electrochemical deposition, and the porous carbon P-C is used as the working electrode, and the electrochemical deposition is carried out for 4 to 6 times at a voltage of 1.3-1.8V and a scan rate of 5mV / s. Atoms are monodispersely and uniformly deposited onto porous carbon P-C to give Fe 1 (OH) x / P-C single atom catalyst.

[0040]In the present invention, the iron salt is preferably ferric chloride. Potassium hydroxide and water are also included in the electrolyte solution; the mass of the potassium hydroxide and the volume ratio of water are (55~57) mg:(0.9~1.1) mL; the potassium hydroxide and ferric chloride The mass ratio is 55~57:0.01~0.02.

[0041] In the present invention, the por...

Embodiment 1

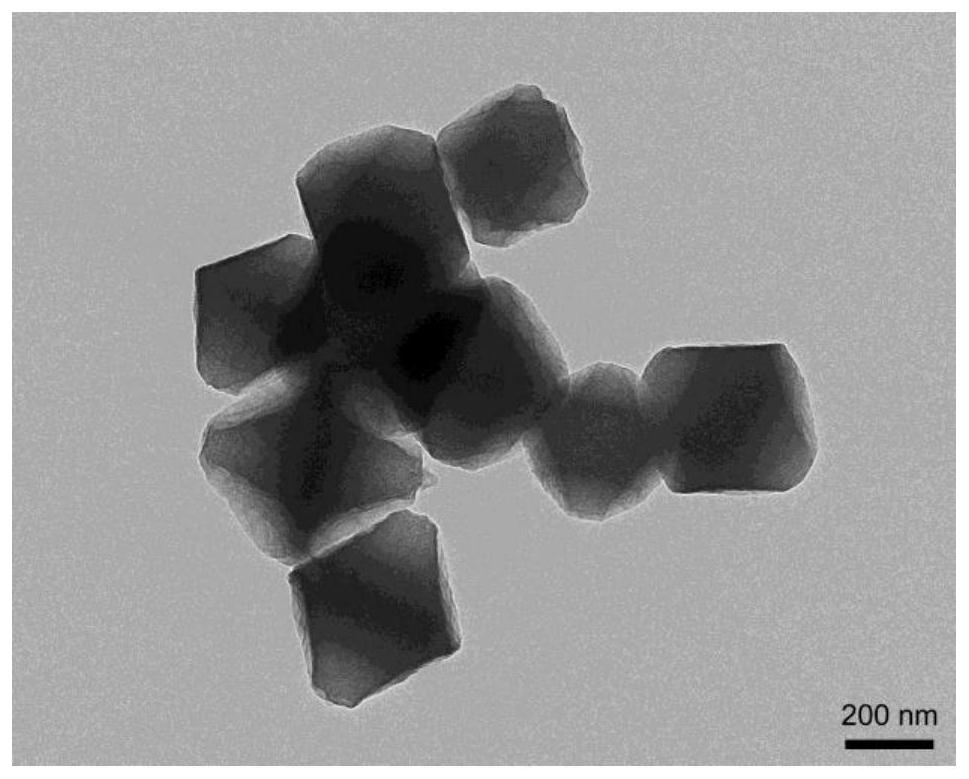

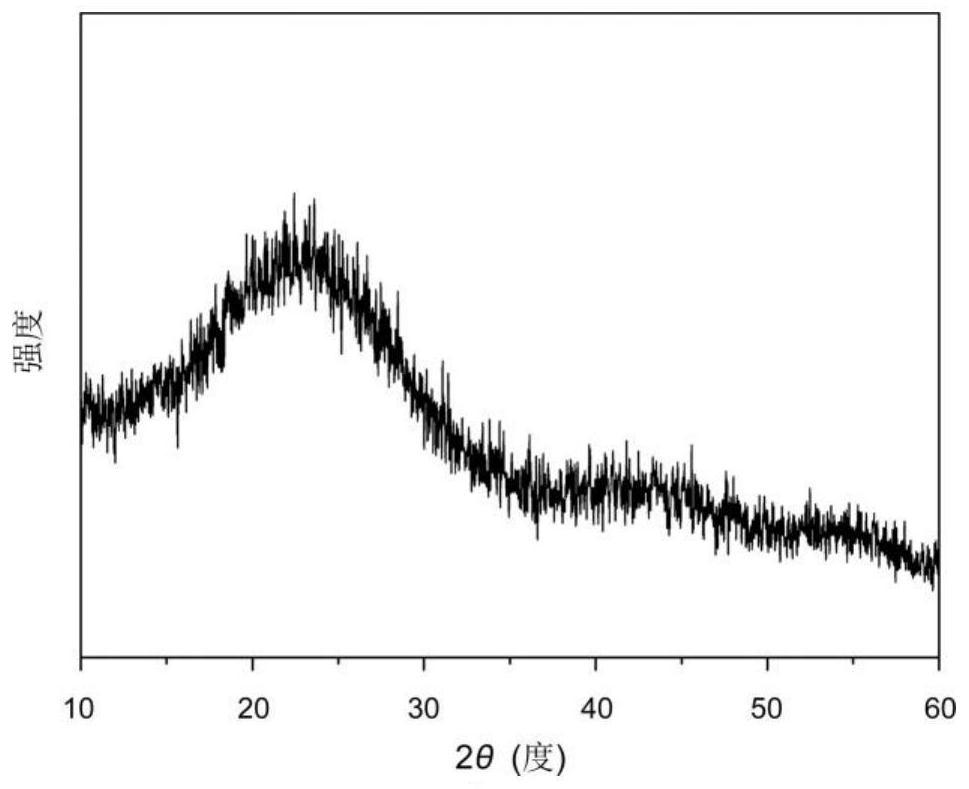

[0057] (1) Preparation of porous carbon P-C:

[0058] Mix 10.5mg of zirconium tetrachloride, 7.5mg of 2-hydroxyterephthalic acid, 10mL of dimethylformamide, and 1.2mL of acetic acid at room temperature, stir evenly and then sonicate for 30min; then react the liquid at 120°C for 24h, After cooling to room temperature, the obtained product was separated with a centrifuge, and washed three times with a mixture of dimethylformamide and ethanol at a volume ratio of 1:1; then the product was vacuum-dried at 60°C for 12 hours; then The dried white powder was calcined in a tube furnace under the protection of nitrogen, the heating rate was 5°C / min, and the calcining temperature was 700°C. After reaching the calcining temperature, it was kept for 3h, and the nitrogen flow rate was 50sccm; after natural cooling to room temperature, the The obtained black powder was uniformly dispersed into a mixture of 15 mL deionized water and 0.1 mol hydrofluoric acid, and treated under magnetic stirr...

Embodiment 2

[0062] (1) Preparation of porous carbon P-C:

[0063] Mix 11.0mg of zirconium tetrachloride, 8.0mg of 2-hydroxyterephthalic acid, 10.0mL of dimethylformamide, and 1.5mL of acetic acid at room temperature, stir evenly and then sonicate for 45min; then react the liquid at 130°C for 22h , after cooling to room temperature, the obtained product was separated with a centrifuge, and washed 4 times with a mixture of dimethylformamide and ethanol with a volume ratio of 0.8:1.2; then the product was vacuum-dried at 80°C for 12h; then The dried white powder was calcined in a tube furnace under the protection of nitrogen, the heating rate was 5°C / min, the calcining temperature was 720°C, and kept for 3 hours after reaching the calcining temperature, and the nitrogen flow rate was 100 sccm; after cooling to room temperature naturally, Evenly disperse the obtained black powder into a mixture of 20mL deionized water and 0.2mol hydrofluoric acid, and treat it under magnetic stirring for 3h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com