Electrochemical sensing method for rutin detection

A sensing method and electrochemical technology, applied in the field of electrochemical sensing, can solve the problems of high price, lack of modified materials, high detection limit, etc., and achieve the effect of wide detection concentration range, strong reproducibility, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

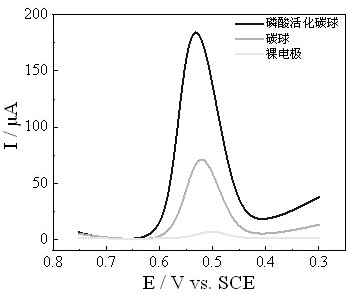

[0027] An electrochemical sensing method for rutin detection, comprising the following steps:

[0028] Step 1: Preparation of modified materials

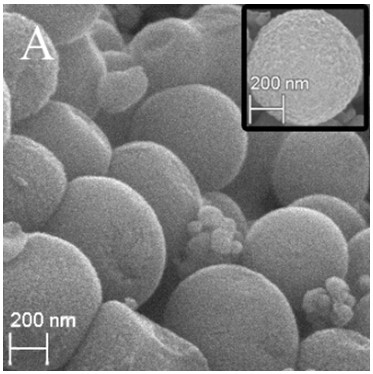

[0029] Dissolve 2g of β-cyclodextrin in 20mL of ultrapure water, and after ultrasonic dissolution, transfer the resulting solution to an 80mL polytetrafluoroethylene-lined stainless steel autoclave, and perform hydrothermal treatment at 433K for 24h. After naturally cooling to room temperature, the obtained brown mixture was filtered to remove impurities, and then the precursor was obtained by repeated high-speed centrifugation with ultrapure water and ethanol, and dried in a 343K oven. Then calcined at 1073K for 4h at 278K / min in a tube furnace under the protection of N2 to obtain carbon spheres.

[0030] Step 2: Preparation of modified electrodes

[0031] Weigh 1 mg of the prepared carbon spheres and disperse them in 1 mL of ultrapure water, and ultrasonicate for 10 minutes to form a uniformly dispersed and stable mixed solution...

Embodiment 2

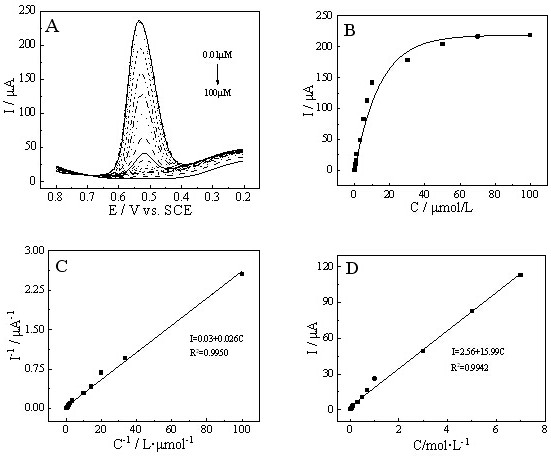

[0035] An electrochemical sensing method for rutin detection, comprising the following steps:

[0036] Step 1: Preparation of modified materials

[0037] Dissolve 2g of β-cyclodextrin in 20mL of ultrapure water, and after ultrasonic dissolution, transfer the resulting solution to an 80mL polytetrafluoroethylene-lined stainless steel autoclave, and perform hydrothermal treatment at 433K for 24h. After naturally cooling to room temperature, the obtained brown mixture was filtered to remove impurities, and then the precursor was obtained by repeated high-speed centrifugation with ultrapure water and ethanol, and dried in a 343K oven. Phosphoric acid activation treatment afterwards (mass ratio is phosphoric acid (85%): precursor=4:1), put into oven and dry at 373K, finally in the tube furnace under N2 protection with 1073K calcining 4h, 278K / min, get Phosphorus-doped hierarchically porous carbon spheres.

[0038] Step 2: Preparation of modified electrodes

[0039] Weigh 1mg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com