Anti-freezing hydrogel as well as preparation method and application thereof

A gel and freezing water technology, applied in the field of hydrogel, can solve the problems of long low temperature retention time, inelasticity of hydrogel, short thawing time, etc., and achieve the effect of good flexibility and stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

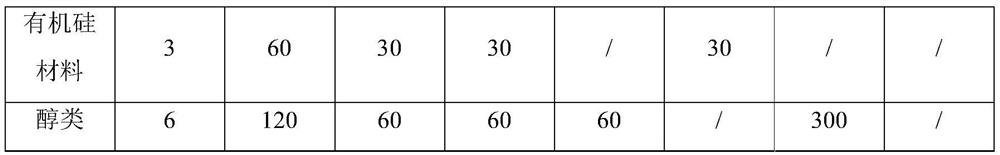

[0055] Dissolve 6 g of nanometer laponite (Laponite) in 565.8 g of water and stir for a period of time to form a uniform transparent solution. Weigh 18 g of polymerized monomer acrylamide, 0.3 g of initiator ammonium persulfate, and 0.6 g of chain transfer agent dodecyl mercaptan. g is dissolved in this solution after stirring to form a solution, which is component A; the polymerization accelerator N,N,N,N-tetramethylethylenediamine 0.3g and the silane coupling agent γ-methacryloyloxy Add 3 g of propyltrimethoxysilane to 6 g of ethanol to form a solution, which is component B. Blend component A and component B to form a solution, quickly pour it into a plastic sealing bag to discharge the air and seal it, and leave it to stand at room temperature for 30 minutes to obtain a gel.

[0056] Put the sealed bag in the freezer of the refrigerator, freeze it overnight at minus 15°C, take it out, and measure the tensile length, low temperature retention time, and crimp performance.

Embodiment 2

[0058] Take 60g of montmorillonite and dissolve it in 162g of water to form a uniform transparent solution after stirring for a period of time, weigh 180g of polymerized monomer 2-acrylamide-2-methylpropanesulfonate, 6g of initiator potassium persulfate, and chain transfer agent mercaptoethanol 6g is dissolved in this solution after stirring to form a solution, which is component A; 6g of polymerization accelerator triethanolamine and 60g of silane coupling agent vinyltrimethoxysilane are added to 120g of propylene glycol to form a solution, and this solution is component B . Blend component A and component B to form a solution, quickly pour it into a plastic sealing bag to discharge the air and seal it, and leave it to stand at room temperature for 30 minutes to obtain a gel.

[0059] Put the sealed bag in the freezer of the refrigerator, freeze it overnight at minus 15°C, take it out, and measure the tensile length, low temperature retention time, and crimp performance.

Embodiment 3

[0061] Take 18g of nanometer laponite (Laponite) and dissolve it in 428.4g of water to form a uniform transparent solution after stirring for a period of time, weigh 60g of polymerized monomer acrylic acid, 1g of initiator azobisisobutylamidine hydrochloride, and chain transfer agent thioglycolic acid 2g is dissolved in this solution after stirring to form a solution, which is component A; 0.6g of polymerization accelerator triethanolamine and 30g of silane coupling agent vinyltrimethoxysilane are added to 60g of ethylene glycol to form a solution, this solution is Component B. Blend component A and component B to form a solution, quickly pour it into a plastic sealing bag to discharge the air and seal it, and leave it to stand at room temperature for 30 minutes to obtain a gel.

[0062] Put the sealed bag in the freezer of the refrigerator, freeze it overnight at minus 15°C, take it out, and measure the tensile length, low temperature retention time, and crimp performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com