A kind of mxene base catalyst and its preparation method and application

A technology of catalyst and dispersion liquid, which is applied in the field of MXene-based catalyst and its preparation, and can solve the problems of poor catalyst selectivity, environmental pollution, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

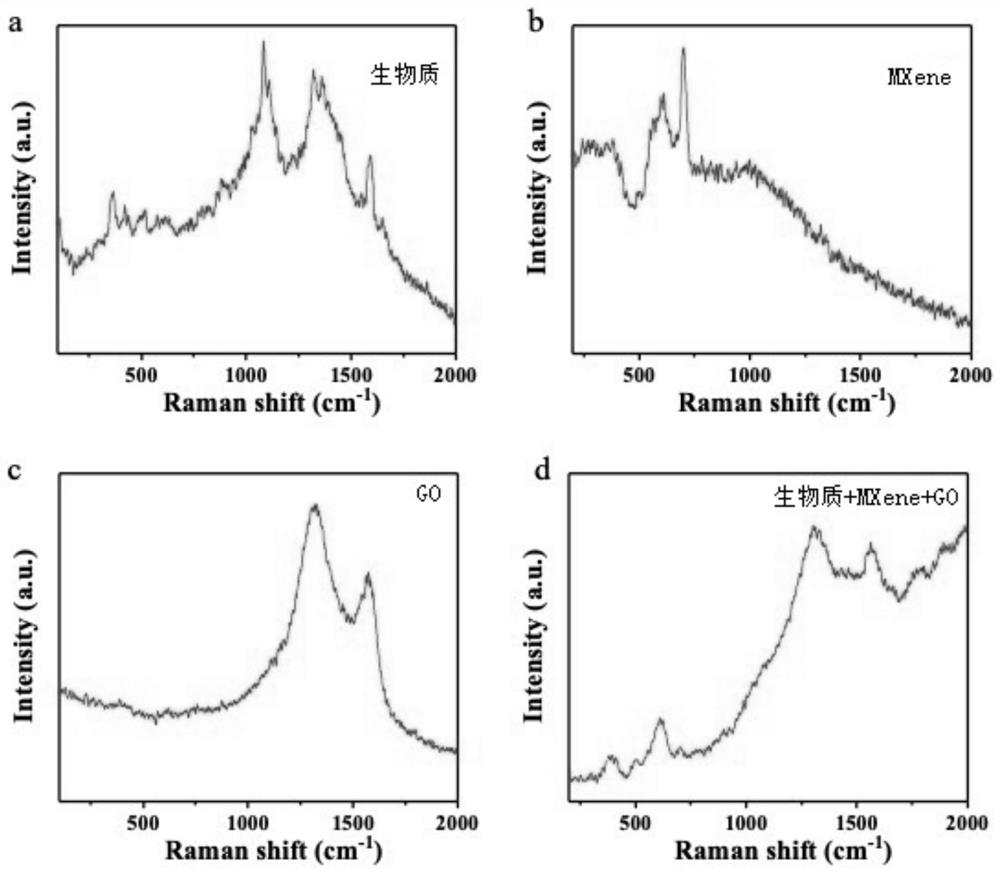

Image

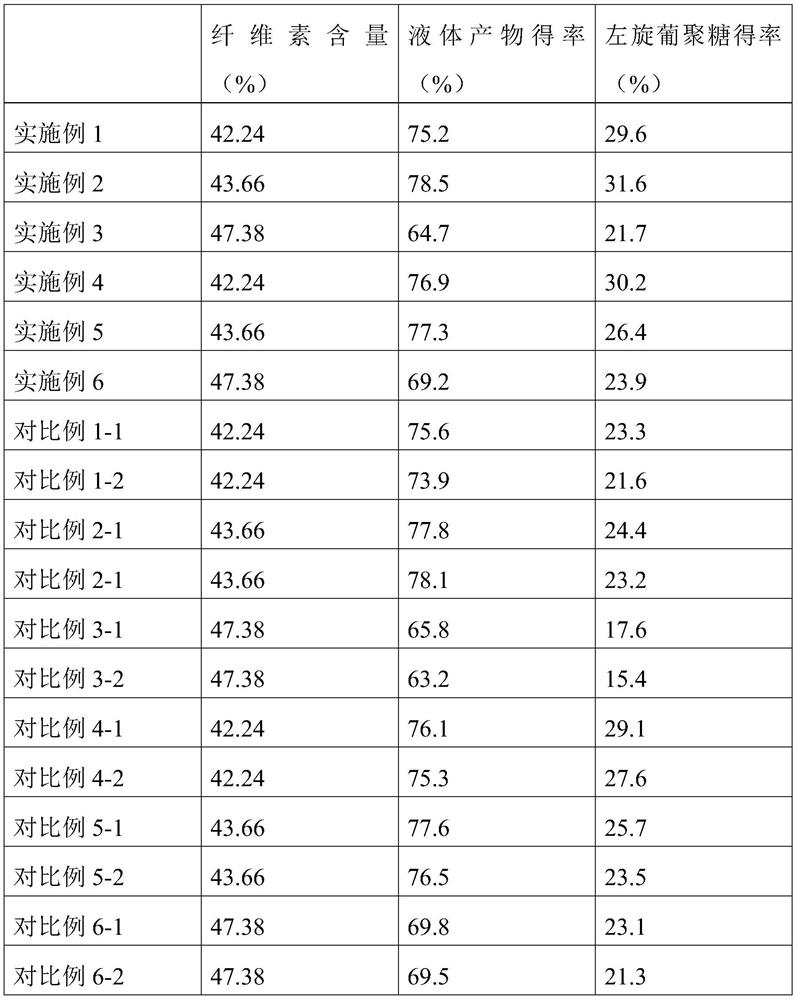

Examples

preparation example Construction

[0024] The preparation method of described MXene-based catalyst, comprises the following steps:

[0025] Add the graphene oxide dispersion liquid into the MXene dispersion liquid, mix uniformly to obtain the mixed liquid A, and freeze-dry the above mixed liquid A for 20-100 h to obtain the MXene-based catalyst with high selectivity.

[0026] The concentration of the MXene dispersion is 0.5-10mg / mL, the concentration of the graphene oxide dispersion is 0.5-10mg / mL, and the volume ratio of the MXene dispersion and the graphene oxide dispersion is (1-10):1 . The graphene oxide dispersion liquid is an ordinary single-layer graphene oxide dispersion liquid.

[0027] The preparation method of described MXene dispersion liquid comprises the following steps:

[0028] Step 1: Disperse lithium fluoride in hydrochloric acid, and fully stir with a magnetic stirrer at 25-70°C for 1-10min at 200-2400rpm to obtain a mixed solution B; the concentration of the hydrochloric acid is 6-12M, and...

Embodiment 1

[0032] MXene (Ti 3 C 2 T x ) The preparation method of dispersion liquid, comprises the following steps:

[0033] Step 1: Add 40mL of 9M hydrochloric acid into a plastic bottle, then disperse 3.2g of lithium fluoride in hydrochloric acid, and fully stir at room temperature with a magnetic stirrer at a speed of 1000rpm for 5min to obtain a mixed solution B;

[0034] Step 2: Set MAX(Ti 3 AlC 2 ) phase was gradually and slowly added to the mixed solution B, followed by a magnetic stirring reaction at a speed of 1000 rpm at 35°C for 36 hours to obtain a mixed solution C; the volume mass ratio of MAX to the mixed solution B was 2g:40mL;

[0035] Step 3: Centrifuge the precipitate of the mixture C with distilled water repeatedly until the pH of the supernatant is neutral, then dilute the obtained substrate with 100mL of water and ultrasonicate for 30min in a nitrogen ice bath environment with a power of 200W. Finally, the diluted solution was centrifuged at 4,000 r / min for 10 m...

Embodiment 2

[0043] MXene (Ti3 C 2 T x ) The preparation method of dispersion liquid, comprises the following steps:

[0044] Step 1: Add 40mL of 9M hydrochloric acid into a plastic bottle, then disperse 3.2g of lithium fluoride in hydrochloric acid, and fully stir with a magnetic stirrer at a speed of 200rpm at room temperature for 5min to obtain a mixed solution B;

[0045] Step 2: Set MAX(Ti 3 AlC 2 ) phase was gradually and slowly added to the mixed solution B, followed by a magnetic stirring reaction at a speed of 300 rpm at 35°C for 36 hours to obtain a mixed solution C; the volume mass ratio of MAX to the mixed solution B was 2g:40mL;

[0046] Step 3: Centrifuge the centrifuged precipitate of the mixture C with distilled water until its pH is neutral, then dilute the obtained product with 100mL of water and ultrasonicate for 5min in a nitrogen ice bath environment with a power of 1200W, and finally dilute the diluted The resulting solution was centrifuged at 4000 r / min for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com