Multi-quaternary ammonium side long-chain type polysulfone anion exchange membrane and preparation method thereof

An anion-exchange membrane and multi-quaternary ammonium technology, which is applied in the field of preparation of multi-quaternary ammonium side long-chain polysulfone anion-exchange membranes, can solve problems such as mechanical property degradation, excessive hydrophilicity of polymer membranes, and severe membrane swelling, and achieve Good dimensional stability, improved hydroxide conductivity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the preparation method of the multi-quaternary ammonium side long-chain polysulfone anion exchange membrane, step (3) specifically includes: polymers with different branching degrees of side chains are dissolved in the solvent N-methylpyrrolidone, and after being completely dissolved to obtain The film-forming liquid contains about 3% by weight of the polymer in the film-forming liquid. The film-forming solution is cast into a film by a casting method to obtain a side long-chain polysulfone anion exchange membrane containing multiple quaternary ammonium functional groups.

[0028] Preferably, the preparation method of the side long-chain monomer with multiple quaternary ammonium functional groups in step (3) specifically includes: as shown in formula III, stirring and mixing 1,6-dibromohexane and anhydrous diethyl ether as a solvent , drop trimethylamine alcohol solution at 0°C, and the final mixed solution was reacted at room temperature for 36 hours to obtain a mon...

Embodiment 1

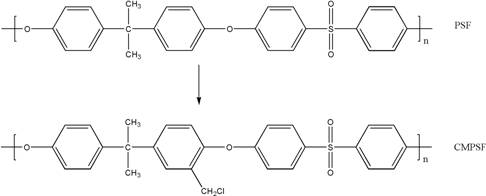

[0032] Example 1, preparation of chloromethylated polysulfone (CMPSF):

[0033] (1) Weigh 2g polysulfone (PSF) into a three-neck flask, add 20ml 1,2-dichloroethane, stir and dissolve at room temperature, so that it is completely dissolved into a uniform solution;

[0034] (2) Add 0.2g of zinc powder and 0.8ml of trifluoroacetic acid to the homogeneous solution in the flask, and continue stirring for 15 minutes;

[0035] (3) Slowly add 4ml of chloromethyl ether dropwise to the mixed solution in the flask. After the dropwise addition is completed, start to heat up to 30°C, and react at this temperature for 2.5 hours, 3 hours and 5 hours respectively;

[0036] (4) After the reaction, a light yellow solution was obtained, cooled to room temperature, then poured into methanol solution to precipitate a white polymer, cut it into pieces, continued to filter and wash with methanol solution for three times, and filtered and washed with deionized water for two times. Second-rate;

[0...

Embodiment 2

[0039] Embodiment 2, the preparation of the monomer (Br-QA) that has a quaternary ammonium functional group:

[0040] (1) Pour 22ml of 1,6-dibromohexane and 25ml of anhydrous ether into a three-neck flask and stir at room temperature, then place the mixture in an ice bath and cool it at close to 0°C;

[0041] (2) After the cooling is completed, slowly add 6ml trimethylamine alcohol solution dropwise under the stirring state, after the dropwise addition is completed, continue to stir at 0°C for 15 minutes;

[0042] (3) The mixed solution was raised to room temperature (25°C), and stirred and reacted at room temperature for 36 hours;

[0043] (4) After the reaction, a white solid product was obtained, which was washed twice with anhydrous ether;

[0044] (5) Dry the washed white solid in a vacuum oven at 40°C for 24 hours;

[0045] (6) Finally, a monomer with a quaternary ammonium functional group, namely Br-QA, was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com