Preparation method of low-cost mullite fiber

A mullite fiber, low-cost technology, applied in the field of low-cost mullite fiber preparation, can solve the problems of dangerous hydrogen, lack of spinnability, and lack of spinnability of silica-alumina sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

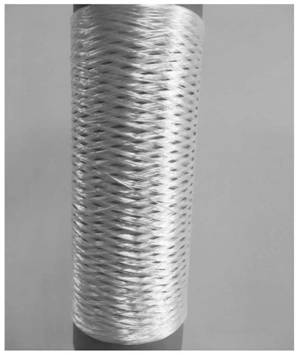

Image

Examples

Embodiment 1

[0036] Add formic acid and acetic acid into distilled water at 50°C, stir and mix well before adding aluminum hydroxide powder. The molar ratio of aluminum hydroxide to formic acid and acetic acid is 1:1, and the molar ratio of aluminum hydroxide to the formic acid added for the second time is 1:0.5. Afterwards, the mixture solution was concentrated at 100° C., continuously stirred and condensed and refluxed, at a temperature of 40° C., and a vacuum of 0.09 MPa to remove the carboxylic acid, and reacted for 10 hours to prepare a transparent aluminum carboxylate solution; the liquid two Silicon oxide and formic acid were mixed at a molar ratio of 1:1, and the precipitate was filtered after ultrasonic dispersion for 30 minutes; lactic acid, glycerin, polyvinyl butyral, and polyvinyl alcohol were added to the clarified liquid for mixing;

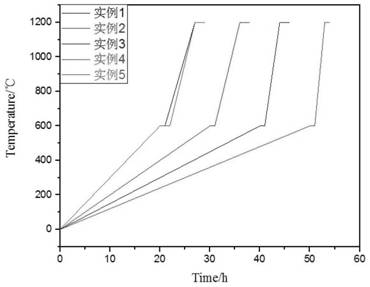

[0037] Depend on figure 1 As can be seen from the NMR spectrum of the aluminum carboxylate solution: the prepared aluminum carboxylate solut...

Embodiment 2

[0040] Add propionic acid and oxalic acid into distilled water at 65°C, stir and mix well before adding aluminum hydroxide powder. The molar ratio of aluminum hydroxide to propionic acid and oxalic acid is 1:2, and the molar ratio of aluminum hydroxide to acetic acid is 1:1. Afterwards, the mixture solution was concentrated at 150° C., continuously stirred and condensed and refluxed, at a temperature of 70° C., and a vacuum of 0.09 MPa to remove carboxylic acid, and reacted for 20 hours to prepare a transparent aluminum carboxylate solution; figure 1 The aluminum carboxylate solution NMR spectra can be seen: the prepared aluminum carboxylate solution exists in the form of multimer Al8-18OX12-27. Depend on image 3 The infrared test pattern of the aluminum carboxylate solution shows that the functional groups of its multimer exist in the form of groups such as (HCOO) (RCOO) (OOC-COOH).

[0041]Then mix silica sol and acetic acid at a molar ratio of 1:2, ultrasonically disper...

Embodiment 3

[0043] Add malonic acid and citric acid into distilled water at 80°C, stir and mix well, and then add aluminum hydroxide powder. The molar ratio of aluminum hydroxide to propionic acid and oxalic acid is 1:3, and the molar ratio of aluminum hydroxide to acetic acid is 1:2. Afterwards, the mixture solution was reacted for 30 hours at 200° C. under continuous stirring and condensing and reflux conditions to prepare a transparent aluminum carboxylate solution; by figure 1 The aluminum carboxylate solution NMR spectra can be seen: the prepared aluminum carboxylate solution exists in the form of multimer Al8-18OX12-27. Depend on image 3 The infrared test pattern of the aluminum carboxylate solution shows that the functional groups of its multimer exist in the form of groups such as (HCOO) (RCOO) (OOC-COOH).

[0044] Then liquid silicon dioxide and propionic acid were mixed at a molar ratio of 1:3, and the precipitate was filtered after ultrasonic dispersion for 60 minutes; poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com