Preparation method of xanthic acid alkyl hydroxamic acid ester

A technology of xanthate alkyl hydroxamate and xanthate, which is applied in the field of preparation of xanthate alkyl hydroxamate, can solve the problem that it is difficult to extract copper sulfide and copper oxide at the same time, the cost of medicine is high, and the Oxidized ore collectors are few and other problems, so as to achieve the effect of easy operation, efficient recovery and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

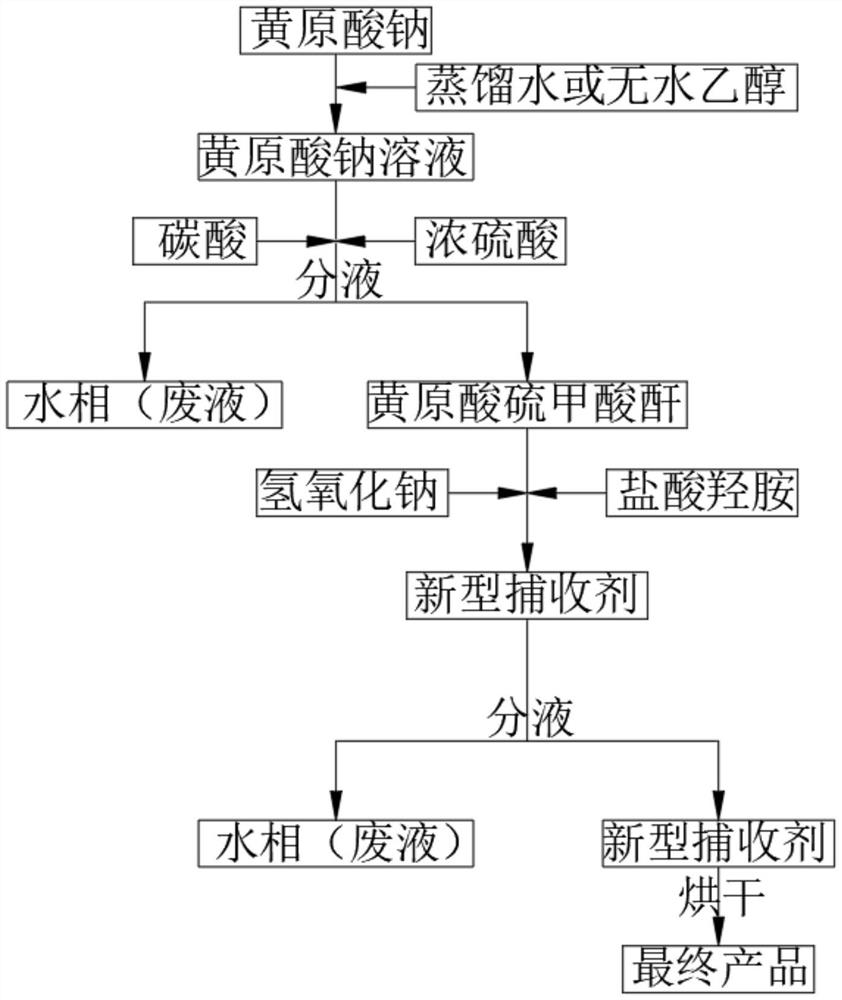

[0025] The invention provides a kind of preparation method of xanthate alkylhydroxamate, it comprises the following steps:

[0026] Step (1): Put the xanthate in a beaker, add distilled water or absolute ethanol, and heat in a water bath under stirring conditions to quickly and completely dissolve the xanthate;

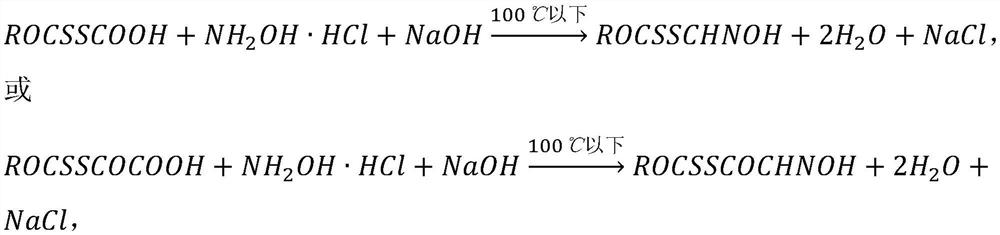

[0027] Step (2): Add a certain amount of carbonic acid and concentrated sulfuric acid to the dissolved xanthate solution to dehydrate the xanthate and carbonic acid to generate a medicament. The reaction formula is as follows:

[0028] Among them, R is selected from C 1 -C 5 Alkyl groups, such as methyl, ethyl, propyl, butyl, isobutyl, pentyl, isopentyl, neopentyl.

[0029] When adding a certain amount of oxalic acid and concentrated sulfuric acid to the dissolved xanthate solution. , make xanthate and oxalic acid undergo dehydration reaction to generate medicament, and its reaction formula is as follows:

[0030] Among them, R is selected from C 1 -C 5 Alky...

Embodiment 1

[0052] Put 172.12g of sodium butylxanthate into a 500ml beaker, add 150ml of distilled water, heat and dissolve in a water bath for 40min at a magnetic stirring speed of 250r / min, and a temperature of 60°C to obtain a sodium butylxanthate solution. Then dropwise the concentrated sulfuric acid of 25.62ml (concentration is 98%) and the oxalic acid of 90g in the solution with the speed of 2 drops / second, maintain reaction temperature to be 105 ℃, react 18h under the condition that magnetic stirrer stirring speed is 250r / min . The product after the reaction was transferred to a separatory funnel and left to stand for 5h, then the organic phase was taken, and the organic phase was washed 3 times with distilled water. Add 69.45 g of hydroxylamine hydrochloride and 40 g of sodium hydroxide to the filtered organic phase (xanthic acid thioformic anhydride), maintain the reaction temperature at 70° C., and react for 18 hours at a magnetic stirrer stirring speed of 250 r / min. The reacte...

Embodiment 2

[0054] Put 15.61g of sodium butyl xanthate into a 500ml beaker, add 150ml of absolute ethanol, heat and dissolve in a water bath for 40min at a magnetic stirring speed of 250r / min and a temperature of 60°C to obtain sodium butyl xanthate solution. Then add dropwise the vitriol oil of 2.56ml (concentration is 98%) and the oxalic acid of 9.0g in the solution with the speed of 2 drops / second, maintain reaction temperature to be 60 ℃, the magnetic stirrer stirring speed is the reaction under the condition of 250r / min 18h. The product after the reaction was transferred to a separatory funnel and left to stand for 5h, then the organic phase was taken, and the organic phase was washed 3 times with distilled water. Add 7 g of hydroxylamine hydrochloride and 4 g of sodium hydroxide to the filtered organic phase (xanthic acid thioformic anhydride), maintain the reaction temperature at 70° C., and react for 18 h at a magnetic stirrer stirring speed of 250 r / min. The reacted product was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com