Preparation method of polyphenylene sulfide sulfone ketone fibers

A technology of polyphenylene sulfide and sulfone ketone, which is applied in the field of preparation of polyphenylene sulfide sulfone ketone fibers, can solve the problems of high-quality product industrialization difficulty, low average molecular weight of polymerization products, high polymerization cost, etc., and achieve inhibition of oxidative fracture , Improve flexibility, improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method (abbreviation method) of polyphenylene sulfide sulfone ketone fiber, it is characterized in that, this method comprises the following steps:

[0032] (1) Ketogenic PPS: Using metal oxide as a catalyst, the fiber-grade PPS resin, metal oxide and carboxylic acid are reacted by screw extrusion and blended and melted in a screw extruder by one-step in-situ spinning to prepare ketone-containing PPS. PPS tow; or use the screw extrusion reaction of fiber grade PPS resin, metal oxide and carboxylic acid to blend, melt and granulate in the screw extruder to prepare ketone-containing PPS granules, and then use ketone-containing PPS granules as raw materials for granulation Melt spinning to prepare ketone-containing PPS tow; the carboxylic acid is a dicarboxylic acid or a polycarboxylic acid;

[0033] Preferably, in step (1), the dicarboxylic acid is terephthalic acid, naphthalene dicarboxylic acid, cyclohexanedicarboxylic acid, ...

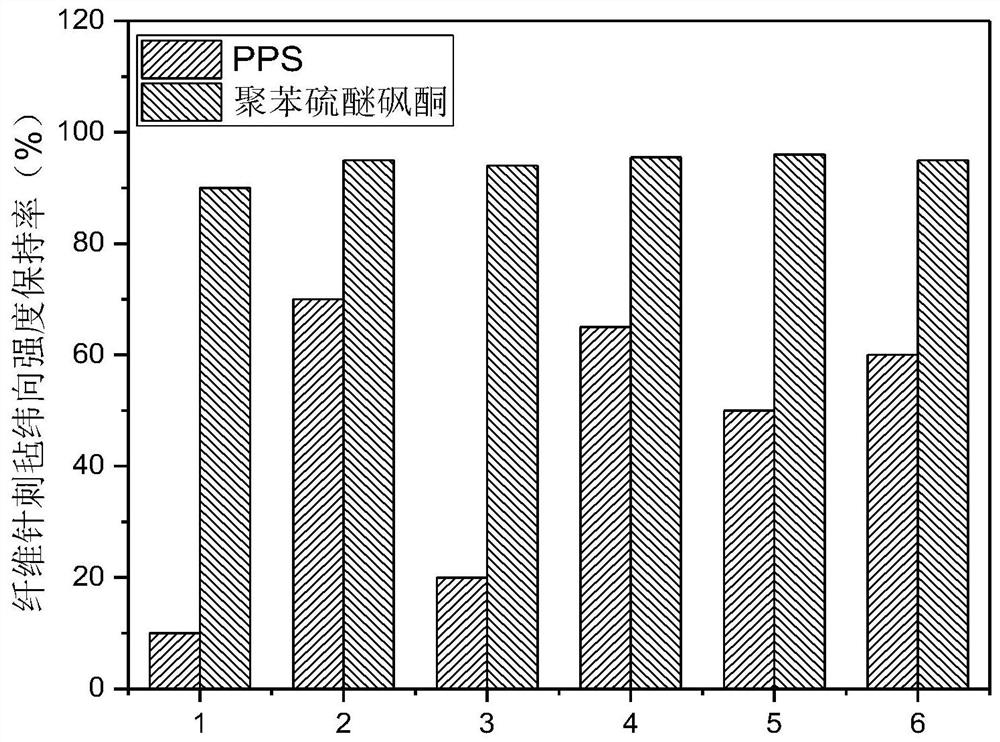

Embodiment 1

[0052] (1) 5g terephthalic acid, 1g TiO 2 Blending and melting granulation with 494gPPS resin in a twin-screw extruder at high temperature, the feeding port temperature of the screw extruder is 265°C, the die head temperature is 310°C, and the temperature in the middle zone of the spinning screw is controlled at 300-325°C to prepare ketone-containing PPS resin chips;

[0053] Then melt-spin ketone-containing PPS resin slices to obtain ketone-containing PPS tow; the temperature of the feed port is 305°C, the temperature of the second zone is 320-330°C, the third zone is 325-335°C, and the fourth zone is 325-335°C. The temperature is 315°C; the hot stretching temperature is 95°C, and the stretching ratio is 3.5 times;

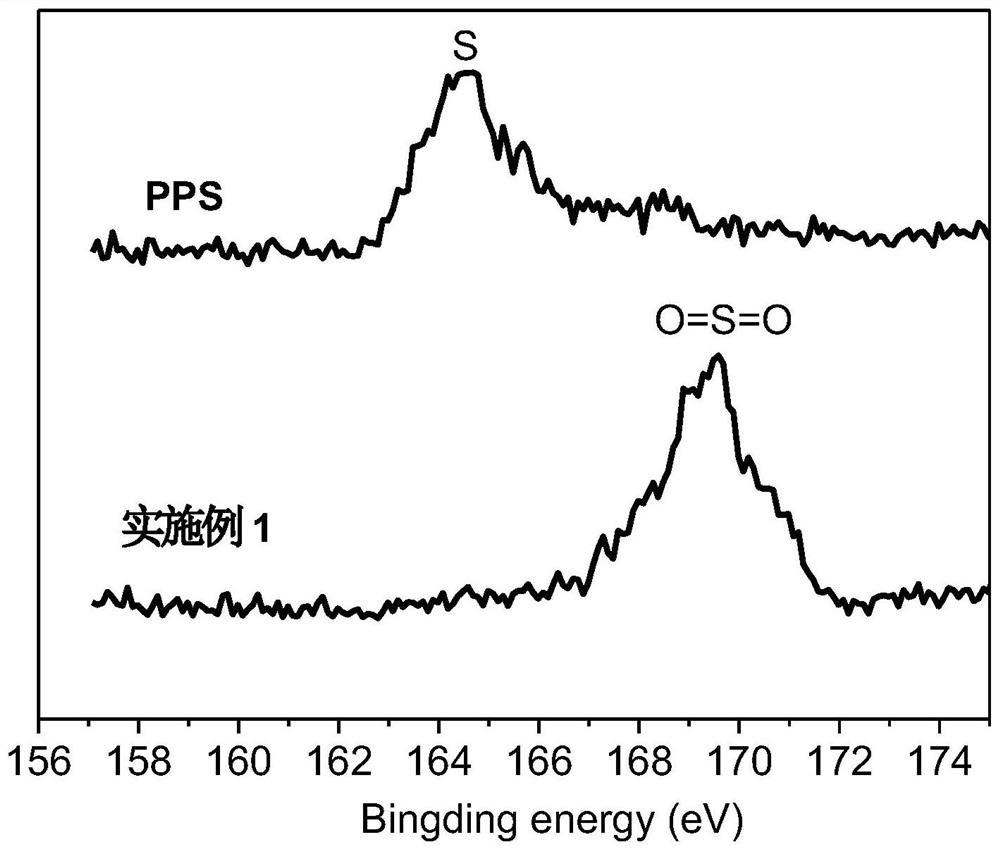

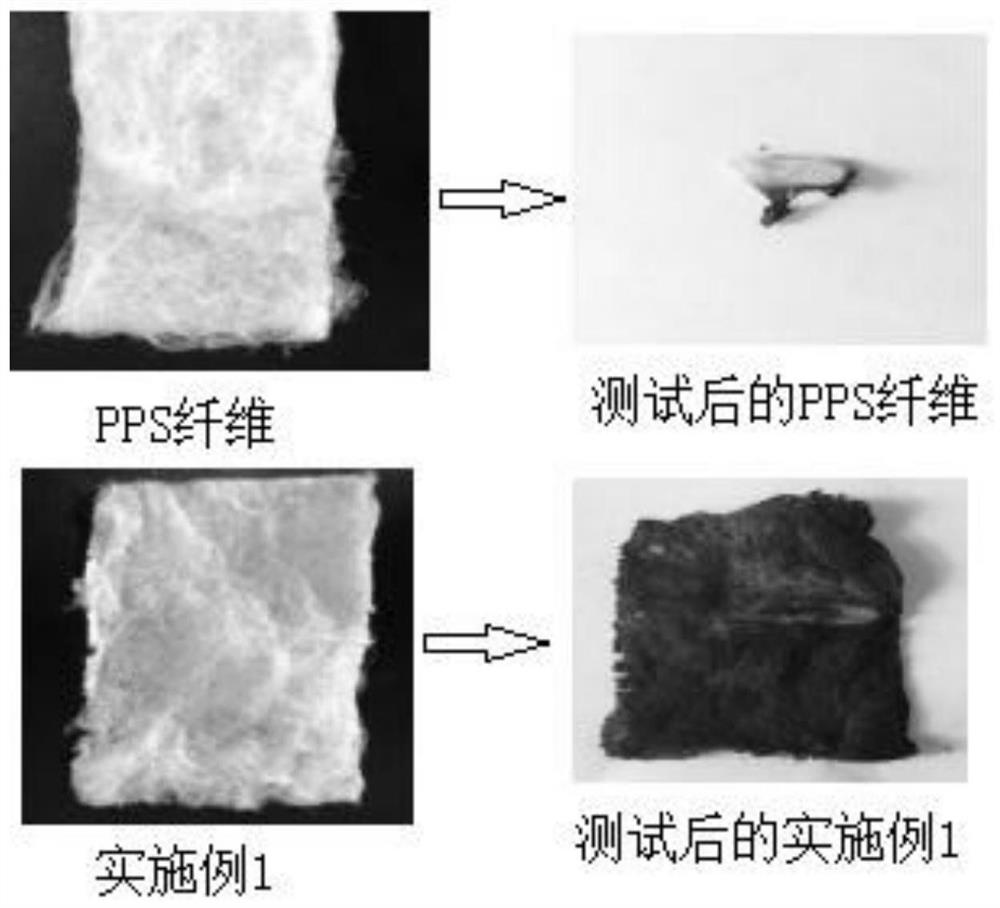

[0054] (2) Immerse the ketone-containing PPS tow (tensile strength 5.5CN / dt, elongation at break 28%) into 10wt% H 2 o 2 , 10wt% acetic acid, 0.1wt% HCl in water, the mass ratio of ketone-containing PPS tow and oxidant solution is 1:5, soaked at 60°C for 30min...

Embodiment 2

[0064] (1) 3g malonic acid, 0.5g SnO 2 Blending and melting granulation with 496.5g PPS resin in a twin-screw extruder at high temperature, the feed port temperature of the screw extruder is 260°C, the die head temperature is 315°C, and the temperature in the middle zone of the spinning screw is 295-320°C to prepare ketone-containing PPS Resin chips;

[0065] Then melt-spin ketone-containing PPS resin slices to obtain ketone-containing PPS tow; the temperature of the feed port is 305°C, the second zone is 325°C, the third zone is 325°C, the fourth zone is 330°C, and the die head temperature is 315°C; The stretching temperature is 100°C, and the stretching ratio is 4 times;

[0066] (2) Immerse ketone-containing PPS tow (tensile strength 5.3CN / dt, elongation at break 32%) in the benzene of 15wt% benzoyl peroxide, 5wt% butyric acid, 0.1wt% benzenesulfonic acid, containing The mass ratio of the ketone PPS tow to the oxidizing agent solution is 1:11, soaked at 60°C for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com