Preparation method of high-conductivity and high-elasticity three-dimensional graphene material

A graphene, high-elasticity technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve problems that are not suitable for large-scale manufacturing, expensive equipment and energy, graphene oxide removal, etc., to improve mechanics and electricity Performance, improvement of reduction degree, effect of preventing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

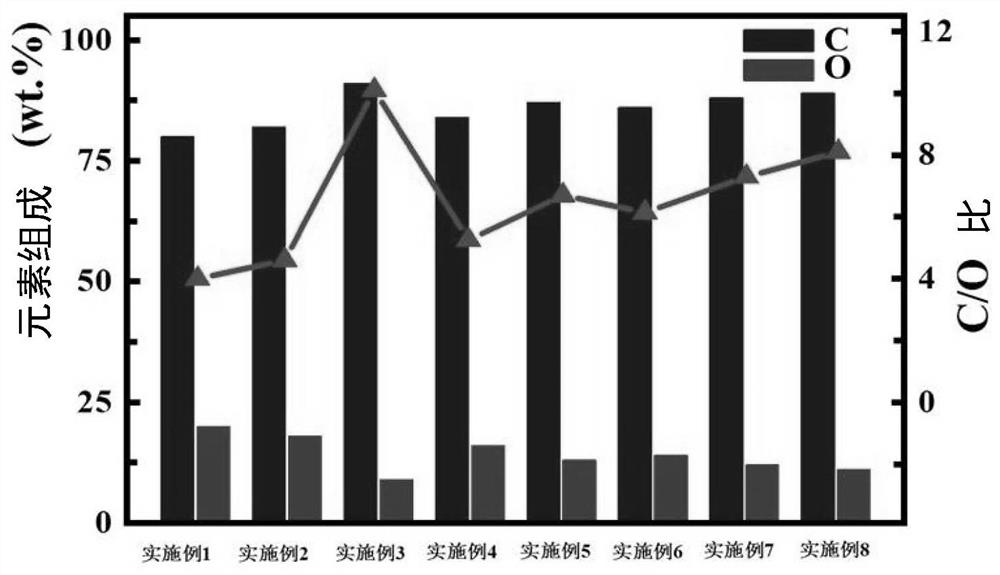

Embodiment 1

[0053] Graphene oxide was synthesized by a modified Hummers method. Graphite powder (4.0 g, 325 mesh) and sodium nitrate (4.0 g) were added to concentrated sulfuric acid (192 mL), and stirred slowly in an ice bath for 20 minutes. Potassium permanganate (24.0 g) was then slowly added to keep the temperature of the suspension below 5° C. for 2 hours, and then the suspension was heated to 35° C. for two hours to form a thick slurry. Add deionized water (400mL) gradually afterwards, heat to 80 ℃ and keep warm for 20 minutes, then add 20 milliliters of hydrogen peroxide (30%), and finally add water to dilute the mixed solution to 1000 milliliters, leave it for a day, and finally put the product into a dialysis bag for dialysis to neutral;

[0054] Afterwards, the three-dimensional porous graphene material was prepared by hydrothermal reduction method, and 30 mL of graphene oxide solution (4 mg / mL) was ultrasonically treated for 1 hour (2 kW), sealed in a 50 mL tetrafluoroethylene a...

Embodiment 2

[0057] The preparation method in Example 2 is basically the same as that in Example 1, except that a small amount of water vapor (2 μg) is introduced before heating in a vacuum furnace with two temperature zones. The graphene oxide solution preparation method and reduction hydrothermal method are the same as in Example 1, and then the above-mentioned sample is placed in the low-temperature zone of the double-zone vacuum furnace, and the metal aluminum powder is placed in the high-temperature zone. Use a mechanical pump to evacuate to about 0.5Pa to remove the air in the furnace. Then a small amount of water vapor (2 μg) was introduced, and then the metal aluminum powder was heated to 800°C, the sample was heated to 200°C, and the heating was started at the same time, and the holding time was 4 hours, and finally the three-dimensional graphene material was obtained. The electrical conductivity of gained three-dimensional graphene material is 675.5S / m, and elastic modulus is 145...

Embodiment 3

[0059] The preparation method in Example 3 is basically the same as that in Example 2, except that a crosslinking agent glycolic acid is added to the graphene oxide solution at a concentration of 1 mg / ml. During the reaction, 30ml of a mixed solution containing glycolic acid (1mg / mL) and graphene oxide (4mg / mL) was stirred and sonicated for 1 hour (2kW) and sealed in a 50ml tetrafluoroethylene autoclave, then Put into 120 ℃ oven and keep for 12 hours, after cooling to room temperature, wash and soak the formed hydrogel with ethanol aqueous solution (20wt.%), then obtain three-dimensional porous graphene material by freeze-drying process, after the above-mentioned sample Put it in the low temperature zone of the double-zone vacuum furnace, and put the metal aluminum powder in the high temperature zone. Use a mechanical pump to evacuate to about 0.5Pa to remove the air in the furnace. After injecting a small amount of water vapor (2μg), heat the metal aluminum powder to 800°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap