Hollow metal oxide microspheres and preparation method and drug sustained release application thereof

An oxide and metal technology, applied in the field of hollow metal oxide microspheres, can solve the problems of silver-based antibacterial agents, such as easy oxidative discoloration, easy aging due to light, complicated process, etc. The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

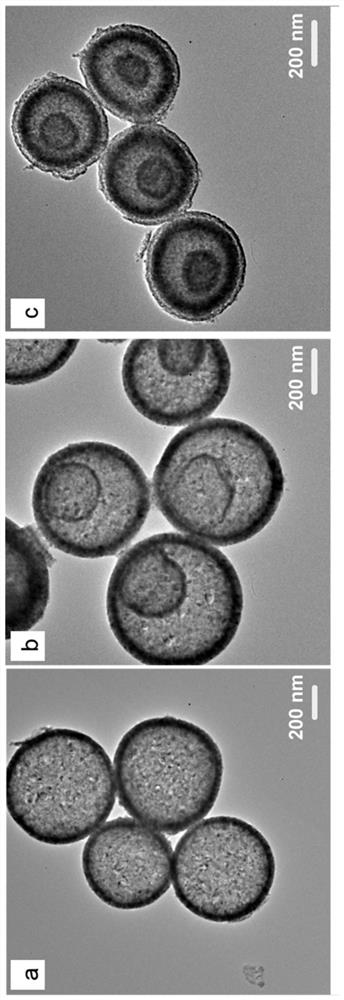

[0057] Hollow metal oxide microspheres can be prepared by template method, layer coating method and other methods. In some embodiments of the present invention, a method for preparing hollow metal oxide microspheres using carbon spheres as templates is provided. The method is based on the method described in references Xiaoyong Lai, Jun Li, Brian A. Korgel, Zhenghong Dong, Zhenmin Li, FabingSu, JiangDu, and Dan Wang*.Angew.Chem.Int.Ed.2011,50,2738 Made improvements. Specifically, the method includes: dehydrating and polycondensing 130g of sucrose at 200°C to obtain carbon microspheres, taking 0.6g of carbon microspheres, adding them to 30ml 3mol / L TiCl 4 In the solution, by adjusting the adsorption temperature and adsorption time, vacuum filtration, oven drying at 80°C for 12 hours, and calcining in a muffle furnace at 500°C to obtain carrier materials with different shell structures. Under the same calcination conditions, if adsorption at room temperature is used for 6 hour...

Embodiment 1

[0068] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally reacted in an autoclave at 200°C for about 130min, cooled naturally, filtered with suction, washed with water and ethanol several times, and dried in an oven at 80°C for 24h. Carbon spheres are about 3 μm in diameter.

[0069] 0.6g carbon spheres (as the preparation of TiO 2 Hollow sphere template) uniformly dispersed in 30mL 3M TiCl 4 in solution. Stir at 25°C for 2h, then filter with suction, wash with deionized water three times, and dry in an oven at 80°C for 12h. Place the obtained solid powder in a muffle furnace, raise the temperature to 500°C at 2°C / min, keep it warm for 3h, and obtain a single-shell TiO after natural cooling. 2 hollow ball. Its transmission electron microscope pictures are shown in figure 1 a.

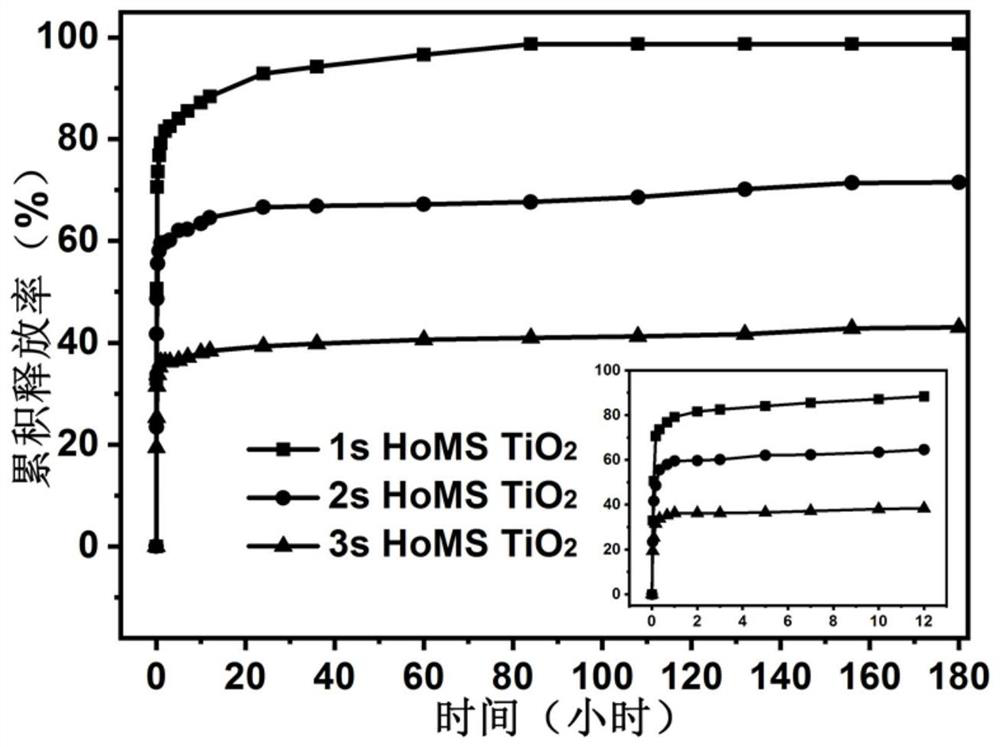

[0070] 8 mg of prepared single-shell TiO 2 The hollow spheres were placed in a vacuum drying oven, vacuumed for 30 minutes, then 2 mL of 10 wt % methylisothiazolinone an...

Embodiment 2

[0075] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally reacted in an autoclave at 200°C for about 130min, cooled naturally, filtered with suction, washed with water and ethanol several times, and dried in an oven at 80°C for 24h. Carbon spheres are about 3 μm in diameter.

[0076] Disperse 0.6g carbon sphere template evenly in 3M TiCl 4 in solution. At 40°C, stir and age for 8 hours, then filter with suction, wash with deionized water for 3 times, dry in an oven at 80°C for 12 hours, put the obtained solid powder in a muffle furnace and raise the temperature to 500°C at 2°C / min, and keep it warm for 3 hours , double-shelled TiO was obtained after natural cooling 2 hollow ball. Its transmission electron microscope pictures are shown in figure 1 b.

[0077] 8 mg of prepared double-shell TiO 2 The hollow spheres were placed in a vacuum drying oven, vacuumed for 30 minutes, then 2 mL of 10 wt % methylisothiazolinone antibacterial agent was added,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com