Mildewproof silicone sealant and preparation method thereof

A silicone sealant and anti-mildew technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high cost, poor anti-mildew effect, high hardness of epoxy resin, etc., and achieve displacement Moderate ability, long-lasting anti-mildew effect and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

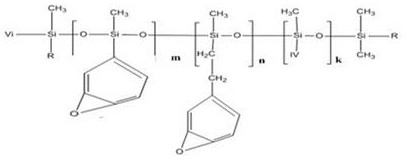

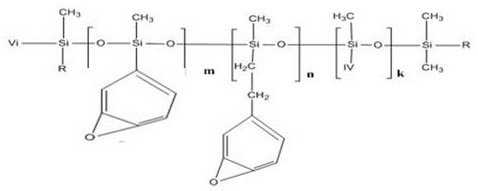

Method used

Image

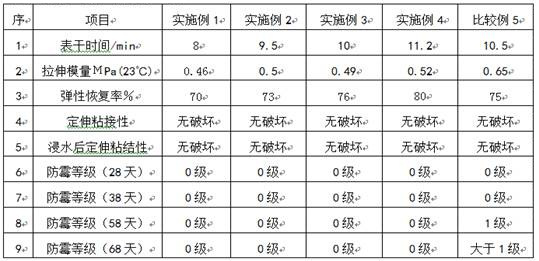

Examples

Embodiment 1

[0023] (a) Coal ash modification treatment: first ground the modified pulverity ash with purity ≥99% Ai2O3 ball and purity ≥99% SiO2 square block, and sieve 5 μm or less with fly ash with gas flow sieving, and then The rotary permanent magnet removal of the iron ion in powder, and modified according to 0.1 to 0.2% γ-aminopropyltriethoxysilane and 0.2 to 0.5% octadanoic acid, control particle size ≤ 5 μm, whiteness ≥ 88%, iron ion content is ≤0.01%.

[0024] (b) Preparation of mildew silicone sealant: 26.74 parts of dihydroxy polysiloxane, 25 parts of acrylic acid modified silicone resin, 40 modified pulse gray, 3 copies of titanium dioxide, in the material fluid temperature at 120 ~ 150 ° C , The vacuum requires -0.08MPa ~ -0.1MPa, dehydration 3 to 5 h, the cooling material temperature is below 50 ° C, and then adds 4 of Tetracycline Qalani, 2,2'-Di Sulfur Double. (N-methylbenzamide) 0.2 parts, 3.5 parts of methyl tributyl oxime silane, 0.5 parts of vinyl tributtyzine silane, in v...

Embodiment 2

[0026] (a) Coal ash modification treatment: first ground the modified pulverity ash with purity ≥99% Ai2O3 ball and purity ≥99% SiO2 square block, and sieve 5 μm or less with fly ash with gas flow sieving, and then The rotary permanent magnet removal of the iron ion in powder, and modified according to 0.1 to 0.2% γ-aminopropyltriethoxysilane and 0.2 to 0.5% octadanoic acid, control particle size ≤ 5 μm, whiteness ≥ 88%, iron ion content is ≤0.01%.

[0027] (b) Antiofillet silicone sealing gum Preparation: 29.84 parts of dihydroxy polysiloxane, 23 of acrylic modified silicone resin, 39 copies of modified fly ash, 2.3 parts of titanium dioxide, in the material fluid temperature at 120 ~ 150 ° C , The vacuum requires -0.08MPa ~ -0.1MPa, dehydrated 3 to 5 h, the cooling material temperature is below 50 ° C, then adds 0.28 quadramidal quadraminated Qiarum, 2,2'-disulfide double (N-methylbenzamide) 0.3 parts, 3.5 parts of methyl tributyl oxime silane, 1.0 parts of propyl tributone oxim...

Embodiment 3

[0029] (a) Coal ash modification treatment: first ground the modified pulverity ash with purity ≥99% Ai2O3 ball and purity ≥99% SiO2 square block, and sieve 5 μm or less with fly ash with gas flow sieving, and then The rotary permanent magnet removal of the iron ion in powder, and modified according to 0.1 to 0.2% γ-aminopropyltriethoxysilane and 0.2 to 0.5% octadanoic acid, control particle size ≤ 5 μm, whiteness ≥ 88%, iron ion content ≤ 0.01%;

[0030] (b) Preparation of mildew silicone sealant: 33.06 parts of dihydroxy polysiloxane, 22 acrylic modified silicone resins, 37 modified fly ash, 1.8 parts of titanium dioxide, and in the material fluid temperature at 120 ~ 150 ° C , The vacuum requires -0.08MPa ~ -0.1MPa, dehydrated 3 to 5 h, the cooling material temperature is below 50 ° C, and then the tetramethyl dioxide Qalan is 0.24, 2, 2'-di sulfur double. (N-methylbenzamide) 0.4 parts, 3.5 parts of methyl tributyl oxime silane, 1.2 parts of tetrabutyl silane, in vacuum -0.08 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com