Method for preparing core-shell composite sulfide material through two-step method

A composite, sulfide technology, applied in chemical instruments and methods, cobalt sulfide, iron sulfide, etc., can solve the problems of difficult controllability of observation and monitoring experimental technology, strong dependence on experimental equipment, high risk, etc. Improved voltage plateau characteristics, improved effective discharge capacity, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

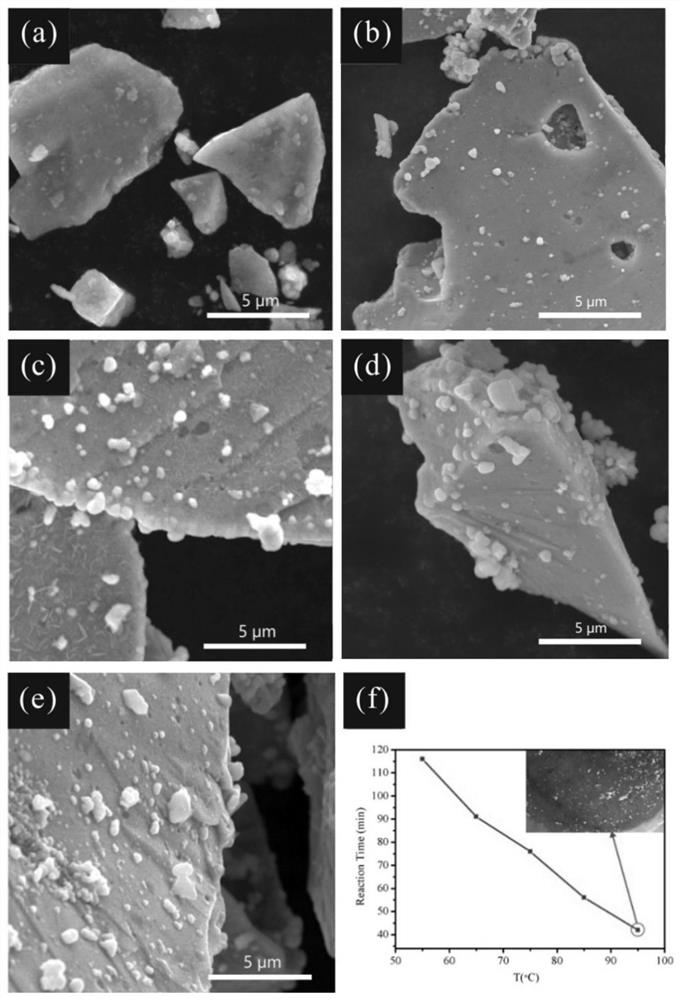

[0060] Sulfurization experiment of precursors with low cobalt concentration;

[0061] The preparation process of precursor is consistent with embodiment 1, and concrete condition parameter is as follows:

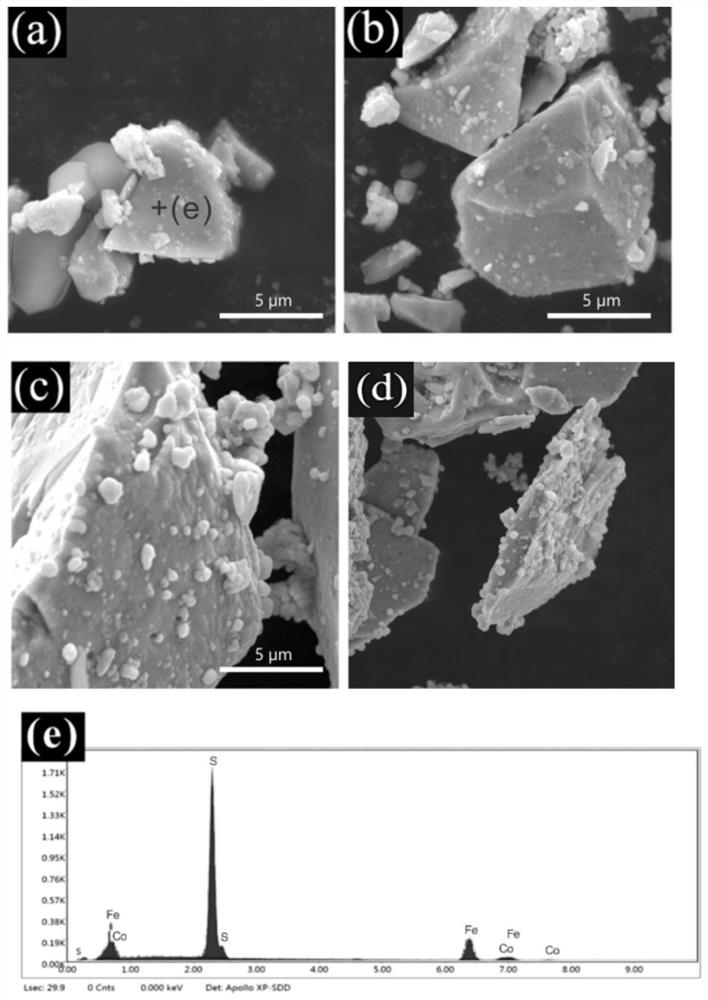

[0062] In the experiment, the reaction temperature was set at 75°C, and the concentration was 12g L -1 CoSO 4 54 ml and 20 g acidified pretreated FeS 2 The powder is the raw material, and the pH value is studied at 11; stirring; then in the water bath solution, the temperature is raised to 60-85°C at a heating rate of 5°C / min, stirred and kept for a while; after the plating solution becomes clear; solid-liquid separation; Precursors of core-shell composite sulfide materials. The phase analysis of the obtained electroless cobalt plating product is as follows: Figure 5 Shown in CP-1(Co).

[0063] The prepared product plus elemental sulfur powder undergoes vulcanization reaction (sulfur powder is sufficient), the first stage is 10 ℃ min -1 The heating rate was increased ...

Embodiment 6

[0068] Vulcanization experiment of precursors with high cobalt concentration;

[0069] The preparation process of precursor is consistent with embodiment 1, and concrete condition parameter is as follows:

[0070] In the experiment, the reaction temperature was set at 75°C, and the concentration was 12g L -1 CoSO 4 110 ml and 20 g acidified pretreated FeS 2 The powder is the raw material, and the pH value is studied at 11; stirring; then in the water bath solution, the temperature is raised to 60-85°C at a heating rate of 5°C / min, stirred and kept for a while; after the plating solution becomes clear; solid-liquid separation; Precursors of core-shell composite sulfide materials. The phase analysis of the obtained electroless cobalt plating product is as follows: Figure 5 Shown in CP-2(Co).

[0071] The prepared product plus elemental sulfur powder undergoes vulcanization reaction (sulfur powder is sufficient), the first stage is 10 ℃ min -1 The heating rate was increase...

Embodiment 7

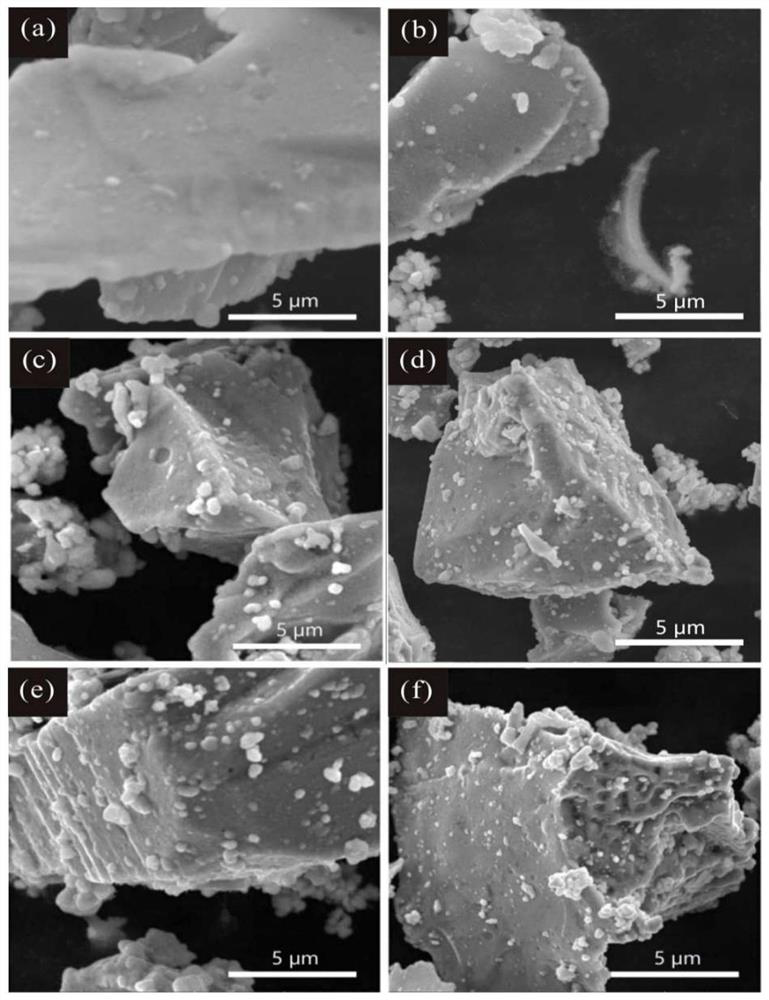

[0073] Vulcanization experiments of precursors with high cobalt concentration;

[0074] The preparation process of precursor is consistent with embodiment 1, and concrete condition parameter is as follows:

[0075] In the experiment, the reaction temperature was set at 75°C, and the concentration was 12g L -1 CoSO 4 170 ml and 20 g of pretreated FeS 2 The powder is the raw material, and the pH value is studied at 11; stirring; then in the water bath solution, the temperature is raised to 60-85°C at a heating rate of 5°C / min, stirred and kept for a while; after the plating solution becomes clear; solid-liquid separation; Precursors of core-shell composite sulfide materials. The phase analysis of the obtained electroless cobalt plating product is as follows: Figure 5 Shown in CP-3(Co).

[0076] The prepared product plus elemental sulfur powder undergoes vulcanization reaction (sulfur powder is sufficient), the first stage is 10 ℃ min -1 The heating rate was increased to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com