Formula, preparation method and production equipment of high-tensile PBT (Polybutylene Terephthalate) material

A production equipment and high-tensile technology, applied in the field of PBT materials, can solve the problems of weak tensile properties, small application range, and insufficient tensile properties of PBT materials, so as to improve mechanical properties, improve physical and chemical properties, improve hardness and durability. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

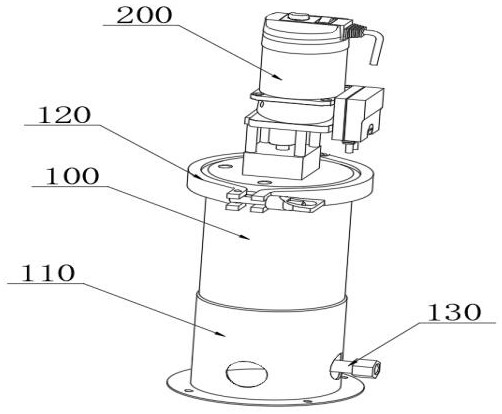

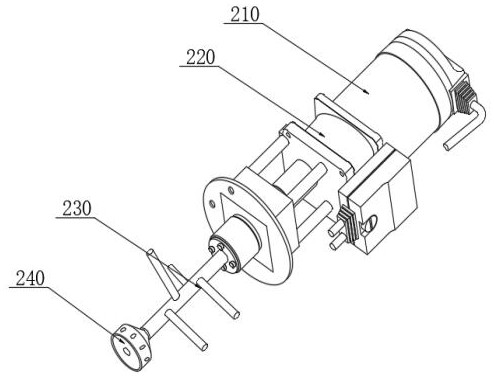

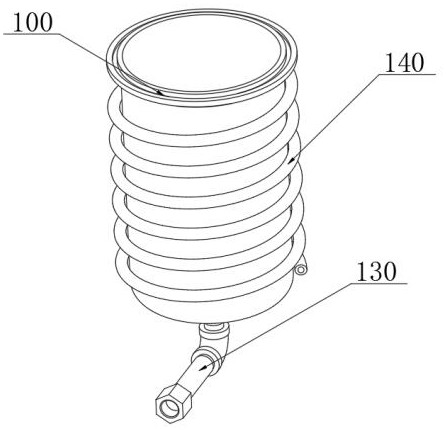

[0033] combine Figure 1-5 As shown, the formula and preparation method of a high-tensile PBT material provided by the present invention comprise the following steps: S1: using 1.4-butanediol and terephthalic acid dicarboxylate to carry out transesterification reaction to generate terephthalic acid dibutyl ester, and remove methanol, and then carry out polycondensation reaction to produce PBT resin raw material;

[0034] S2: The following mass fractions of raw reaction materials are used: 45-50 parts of PBT resin raw materials, 0.3-0.7 parts of acrylic polymer chain extender ADR, 0.3-0.8 parts of coupling agent and 0.02-0.04 parts of antioxidant Inject into the production equipment of PBT material, preheat the temperature to 230-240°C and keep stirring, the coupling agent is aminopropyltriethoxysilane KH-550, methacryloxy and titanate coupling agent One or more combinations in 101, the antioxidant is a compound of hindered phenolic antioxidant 1010 and phosphite antioxidant 6...

Embodiment 2

[0045] The difference with Example 1 is that, S1: Use 1.4-butanediol and terephthalic acid dicarboxylate to carry out transesterification reaction to generate dibutyl terephthalate, and remove methanol, and then carry out polycondensation reaction to produce PBT resin raw material;

[0046] S2: The following mass fractions of raw reaction materials are used: 45-50 parts of PBT resin raw materials, 0.7-0.9 parts of acrylic polymer chain extender ADR, 0.8-1.0 parts of coupling agent and 0.02-0.04 parts of antioxidant Inject into the production equipment of PBT material, preheat and control the temperature to 230-240°C and keep stirring. The coupling agent is aminopropyltriethoxysilane KH-550, methacryloxy and titanate coupling agent One or more combinations in the joint agent 101, the antioxidant is a compound of hindered phenolic antioxidant 1010 and phosphite antioxidant 626 mixed according to the mass component 2:1.2;

[0047] S3: The pressurization interface of the device i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com