Method for producing pectinase preparation through solid-state fermentation of penicillium

A technology of pectinase preparation and solid-state fermentation, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problem of limiting the application range and effect of pectinase, the inability to achieve large-scale production, and the ability of strains to accumulate products Low-level problems, to achieve the effect of not being easy to pollute a large area, easy to control the fermentation process, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

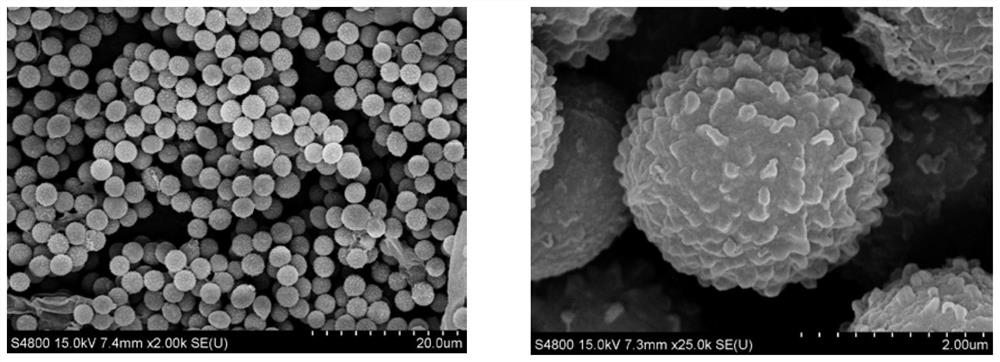

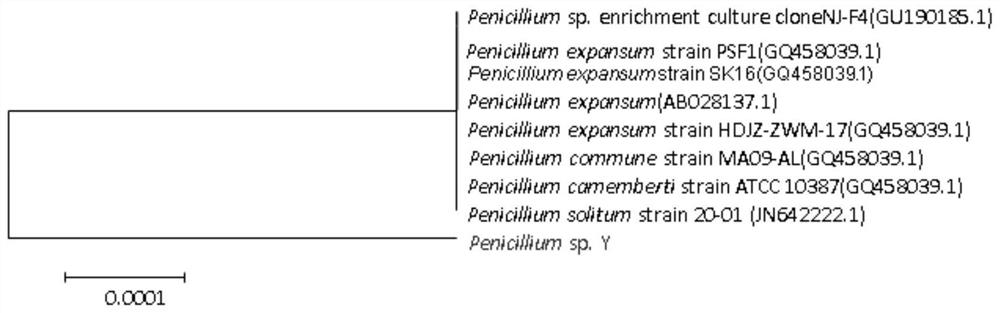

[0033] Isolation, Screening and Identification of Penicillium sp. Y

[0034] (1) Isolation of strains

[0035] 5-10 g of soil samples collected from different farmland sampling points in the southern suburbs of Changzhou City, Jiangsu Province, 5-10 cm below the soil surface were stored in sterile 20 mL sealed bags, and stored in a refrigerator at 4 °C for subsequent screening of strains. Weigh 3-5g of soil samples from different sampling points and add them into 250ml Erlenmeyer flasks filled with 50ml sterile normal saline, mix well, shake fully and let stand for 30-60min, take 2-5ml of supernatant and add them into 50ml conical flasks In the 250ml Erlenmeyer flask of the initial enrichment medium, culture it on a constant temperature shaker at 120rpm min-1 at 38-40°C for 3-5 days, then transfer 5ml of the liquid medium to 45ml of fresh inorganic salt screening flask. A 250ml Erlenmeyer flask of culture medium was used for subsequent subcultures. Subculture for several tim...

Embodiment 2

[0048] By selecting the optimal solid substrate for the growth of Penicillium sp.Y, different solid-state fermentation culture substrates were used: rice bran, soybean cake powder, bran, soybean meal, cottonseed cake powder, rapeseed cake powder, and each group of experiments was compared three times. The operation is as follows:

[0049] In the ultra-clean workbench, use an inoculation loop to pick a few bacteria from the plate and insert them into the sterilized seed medium, and insert them into the above-mentioned rice bran at an inoculation amount of 2% after culturing to the logarithmic growth phase. , bean cake powder, bran, soybean meal, cottonseed cake powder, rapeseed cake powder as solid matrix fermentation medium, cultivated in a constant temperature incubator at 38°C for 3 days, and took samples to determine the enzyme activity produced by the strain.

[0050] This example shows that when soybean meal is used as the fermentation substrate, the pectinase activity pr...

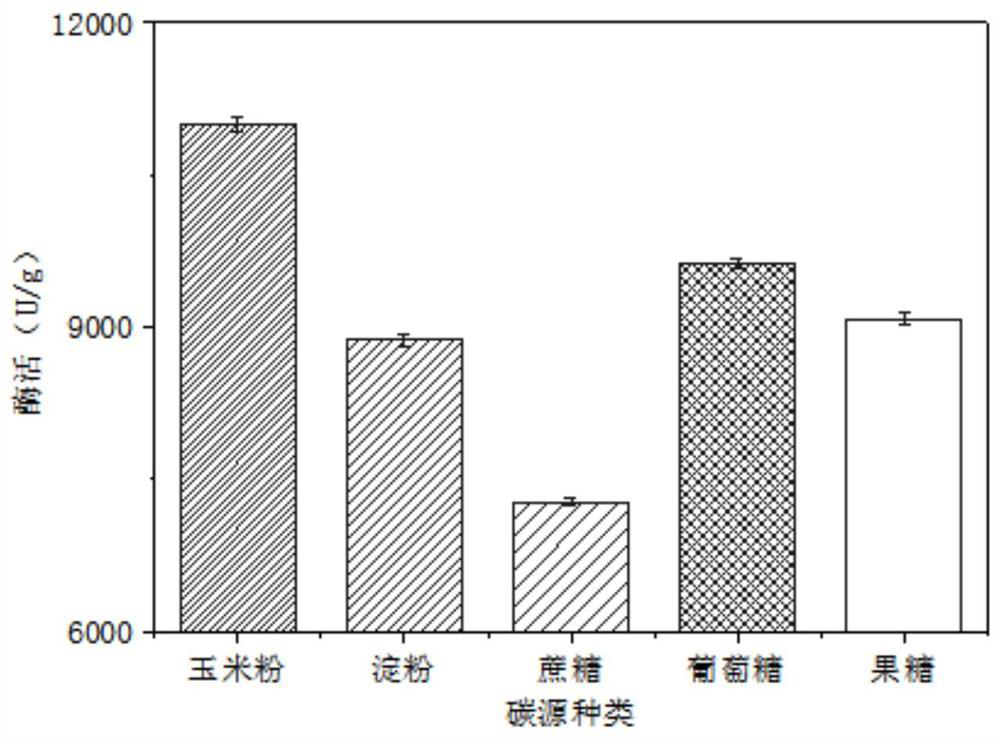

Embodiment 3

[0052] By determining the optimum carbon source and its concentration required by the Penicillium sp.Y strain in the fermentation process, corn flour, starch, sucrose, glucose and fructose were selected as the fermentation carbon source, and 1%, 2%, 4%, 6% and 8% carbon source concentrations were added to the fermentation medium, and each group of experiments was compared for 3 times. The specific experimental operations were as follows:

[0053] During the preparation of the fermentation medium, corn flour, starch, sucrose, glucose and fructose were selected as the single carbon source and other variables were kept unchanged. After the medium was prepared, it was sterilized at 115°C for 30 minutes. In the ultra-clean workbench, use a sterilized gun tip to draw 2mL of seed liquid into the fermentation medium, then use a sterile glass rod to stir the medium evenly and place it in a 38°C constant temperature incubator for 3 days, then take a sample for measurement. enzyme activi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com