Composite sponge material and preparation method thereof, and application of composite sponge material in treatment of high-salt high-calorific-value wastewater

A technology of composite sponge and calcium salt, which is applied in the field of composite sponge materials and its preparation, can solve the problems of pharmacy cost, unbearable time cost, shortened service life of equipment, and difficulty in meeting emission standards, so as to achieve controllable cost and reduce possibility , The effect of reducing the amount of solid waste generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

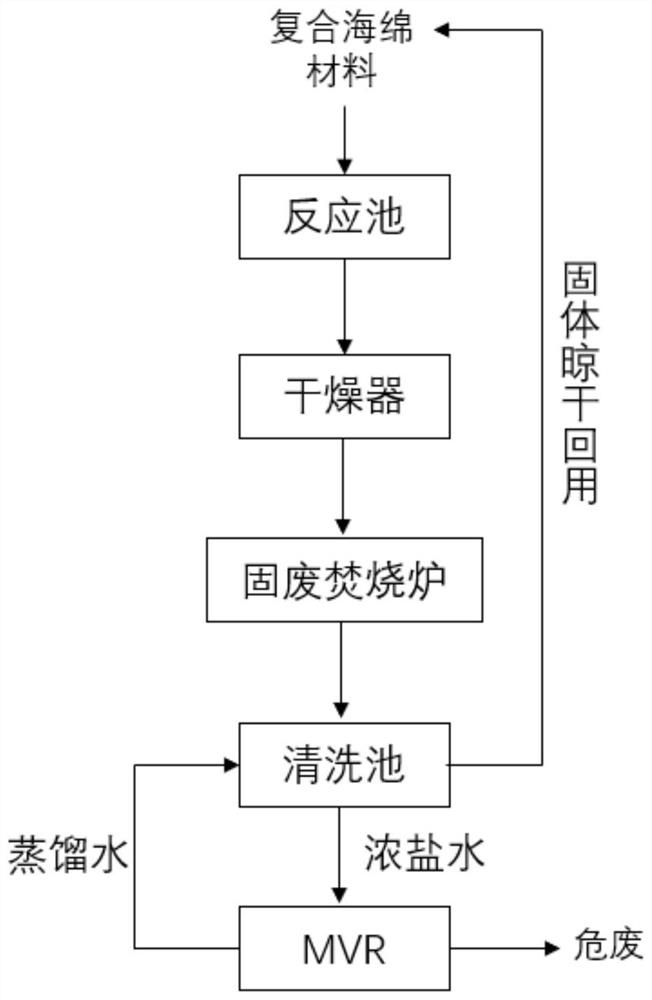

Method used

Image

Examples

Embodiment 1

[0055] A batch of concentrated wastewater with high salinity and high calorific value after three-effect evaporation needs to be treated. The water quality indicators of the concentrated pharmaceutical wastewater with high salinity and high calorific value: COD is 628800mg / L, salt content is 240g / L, and calorific value is 3650J / L kg. (The source of the waste water is Hongbaoli Group Sodium Phenate Concentrated Wastewater.)

[0056] Composite sponge material, including the following mass fractions:

[0057] Inorganic drying agent 85%;

[0058] Organic curing coagulant 15%;

[0059] The mass fraction of each substance in the inorganic drying agent is as follows:

[0060] Calcium salt 45%; the mass ratio of calcium oxide, calcium sulfate, calcium sulfate hemihydrate, calcium hydroxide, and calcium carbonate in calcium salt is: 1:0:1:1:1

[0061] Aluminum salt 15%; the mass ratio of aluminum oxide, aluminum sulfate, and washed red aluminum mud in aluminum salt is 1:1:1;

[00...

Embodiment 2

[0068] A batch of concentrated wastewater with high salinity and high calorific value after three-effect evaporation needs to be treated. The water quality indicators of the concentrated pharmaceutical wastewater with high salinity and high calorific value: COD is 628800mg / L, salt content is 240g / L, and calorific value is 3650J / L kg. (The source of the waste water is Hongbaoli Group Sodium Phenate Concentrated Wastewater.)

[0069] Composite sponge material, including the following mass fractions:

[0070] Inorganic drying agent 90%;

[0071] Organic curing coagulant 10%;

[0072] The mass fraction of each substance in the inorganic drying agent is as follows:

[0073] Calcium salt 35%; the mass ratio of calcium oxide, calcium sulfate, calcium sulfate hemihydrate, calcium hydroxide, and calcium carbonate in calcium salt is: 1:0.5:0.5:1:1

[0074] Aluminum salt 15%; the mass ratio of aluminum oxide, aluminum sulfate, and washed red aluminum mud in aluminum salt is 0.5:0.5:1...

Embodiment 3

[0081] A batch of concentrated wastewater with high salinity and high calorific value after three-effect evaporation needs to be treated. The water quality indicators of the concentrated pharmaceutical wastewater with high salinity and high calorific value: COD is 628800mg / L, salt content is 240g / L, and calorific value is 3650J / L kg. (The source of the waste water is Hongbaoli Group Sodium Phenate Concentrated Wastewater.)

[0082] Composite sponge material, including the following mass fractions:

[0083] Inorganic drying agent 95%;

[0084] Organic curing coagulant 5%;

[0085] The mass fraction of each substance in the inorganic drying agent is as follows:

[0086] Calcium salt 35%; the mass ratio of calcium oxide, calcium sulfate, calcium sulfate hemihydrate, calcium hydroxide, and calcium carbonate in calcium salt is: 1:1:0:1:1

[0087] Aluminum salt: 5%; the mass ratio in aluminum oxide, aluminum sulfate, and washed red aluminum mud in aluminum salt is 0.5:0.5:2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com